Propane dehydrators offer faster drying times and greater portability, making them ideal for outdoor or off-grid mushroom dehydration. Electric dehydrators provide consistent temperature control and energy efficiency, ensuring even drying and preserving mushroom quality over extended periods. Choosing between propane and electric depends on your need for mobility versus precision in maintaining optimal drying conditions.

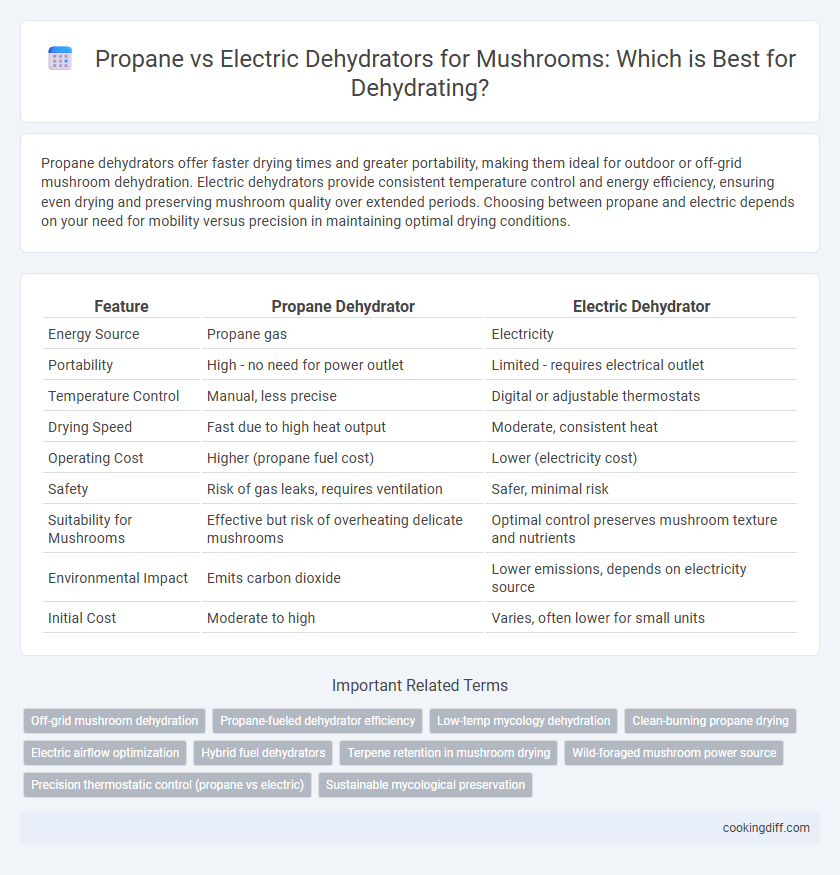

Table of Comparison

| Feature | Propane Dehydrator | Electric Dehydrator |

|---|---|---|

| Energy Source | Propane gas | Electricity |

| Portability | High - no need for power outlet | Limited - requires electrical outlet |

| Temperature Control | Manual, less precise | Digital or adjustable thermostats |

| Drying Speed | Fast due to high heat output | Moderate, consistent heat |

| Operating Cost | Higher (propane fuel cost) | Lower (electricity cost) |

| Safety | Risk of gas leaks, requires ventilation | Safer, minimal risk |

| Suitability for Mushrooms | Effective but risk of overheating delicate mushrooms | Optimal control preserves mushroom texture and nutrients |

| Environmental Impact | Emits carbon dioxide | Lower emissions, depends on electricity source |

| Initial Cost | Moderate to high | Varies, often lower for small units |

Introduction to Mushroom Dehydration Methods

Mushroom dehydration is essential for preserving flavor, nutrients, and shelf life, with propane and electric dehydrators being popular options. Each method offers distinct advantages in terms of energy efficiency, temperature control, and drying speed, influencing the quality of dried mushrooms.

- Propane Dehydrator Efficiency - Uses propane gas for heat, providing rapid drying suitable for large mushroom batches with higher energy output.

- Electric Dehydrator Control - Offers precise temperature regulation and consistent airflow, ensuring even drying and better preservation of delicate mushroom textures.

- Cost and Environmental Impact - Propane models generally incur higher fuel costs and emissions, while electric dehydrators are more eco-friendly and cost-effective over time.

How Propane Dehydrators Work for Mushrooms

Propane dehydrators for mushrooms utilize combustible propane gas to generate consistent, high heat, which efficiently removes moisture without compromising the fungi's texture or nutritional value. This heat source ensures uniform air circulation, ideal for maintaining mushroom integrity during the dehydration process.

Unlike electric dehydrators, propane models operate independently of electrical power, making them suitable for remote or off-grid locations. The precise temperature control in propane dehydrators helps prevent over-drying, preserving the mushrooms' flavor and potency effectively.

Electric Dehydrators: Features and Functionality

What are the key features and functionalities of electric dehydrators for mushrooms? Electric dehydrators offer precise temperature control and uniform airflow, ensuring consistent drying without compromising mushroom quality. Their energy-efficient design and quiet operation make them ideal for both home and commercial use.

Energy Efficiency: Propane vs. Electric Dehydrators

Propane dehydrators consume more energy due to the combustion process but offer rapid heating, making them suitable for large-scale mushroom drying. Electric dehydrators provide consistent, controlled temperatures with higher energy efficiency and lower operating costs, ideal for small to medium batches. Energy efficiency metrics show electric models use roughly 60-70% less energy compared to propane options during equivalent drying cycles.

Temperature Control and Consistency Comparison

| Dehydrator Type | Temperature Control | Consistency |

|---|---|---|

| Propane Dehydrator | Temperature control is less precise, often requiring manual adjustments and monitoring due to fluctuating heat output from propane combustion. | Heat distribution can be uneven, potentially causing inconsistent drying levels and affecting mushroom texture and quality. |

| Electric Dehydrator | Offers precise and adjustable temperature settings with built-in thermostats, allowing for accurate drying temperatures essential for mushrooms. | Provides consistent and uniform heat circulation, ensuring even dehydration and preserving mushroom flavor and nutrients. |

Drying Speed and Output Quality for Mushrooms

Propane dehydrators typically offer faster drying speeds for mushrooms due to their higher and more consistent heat output, making them ideal for large batches. Electric dehydrators provide more precise temperature control, which helps maintain the delicate texture and nutritional quality of mushrooms.

Propane units often excel in output by reducing drying time from several hours to under two, yet risk uneven dehydration if not monitored carefully. Electric dehydrators ensure even heat distribution, preserving color and flavor critical for gourmet mushrooms. Choosing between these depends on balancing drying speed needs against the desired quality and energy considerations.

Cost Analysis: Initial Investment and Running Expenses

Propane dehydrators typically require a higher initial investment due to the cost of the burner and fuel storage system compared to electric dehydrators, which often have a lower upfront price and simpler setup. Running expenses for propane models can be significant, as fuel costs fluctuate and propane consumption increases with extended use, while electric dehydrators generally incur steadier, more predictable electricity costs. When analyzing total cost of ownership for mushroom drying, electric dehydrators offer energy efficiency benefits and lower maintenance, making them more economical for frequent or long-term use.

Portability and Suitability for Off-Grid Use

Propane dehydrators offer exceptional portability and independence from electrical sources, making them ideal for off-grid mushroom drying. Electric dehydrators require a power source but provide more precise temperature control, which may be limited in remote locations.

- Propane Dehydrator Portability - Compact design and fuel canisters enable easy transport and use anywhere without electricity.

- Electric Dehydrator Suitability - Needs consistent power supply, which can restrict usage in remote or off-grid environments.

- Off-Grid Compatibility - Propane units operate independently of electrical infrastructure, supporting sustainable mushroom dehydration off the grid.

Choosing between propane and electric dehydrators depends on balancing portability with the availability of reliable power sources for effective mushroom dehydration.

Maintenance and Longevity of Each Dehydrator Type

Propane dehydrators require regular inspection of fuel lines and burners to ensure safe and efficient operation, with periodic cleaning to prevent soot buildup that can affect performance. Their mechanical components are rugged, often resulting in a longer lifespan if maintained properly, especially in settings without reliable electricity.

Electric dehydrators demand less frequent maintenance, mainly involving cleaning of heating elements and fans to avoid dust accumulation that impairs drying efficiency. The electronic components may have a shorter lifespan compared to propane models, but consistent upkeep and use within manufacturer guidelines can extend operational durability.

Related Important Terms

Off-grid mushroom dehydration

Propane dehydrators offer efficient off-grid mushroom dehydration by utilizing portable fuel without reliance on electricity, ensuring consistent heat for drying in remote locations. Electric dehydrators, while precise in temperature control, depend on stable power sources, making propane models more practical for sustainable mushroom preservation in off-grid environments.

Propane-fueled dehydrator efficiency

Propane-fueled dehydrators offer superior energy efficiency for drying mushrooms by providing consistent high heat without relying on electricity, making them ideal for off-grid or remote locations. Their rapid heat-up times and robust temperature control enhance moisture removal, resulting in faster dehydration cycles compared to electric models.

Low-temp mycology dehydration

Propane dehydrators provide consistent low temperatures ideal for preserving the delicate enzymes and nutrients in mushrooms during mycology dehydration, typically operating between 95degF and 115degF, while electric dehydrators often offer precise temperature controls but may lack uniform airflow necessary for optimal drying at low heat. Maintaining a low-temperature environment under 120degF is crucial for mycological dehydration to prevent damage to mushroom texture and potency.

Clean-burning propane drying

Propane dehydrators offer clean-burning propane drying that efficiently removes moisture from mushrooms while maintaining their flavor and nutritional content. Electric dehydrators provide precise temperature control but may lack the rapid, high-heat drying capabilities of propane models, making propane ideal for fast, uniform dehydration.

Electric airflow optimization

Electric dehydrators for mushrooms offer precise airflow optimization through adjustable fans and temperature controls, ensuring even drying and preservation of nutrient content. Propane dehydrators lack this level of air distribution control, which may result in uneven dehydration and potential quality loss.

Hybrid fuel dehydrators

Hybrid fuel dehydrators combine propane and electric power to optimize mushroom dehydration by leveraging propane's high heat output for rapid moisture removal and electric elements for precise temperature control, enhancing energy efficiency and drying consistency. These systems reduce dehydration time compared to solely electric models while maintaining delicate mushroom quality better than propane-only units, making them ideal for scalable, cost-effective mushroom preservation.

Terpene retention in mushroom drying

Propane dehydrators generate higher heat causing greater terpene loss in mushroom drying, while electric dehydrators maintain lower, consistent temperatures that better preserve delicate terpenes. Choosing an electric dehydrator enhances retention of essential flavor and aroma compounds essential for high-quality dried mushrooms.

Wild-foraged mushroom power source

Propane dehydrators offer portability and independence from electrical outlets, making them ideal for wild-foraged mushroom drying in remote locations where power is unavailable. Electric dehydrators provide consistent temperature control and energy efficiency, but require access to a reliable power source, limiting their use in outdoor or off-grid mushroom foraging scenarios.

Precision thermostatic control (propane vs electric)

Electric dehydrators offer superior precision thermostatic control with digital settings that maintain consistent temperatures ideal for drying mushrooms evenly, reducing the risk of over-drying or under-drying. Propane dehydrators rely on manual adjustments, which can result in less accurate temperature regulation and uneven dehydration.

Propane dehydrator vs Electric dehydrator for mushrooms Infographic

cookingdiff.com

cookingdiff.com