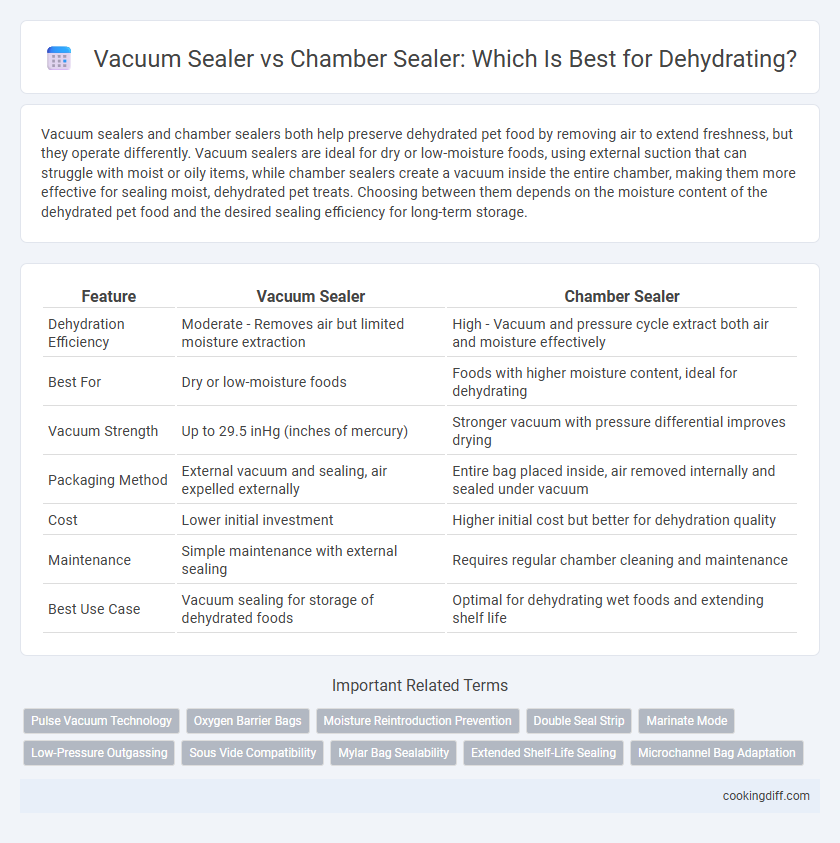

Vacuum sealers and chamber sealers both help preserve dehydrated pet food by removing air to extend freshness, but they operate differently. Vacuum sealers are ideal for dry or low-moisture foods, using external suction that can struggle with moist or oily items, while chamber sealers create a vacuum inside the entire chamber, making them more effective for sealing moist, dehydrated pet treats. Choosing between them depends on the moisture content of the dehydrated pet food and the desired sealing efficiency for long-term storage.

Table of Comparison

| Feature | Vacuum Sealer | Chamber Sealer |

|---|---|---|

| Dehydration Efficiency | Moderate - Removes air but limited moisture extraction | High - Vacuum and pressure cycle extract both air and moisture effectively |

| Best For | Dry or low-moisture foods | Foods with higher moisture content, ideal for dehydrating |

| Vacuum Strength | Up to 29.5 inHg (inches of mercury) | Stronger vacuum with pressure differential improves drying |

| Packaging Method | External vacuum and sealing, air expelled externally | Entire bag placed inside, air removed internally and sealed under vacuum |

| Cost | Lower initial investment | Higher initial cost but better for dehydration quality |

| Maintenance | Simple maintenance with external sealing | Requires regular chamber cleaning and maintenance |

| Best Use Case | Vacuum sealing for storage of dehydrated foods | Optimal for dehydrating wet foods and extending shelf life |

Introduction to Dehydrating and Vacuum Sealing

Dehydrating removes moisture from food to preserve flavor and extend shelf life. Vacuum sealing prevents air exposure, enhancing the effects of dehydration by maintaining food quality and preventing spoilage.

- Vacuum Sealer - Uses external suction to remove air from bags, best for flat or flexible items.

- Chamber Sealer - Removes air from a sealed chamber for uniform vacuum, ideal for liquids and irregularly shaped foods.

- Dehydration Efficiency - Vacuum sealing reduces oxidation and moisture reabsorption, improving overall dehydrated food preservation.

What Is a Vacuum Sealer?

| Vacuum Sealer Definition | A vacuum sealer is a device that removes air from specially designed bags or containers to create an airtight seal, significantly extending the shelf life of dehydrated foods by preventing oxidation and moisture intrusion. |

| Functionality | The vacuum sealer works by extracting air using an external pump, making it ideal for flat, flexible packaging but less effective with thicker or liquid-rich foods compared to chamber sealers. |

| Usage in Dehydrating | Vacuum sealers are commonly used for preserving dried fruits, herbs, and jerky, as removing air helps maintain flavor, texture, and nutrient retention during long-term storage. |

What Is a Chamber Sealer?

A chamber sealer is a vacuum sealing machine designed to remove air from the entire chamber, including the packaging, creating a strong vacuum ideal for dehydrating foods. It uses a sealed environment to ensure consistent pressure during the sealing process, which improves preservation and reduces oxidation.

Chamber sealers are more effective for moist or liquid-rich foods compared to vacuum sealers, making them suitable for preserving dehydrated fruits, vegetables, and jerky. Their ability to vacuum seal without crushing delicate dehydrated items makes them a preferred choice in food preservation and storage.

Vacuum Sealer vs Chamber Sealer: Key Differences

Vacuum sealers use external vacuum pumps to remove air from bags, ideal for dry or low-moisture foods during dehydrating. Chamber sealers create vacuum inside a sealed chamber, efficiently handling liquids and high-moisture foods by evacuating air uniformly. The key difference lies in chamber sealers' ability to prevent bag collapse, making them better suited for preserving dehydrated fruits and vegetables with moisture content.

Dehydrated Food Storage: Importance of Proper Sealing

Proper sealing is crucial for dehydrated food storage to prevent moisture, air, and contaminants from compromising the food's quality and shelf life. Vacuum sealers remove air around individual food packages, creating a tight seal that significantly slows oxidation and spoilage.

Chamber sealers provide a more uniform vacuum by removing air from both the package and chamber, making them ideal for storing bulk dehydrated foods or liquids. This method enhances preservation by ensuring complete air extraction and airtight sealing, which is essential for long-term storage. Using a chamber sealer can extend the shelf life of dehydrated foods by maintaining optimal freshness and preventing freezer burn or mold growth.

Pros and Cons of Using a Vacuum Sealer for Dehydrated Foods

Is a vacuum sealer effective for preserving dehydrated foods? Vacuum sealers remove air to extend shelf life, reducing oxidation and moisture exposure. However, they may crush fragile dehydrated items and are less efficient for large batches compared to chamber sealers.

Pros and Cons of Using a Chamber Sealer for Dehydrated Foods

Chamber sealers create an airtight environment by removing air both from the bag and the chamber, which helps preserve the texture and flavor of dehydrated foods more effectively than vacuum sealers. They handle liquids and powders better, preventing damage during sealing and providing a reliable seal for long-term storage. However, chamber sealers tend to be more expensive and bulkier, making them less convenient for casual or small-scale dehydrating tasks.

Cost Comparison: Vacuum Sealer vs Chamber Sealer

Vacuum sealers typically range from $50 to $200, making them a budget-friendly option for home dehydrating projects. Chamber sealers, however, start at around $1,000 and can exceed $10,000, reflecting their industrial-grade capabilities.

While vacuum sealers offer affordable initial costs, chamber sealers provide long-term savings with their superior sealing performance and durability. Investing in a chamber sealer can reduce waste and enhance preservation, justifying the higher upfront expense for commercial dehydrating operations.

Best Practices for Sealing and Storing Dehydrated Foods

Vacuum sealers and chamber sealers each offer distinct advantages for preserving dehydrated foods, with chamber sealers providing a stronger, more uniform vacuum ideal for dense or moist items. Using proper sealing techniques significantly extends shelf life and maintains the quality of dehydrated products.

- Choose the Right Sealer - Chamber sealers handle moisture better and create airtight seals that prevent spoilage, while standard vacuum sealers are suitable for dry, lightweight dehydrated foods.

- Use Oxygen Absorbers - Including oxygen absorbers in vacuum-sealed bags minimizes oxidation and enhances the longevity of dehydrated items.

- Store in Cool, Dark Places - Sealed dehydrated foods retain optimal texture and flavor when stored away from heat and light to reduce nutrient loss and prevent rancidity.

Related Important Terms

Pulse Vacuum Technology

Pulse Vacuum Technology in chamber sealers offers precise control over air removal and pressure cycles, enhancing moisture extraction during dehydrating processes compared to standard vacuum sealers. This technology minimizes product oxidation and improves shelf life by optimizing dehydration efficiency and sealing integrity for sensitive foods.

Oxygen Barrier Bags

Vacuum sealers paired with oxygen barrier bags effectively preserve moisture and flavor during dehydrating by removing air to prevent oxidation, while chamber sealers offer superior vacuum strength and uniform sealing for bulk or moist products, enhancing long-term storage quality. Oxygen barrier bags specifically enhance shelf life by blocking oxygen and moisture infiltration, making them ideal for dehydrated foods needing extended freshness.

Moisture Reintroduction Prevention

Vacuum sealers create an airtight environment that significantly reduces moisture reintroduction, but chamber sealers offer superior performance by evenly evacuating air, including moisture vapor, from the package, ensuring longer-lasting dehydration. Chamber sealers minimize risk of moisture absorption during sealing, making them more effective for preserving the texture and shelf life of dehydrated foods.

Double Seal Strip

Vacuum sealers with a double seal strip provide enhanced airtight packaging by creating two parallel seals, reducing the risk of leaks and extending the shelf life of dehydrated foods. Chamber sealers utilize this double seal technology more effectively by evenly removing air from the entire package, ensuring optimal preservation and preventing moisture reabsorption during the dehydration storage process.

Marinate Mode

Vacuum sealers with Marinate Mode use rapid pressure changes to infuse marinades efficiently, enhancing flavor penetration in dehydrated foods. Chamber sealers offer superior marination by uniformly applying vacuum and pressure around the food, creating deeper and more consistent marinade absorption for optimal dehydration results.

Low-Pressure Outgassing

Vacuum sealers create low-pressure environments that accelerate outgassing by removing air and moisture from dehydrated foods, preserving texture and flavor effectively. Chamber sealers, operating at even lower pressures, enhance outgassing efficiency, making them more suitable for moisture-sensitive products by preventing reabsorption of gases during sealing.

Sous Vide Compatibility

Vacuum sealers with external suction are generally compatible with dehydrating and sous vide cooking, effectively removing air to preserve food texture and flavor, but may struggle with liquids released during the process. Chamber sealers excel in sealing liquids and moist foods, providing airtight bags ideal for prolonged sous vide cooking and dehydration by preventing oxidation and contamination.

Mylar Bag Sealability

Vacuum sealers and chamber sealers differ significantly in Mylar bag sealability for dehydrating: chamber sealers provide a uniform, airtight seal suitable for thicker Mylar bags, preventing moisture and oxygen ingress, while vacuum sealers may struggle with consistent seals on Mylar material, especially when moisture is present. Optimizing dehydration results requires chamber sealers to maintain product quality and extend shelf life by ensuring superior package integrity.

Extended Shelf-Life Sealing

Vacuum sealers create an extended shelf-life by removing air from flexible bags, ideal for dehydrated foods with solid textures, while chamber sealers achieve a stronger, more uniform vacuum inside rigid or thicker pouches, enhancing preservation for moisture-sensitive dehydrated items. Chamber sealers are preferred for high-volume, commercial dehydrating due to superior vacuum efficiency and consistent sealing, reducing oxidation and microbial growth for longer storage times.

Vacuum sealer vs Chamber sealer for dehydrating. Infographic

cookingdiff.com

cookingdiff.com