Sheet pans offer a larger, flat surface ideal for evenly spreading pet food for dehydration, ensuring consistent airflow and drying. Stackable trays optimize vertical space, allowing for greater batch sizes in compact dehydrators but may require rotating trays for uniform drying. Choosing between them depends on batch volume and space efficiency needs.

Table of Comparison

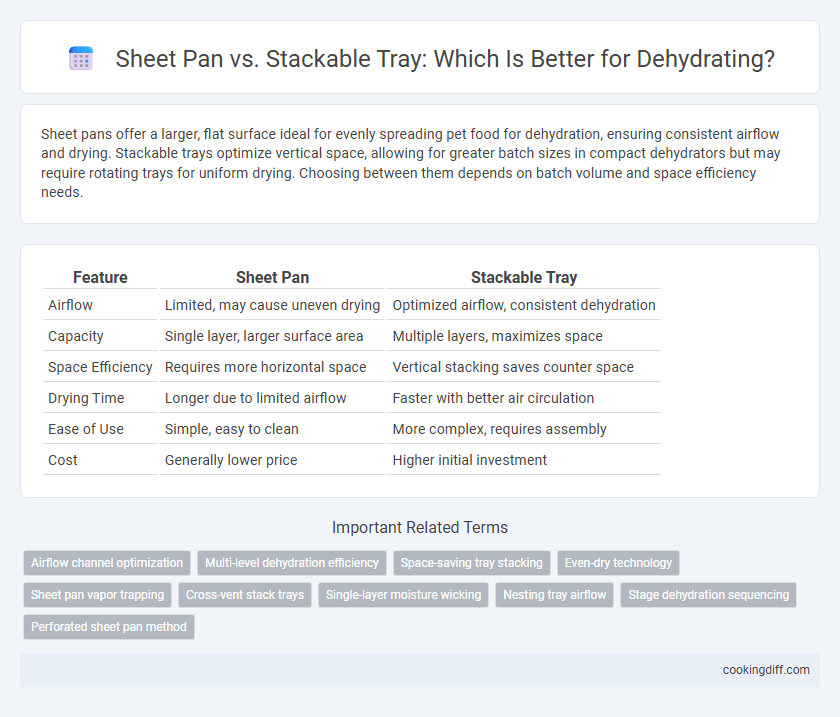

| Feature | Sheet Pan | Stackable Tray |

|---|---|---|

| Airflow | Limited, may cause uneven drying | Optimized airflow, consistent dehydration |

| Capacity | Single layer, larger surface area | Multiple layers, maximizes space |

| Space Efficiency | Requires more horizontal space | Vertical stacking saves counter space |

| Drying Time | Longer due to limited airflow | Faster with better air circulation |

| Ease of Use | Simple, easy to clean | More complex, requires assembly |

| Cost | Generally lower price | Higher initial investment |

Overview: Sheet Pan vs Stackable Tray Dehydration

Sheet pans provide a flat, open surface ideal for dehydrating large, single-layer batches of fruits, vegetables, or herbs, allowing for even air circulation and consistent drying. They are typically made of metal, which conducts heat efficiently, but require manual rotation for uniform dehydration.

Stackable trays maximize vertical space by allowing multiple layers of food to dry simultaneously within a compact footprint, making them suitable for smaller kitchens or limited dehydrator capacity. These trays often feature perforations for airflow but may result in uneven drying if not rotated regularly.

Space Efficiency and Storage Comparison

Sheet pans provide a large, flat surface ideal for dehydrating wide, thin layers but require significant countertop and storage space when not in use. Their bulky size limits efficient stacking, making them less space-efficient compared to stackable trays.

Stackable trays maximize vertical space by allowing multiple layers of food to dehydrate simultaneously in a compact footprint. These trays often nest neatly when stored, offering superior space-saving benefits over sheet pans in small kitchens.

Airflow Distribution: Which Option Performs Better?

Sheet pans provide broad, open surfaces that allow for more consistent airflow over food items, enhancing dehydration efficiency. Stackable trays, while space-saving, can restrict airflow between layers, potentially causing uneven drying.

- Sheet Pans Maximize Airflow - Their flat, open design promotes uniform air distribution across all items.

- Stackable Trays Save Space - Multiple trays fit vertically but may impede airflow between layers.

- Airflow Consistency is Crucial - Optimal dehydration results from unrestricted, even circulation around food.

Ease of Use: Loading, Unloading, and Monitoring

Sheet pans offer straightforward loading and unloading due to their flat, open design, making it easy to arrange and remove food items. Stackable trays save space but can complicate monitoring as multiple layers require lifting to check dryness.

- Sheet Pan Loading - Food is spread evenly across a single, accessible surface for quick placement.

- Stackable Tray Monitoring - Each tray must be individually lifted, slowing down inspection during dehydration.

- Sheet Pan Unloading - Simple removal of one flat layer facilitates fast transfer of dried goods.

Choosing between sheet pans and stackable trays depends on the balance between ease of use and space efficiency during the dehydration process.

Drying Times: Factors Affecting Efficiency

| Dehydration Method | Drying Time Efficiency | Key Factors Affecting Drying Time |

|---|---|---|

| Sheet Pan | Generally longer due to single-layer airflow | Limited air circulation, Larger surface area exposure, Uniform heat distribution |

| Stackable Tray | Faster drying times with optimized airflow between trays | Increased air circulation, Multiple layers of food, Consistent temperature control |

Cleaning and Maintenance Differences

Sheet pans are typically easier to clean due to their flat surfaces, which allow for quick wiping and scrubbing, often compatible with standard dishwasher cycles. Stackable trays require more detailed cleaning as food particles can become trapped between layers, necessitating thorough hand washing to prevent mold and bacteria buildup.

Sheet pans generally resist staining and odors better because of their solid metal construction, reducing long-term maintenance efforts. Stackable trays, often made of plastic or mesh, are more prone to retaining moisture and food residue, demanding meticulous drying and occasional deep cleaning to maintain hygiene. Choosing between these depends on balancing ease of cleaning with dehydration volume and airflow needs.

Capacity and Batch Size: Meeting Your Needs

Sheet pans offer a large, flat surface ideal for drying wide, thin items in single batches, allowing for easy monitoring and consistent airflow. Stackable trays maximize vertical space, enabling multiple layers of food to be dehydrated simultaneously, increasing batch size without a larger footprint. Choosing between sheet pans and stackable trays depends on whether you prioritize capacity per batch or the ability to process multiple batches efficiently.

Material Durability and Safety

Which option offers better material durability and safety for dehydration, sheet pans or stackable trays? Sheet pans are typically made from stainless steel or heavy-duty aluminum, providing excellent durability and resistance to warping at high temperatures. Stackable trays, often crafted from BPA-free plastic or food-grade materials, prioritize safety with less risk of chemical leaching but may have lower heat resistance and shorter lifespan compared to metal pans.

Versatility for Different Foods

Sheet pans offer broad surface areas ideal for drying large, flat items evenly, while stackable trays maximize vertical space for dehydrating multiple small batches simultaneously. Different configurations affect airflow and dehydration efficiency, influencing food texture and drying time.

- Sheet pans provide superior airflow - Their single-layer design allows uniform air circulation, making them perfect for large fruit slices and vegetable chips.

- Stackable trays enhance capacity - Multiple layers enable drying diverse foods at once, such as herbs, nuts, and jerky, without mixing flavors.

- Versatility depends on food type - Sheet pans suit bulk dehydration of one item, whereas stackable trays support varied foods requiring separate drying conditions.

Related Important Terms

Airflow channel optimization

Sheet pans offer a larger surface area but often suffer from restricted airflow due to limited spacing, hindering even dehydration. Stackable trays optimize airflow channels by allowing better air circulation between layers, promoting faster and more uniform drying.

Multi-level dehydration efficiency

Sheet pans provide broad surface area but limit airflow, reducing drying efficiency when stacked; stackable trays optimize multi-level dehydration by maximizing air circulation and uniform heat distribution, significantly improving moisture removal rates. Using stackable trays in food dehydrators enhances energy efficiency and preserves nutrient content through consistent drying conditions across multiple layers.

Space-saving tray stacking

Stackable trays maximize space efficiency during dehydration by allowing multiple layers of food to be dried simultaneously in a compact vertical setup, unlike sheet pans that require more horizontal surface area. This vertical stacking not only increases dehydration capacity but also improves airflow consistency, leading to more even drying results.

Even-dry technology

Sheet pans provide a large surface area that enables efficient airflow and even drying, optimizing Even-Dry technology for consistent moisture removal across the product layers. Stackable trays increase dehydration capacity but may restrict airflow, potentially compromising the uniformity that Even-Dry technology aims to achieve.

Sheet pan vapor trapping

Sheet pans often cause vapor trapping during dehydration, leading to uneven drying and extended processing times due to poor air circulation around the food. Stackable trays provide better airflow and consistent moisture removal by allowing vapors to escape freely, enhancing drying efficiency and preserving product quality.

Cross-vent stack trays

Cross-vent stack trays provide superior airflow and even dehydration compared to traditional sheet pans, enhancing moisture evaporation efficiency. Their design allows for stacked layers without compromising air circulation, making them ideal for uniform drying of herbs, fruits, and vegetables.

Single-layer moisture wicking

Sheet pans provide a single-layer surface that enhances moisture wicking by allowing even air circulation around each item, preventing sogginess during dehydration. Stackable trays, while space-efficient, often create multi-layer stacks that can trap moisture and reduce airflow, leading to uneven drying.

Nesting tray airflow

Stackable trays offer superior airflow during dehydration due to their spaced design, which allows hot air to circulate evenly around each layer, preventing moisture buildup and ensuring uniform drying. In contrast, traditional sheet pans often restrict airflow because items are placed on a single flat surface, leading to inconsistent dehydration and longer drying times.

Stage dehydration sequencing

Stackable trays optimize stage dehydration sequencing by allowing better air circulation and temperature consistency across layers, enhancing moisture removal efficiency. Sheet pans, while simpler, often limit airflow and cause uneven dehydration, making them less effective for precise sequencing control.

Sheet pan vs stackable tray for dehydration. Infographic

cookingdiff.com

cookingdiff.com