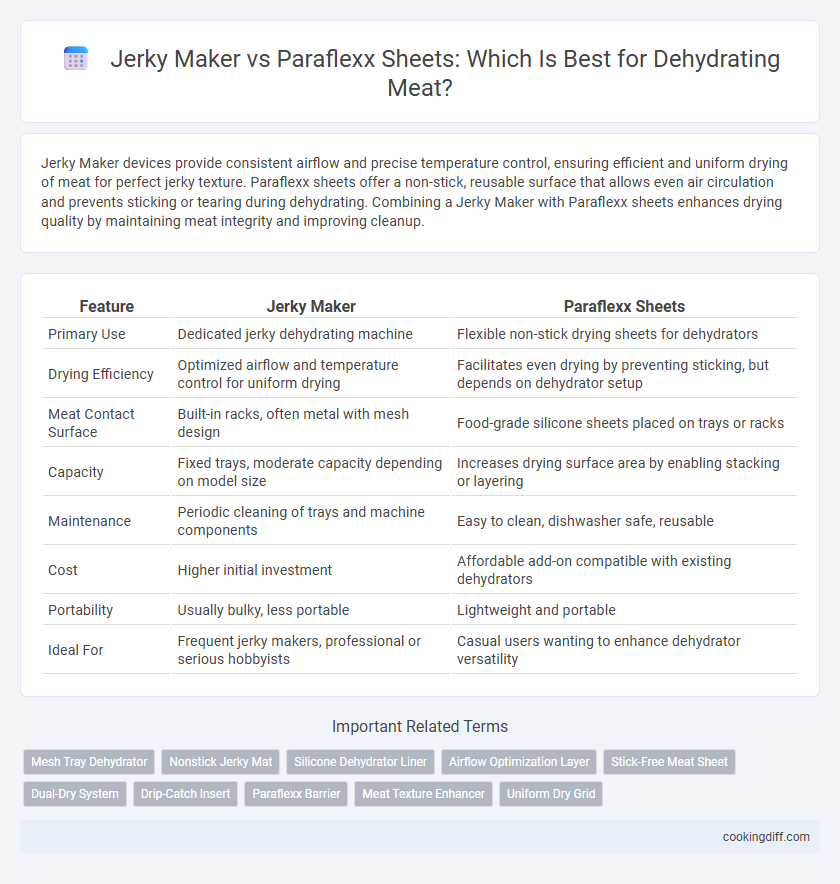

Jerky Maker devices provide consistent airflow and precise temperature control, ensuring efficient and uniform drying of meat for perfect jerky texture. Paraflexx sheets offer a non-stick, reusable surface that allows even air circulation and prevents sticking or tearing during dehydrating. Combining a Jerky Maker with Paraflexx sheets enhances drying quality by maintaining meat integrity and improving cleanup.

Table of Comparison

| Feature | Jerky Maker | Paraflexx Sheets |

|---|---|---|

| Primary Use | Dedicated jerky dehydrating machine | Flexible non-stick drying sheets for dehydrators |

| Drying Efficiency | Optimized airflow and temperature control for uniform drying | Facilitates even drying by preventing sticking, but depends on dehydrator setup |

| Meat Contact Surface | Built-in racks, often metal with mesh design | Food-grade silicone sheets placed on trays or racks |

| Capacity | Fixed trays, moderate capacity depending on model size | Increases drying surface area by enabling stacking or layering |

| Maintenance | Periodic cleaning of trays and machine components | Easy to clean, dishwasher safe, reusable |

| Cost | Higher initial investment | Affordable add-on compatible with existing dehydrators |

| Portability | Usually bulky, less portable | Lightweight and portable |

| Ideal For | Frequent jerky makers, professional or serious hobbyists | Casual users wanting to enhance dehydrator versatility |

Introduction to Meat Dehydration Techniques

Jerky makers provide a controlled environment specifically designed for drying meat, using consistent heat and airflow to achieve optimal dehydration. These devices help preserve meat by removing moisture efficiently, which inhibits bacterial growth and extends shelf life.

Paraflexx sheets, made from food-grade silicone, serve as non-stick surfaces inside dehydrators, preventing delicate meat slices from sticking while allowing moisture to escape. They are compatible with various dehydrators and facilitate even drying by promoting better air circulation around the meat.

What Is a Jerky Maker?

A jerky maker is a specialized dehydrator designed specifically to dry meat efficiently by circulating warm air evenly. It ensures consistent moisture removal to create safe, shelf-stable jerky.

- Purpose-built appliance - Designed exclusively for drying meat, providing optimal temperature and airflow settings.

- Even drying - Circulates heat uniformly to reduce drying time and prevent spoilage.

- User-friendly controls - Often includes presets tailored for jerky recipes, enhancing convenience.

Jerky makers provide a reliable and efficient solution for producing high-quality dried meat compared to general dehydrators or using Paraflexx sheets alone.

Overview of Paraflexx Sheets

Paraflexx sheets are silicone drying mats designed to enhance the meat drying process by preventing sticking and allowing even airflow. These sheets are heat-resistant and reusable, making them ideal for use in various dehydrators.

Unlike traditional jerky makers that require trays with specific perforations, Paraflexx sheets fit into standard dehydrator trays, offering versatility and easy cleanup. Their non-stick surface also helps maintain the texture and quality of dried meat products.

Efficiency: Jerky Maker vs Paraflexx Sheets

Jerky makers offer controlled temperature settings and uniform air circulation, resulting in faster and more consistent drying of meat compared to Paraflexx sheets. Paraflexx sheets rely on external dehydrator trays and may require longer drying times due to less efficient airflow management. For users prioritizing efficiency and optimal moisture removal, jerky makers provide a more effective drying solution than Paraflexx sheets.

Texture and Flavor Results Compared

Jerky makers typically provide uniform heat distribution, resulting in consistent texture and intensified flavor in dried meat. Paraflexx sheets, while less uniform, offer a more natural drying experience that preserves the meat's original taste and chewiness.

- Jerky Maker Texture - Produces evenly dehydrated meat with a firm, chewy consistency preferred by jerky enthusiasts.

- Paraflexx Flavor - Maintains the authentic meat flavor by allowing slower, less processed drying.

- Comparative Results - Jerky makers enhance flavor concentration through controlled heat, whereas Paraflexx sheets preserve the meat's natural moisture and texture variations.

Cleaning and Maintenance Differences

| Jerky Maker | Paraflexx Sheets |

|---|---|

| Requires thorough cleaning of drying trays and mesh screens to prevent buildup of meat residues and bacteria. Frequent disassembly needed for deep cleaning, often involving soaking and scrubbing with brushes. Stainless steel components may be dishwasher-safe, reducing cleaning effort. | Easy to clean with simple wipe-down or rinsing, as the non-stick silicone surface prevents meat from sticking. Dishwasher-safe design offers quick maintenance without the need for scrubbing or soaking. Durable material resists staining and odor retention, minimizing long-term cleaning challenges. |

Food Safety and Hygiene Factors

Jerky makers provide controlled temperature and airflow settings that ensure consistent drying, significantly reducing the risk of bacterial growth during the dehydrating process. Paraflexx sheets, designed to be non-stick and BPA-free, promote hygienic meat drying by preventing cross-contamination and facilitating easy cleaning between batches. Both tools contribute to food safety, but jerky makers offer precise environmental control critical for achieving optimal pathogen reduction in dried meat products.

Cost and Durability Comparison

Which option offers better cost efficiency and durability for dehydrating meat, Jerky Maker or Paraflexx Sheets? Jerky Maker typically requires a higher initial investment but provides long-lasting, heat-resistant components that withstand repeated use. Paraflexx Sheets are more affordable upfront but may wear out faster and need replacement sooner, impacting overall cost-effectiveness in long-term drying projects.

User Experience and Practical Tips

Jerky makers often provide consistent temperature control, ensuring evenly dried meat with minimal user intervention. Paraflexx sheets offer flexibility by allowing use in various dehydrators, making cleanup easier and preserving the mesh trays underneath.

- Temperature Consistency - Jerky makers maintain stable heat, optimizing drying times and preventing spoilage.

- Versatility - Paraflexx sheets fit multiple dehydrator models, adapting to different drying setups.

- Ease of Cleaning - Paraflexx sheets reduce mess and simplify maintenance compared to direct tray use.

Related Important Terms

Mesh Tray Dehydrator

Mesh tray dehydrators excel in evenly circulating airflow to remove moisture from meat, enhancing dehydration efficiency compared to solid surfaces. Paraflexx sheets provide a non-stick, easy-to-clean alternative that prevents small meat pieces from falling through the mesh, optimizing jerky drying without sacrificing airflow.

Nonstick Jerky Mat

Nonstick Jerky Mats provide superior convenience and cleanup when dehydrating meat compared to Paraflexx Sheets, eliminating the need for additional oils or sprays to prevent sticking. Their durable, reusable surface promotes even airflow and consistent drying, making them an essential tool for efficient jerky making in any jerky maker.

Silicone Dehydrator Liner

Silicone dehydrator liners like Paraflexx sheets provide a non-stick surface that enhances airflow and even drying, preventing small meat pieces from falling through the racks during jerky making. Unlike traditional jerky makers, Paraflexx sheets are flexible, easy to clean, and compatible with multiple dehydrator brands, optimizing meat dehydration efficiency and texture.

Airflow Optimization Layer

Jerky Maker utilizes an Airflow Optimization Layer designed to evenly distribute hot air, ensuring consistent dehydration and preventing uneven drying or spoilage. Paraflexx Sheets enhance airflow by creating a non-stick, breathable surface that promotes efficient moisture evaporation while maintaining proper air circulation around meat strips.

Stick-Free Meat Sheet

Jerky makers equipped with stick-free meat sheets such as Paraflexx sheets ensure even drying by preventing meat from sticking during dehydration, enhancing airflow and reducing cleanup time. These specialized sheets provide a non-toxic, dishwasher-safe surface designed specifically for drying jerky, making them a superior choice over traditional trays or paper.

Dual-Dry System

The Jerky Maker with its Dual-Dry System enhances airflow distribution for more consistent dehydration compared to Paraflexx Sheets, which primarily rely on static drying surfaces. This technology accelerates moisture removal, resulting in evenly dried meat with improved texture and extended shelf life.

Drip-Catch Insert

Jerky makers equipped with drip-catch inserts efficiently collect excess moisture and fat, preventing messes and improving drying conditions during meat dehydration. Paraflexx sheets, while providing a non-stick surface for drying, lack integrated drip-catch features, making jerky makers superior for drip management and consistent dehydration results.

Paraflexx Barrier

Paraflexx Barrier sheets enhance the dehydrating process by providing a non-stick, breathable surface that promotes even airflow and moisture release, preventing meat from sticking during drying. Unlike traditional jerky makers, Paraflexx sheets ensure consistent drying results and easy cleanup while maintaining optimal texture and flavor.

Meat Texture Enhancer

Jerky makers provide consistent low heat and airflow that evenly removes moisture, resulting in a tender yet firm meat texture ideal for jerky. Paraflexx sheets facilitate non-stick drying by allowing meat juices to drain away, enhancing texture by preventing sogginess and promoting uniform drying surfaces.

Jerky Maker vs Paraflexx Sheets for drying meat. Infographic

cookingdiff.com

cookingdiff.com