Traditional jerky racks rely on manual monitoring and consistent temperature control to dry meat evenly, often requiring frequent adjustments and longer drying times. Smart dehydrators use advanced sensors and automated settings to maintain optimal humidity and temperature, ensuring uniform drying with minimal effort. These features result in faster, more reliable jerky production while preserving flavor and texture.

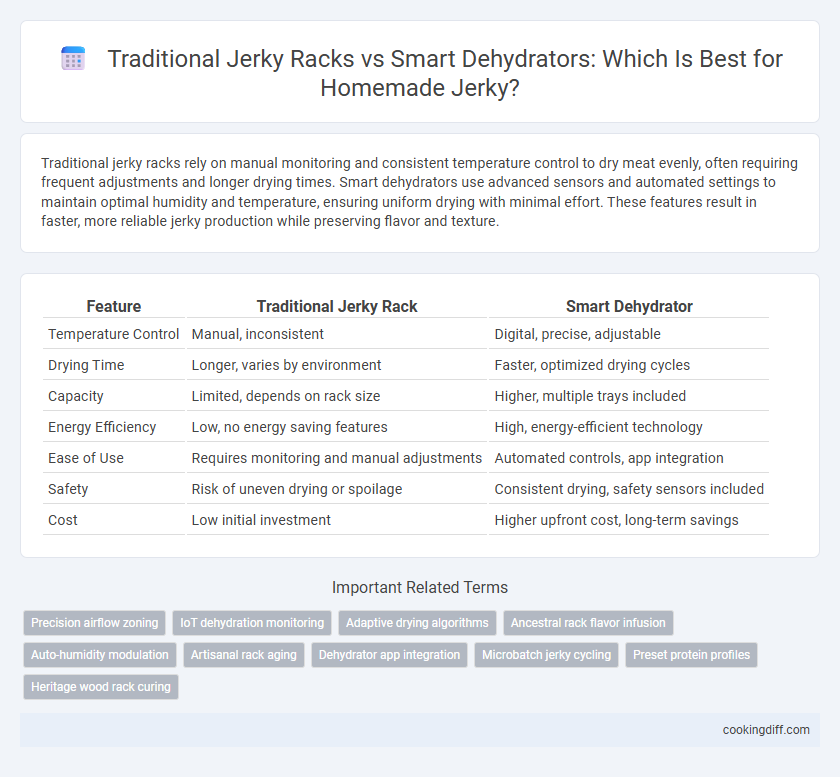

Table of Comparison

| Feature | Traditional Jerky Rack | Smart Dehydrator |

|---|---|---|

| Temperature Control | Manual, inconsistent | Digital, precise, adjustable |

| Drying Time | Longer, varies by environment | Faster, optimized drying cycles |

| Capacity | Limited, depends on rack size | Higher, multiple trays included |

| Energy Efficiency | Low, no energy saving features | High, energy-efficient technology |

| Ease of Use | Requires monitoring and manual adjustments | Automated controls, app integration |

| Safety | Risk of uneven drying or spoilage | Consistent drying, safety sensors included |

| Cost | Low initial investment | Higher upfront cost, long-term savings |

Introduction: Traditional Jerky Rack vs Smart Dehydrator

Traditional jerky racks rely on manual air circulation and consistent temperature control to dry meat, often requiring close monitoring to avoid uneven dehydration. Smart dehydrators use advanced technology with programmable settings and built-in sensors to maintain optimal temperature and humidity for perfectly dried jerky. These devices enhance convenience, reduce drying time, and improve the overall quality of homemade jerky.

Key Differences in Dehydrating Technology

Traditional jerky racks use passive airflow and rely on ambient temperature, which can result in uneven drying and longer dehydration times. Smart dehydrators incorporate digital controls and sensors to maintain consistent temperature and humidity, ensuring uniform jerky texture and safety.

While traditional racks require manual monitoring and adjustments, smart dehydrators offer programmable settings and automated cycles that optimize drying efficiency. The technology in smart dehydrators reduces the risk of over-drying or under-drying, preserving flavor and protein content better than conventional methods.

Ease of Use: Manual Racks vs Automated Controls

| Traditional Jerky Rack: Requires manual rotation and close monitoring to ensure even drying, demanding constant attention and physical effort. |

| Smart Dehydrator: Features automated temperature and timer controls that simplify the jerky-making process, reducing the need for manual adjustments. |

| Ease of Use: Smart dehydrators provide a user-friendly experience with programmable settings, whereas manual racks rely heavily on user intervention for consistent results. |

Consistency and Quality of Jerky Results

Smart dehydrators provide consistent temperature control and airflow, ensuring uniform drying and superior jerky texture. Traditional jerky racks often result in uneven dehydration due to lack of precise heat distribution, affecting overall quality.

- Smart Dehydrator Precision - Maintains optimal drying conditions for even moisture removal across all meat strips.

- Traditional Rack Variability - Heat inconsistencies cause some pieces to over-dry while others remain under-processed.

- Resulting Jerky Quality - Smart dehydrators produce tender, flavorful jerky with improved shelf life.

Choosing a smart dehydrator enhances jerky consistency and elevates product quality compared to traditional methods.

Drying Time Comparison

How does the drying time of a traditional jerky rack compare to that of a smart dehydrator? Traditional jerky racks typically require 6 to 12 hours to fully dry meat, depending on thickness and ambient temperature. Smart dehydrators utilize precise temperature and airflow controls, reducing drying time to as little as 4 to 8 hours while ensuring consistent texture and flavor.

Energy Efficiency and Cost Considerations

Traditional jerky racks consume more electricity due to inconsistent heat distribution, often requiring longer drying times and higher energy usage. Smart dehydrators optimize energy consumption with precise temperature control and timed cycles, reducing overall power costs.

Initial investment in smart dehydrators is higher compared to traditional racks, but energy savings and improved efficiency offset this over time. Traditional racks have low upfront costs but can lead to increased electricity bills and longer drying periods. Choosing a smart dehydrator offers better long-term value through energy-efficient operation and consistent jerky quality.

Batch Size and Production Volume

Traditional jerky racks typically hold a limited batch size, often around 1 to 2 pounds of meat per batch, restricting production volume for small-scale operations. These racks rely heavily on manual placement and monitoring, which can slow down the overall dehydration process and reduce efficiency.

Smart dehydrators offer larger batch capacities, frequently accommodating 3 to 5 pounds or more in a single cycle, enabling higher production output with consistent results. Automated temperature and time controls in smart dehydrators optimize drying conditions, significantly increasing throughput and reducing labor requirements.

Cleaning and Maintenance Requirements

Traditional jerky racks require extensive manual cleaning due to their open structure and multiple components that trap meat residue and juices. Smart dehydrators feature removable trays and non-stick surfaces that simplify cleaning and reduce maintenance time.

- Traditional racks trap residue - Their open design causes meat juices to accumulate, necessitating thorough scrubbing after each use.

- Smart dehydrator trays are removable - Easily detachable trays allow for quick washing and prevent buildup of bacteria.

- Non-stick surfaces reduce cleaning effort - Smart dehydrators use coatings that minimize food adhesion, leading to faster maintenance.

Flavor and Texture Outcomes

Traditional jerky racks provide a smoky, uneven drying experience that enhances the rustic flavor and produces a chewier texture. Smart dehydrators offer precise temperature control, resulting in consistent drying that preserves moisture and tenderness throughout the jerky.

- Flavor Depth - Traditional racks impart a natural, smoky flavor from open-air drying methods enhancing authenticity.

- Texture Uniformity - Smart dehydrators ensure even dehydration, preventing overly dry or undercooked spots for balanced texture.

- Moisture Retention - Controlled heat in smart dehydrators maintains optimal moisture levels, enhancing chewiness and freshness.

Related Important Terms

Precision airflow zoning

Traditional jerky racks offer basic airflow distribution that can result in uneven drying and inconsistent texture, whereas smart dehydrators utilize precision airflow zoning technology to ensure uniform heat circulation across all trays, promoting consistent moisture removal and optimal jerky quality. Enhanced control over airflow in smart dehydrators reduces drying time and minimizes the risk of over- or under-dried sections, delivering superior flavor and texture in every batch.

IoT dehydration monitoring

Traditional jerky racks rely on manual temperature and humidity adjustments, often leading to inconsistent drying results and increased risk of spoilage. Smart dehydrators equipped with IoT sensors provide real-time monitoring and precise control over dehydration parameters, ensuring optimal jerky texture, enhanced food safety, and remote operation via connected devices.

Adaptive drying algorithms

Traditional jerky racks rely on static airflow and consistent temperature settings, which can lead to uneven drying and potential spoilage. Smart dehydrators use adaptive drying algorithms that monitor humidity and temperature in real-time, optimizing airflow and drying times to produce uniformly dried jerky with improved flavor and safety.

Ancestral rack flavor infusion

Traditional jerky racks excel in ancestral flavor infusion by allowing natural air circulation that intensifies the smoky, rich taste through slow dehydration, preserving authentic textures. Smart dehydrators enhance this process with precise temperature control and humidity settings, optimizing moisture removal while maintaining the deep, infused flavors characteristic of traditional jerky.

Auto-humidity modulation

Traditional jerky racks rely on manual monitoring and adjustment of humidity levels, which can lead to inconsistent drying and variable texture. Smart dehydrators feature auto-humidity modulation sensors that precisely control moisture, ensuring evenly dried jerky with optimal tenderness and shelf life.

Artisanal rack aging

Traditional jerky racks excel in artisanal aging by allowing natural airflow and gradual moisture removal, enhancing depth of flavor and texture through slow dehydration. Smart dehydrators offer precise temperature control and consistent drying times but may lack the nuanced aging benefits that handcrafted wooden racks provide for premium jerky craftsmanship.

Dehydrator app integration

Traditional jerky racks rely on manual temperature and time settings, lacking the convenience of remote monitoring and precise control. Smart dehydrators feature app integration that enables real-time adjustments, automated drying programs, and notifications for optimal jerky texture and safety.

Microbatch jerky cycling

Traditional jerky racks provide a simple, low-cost method for dehydrating small batches of meat but often suffer from uneven airflow and inconsistent drying times, leading to variable jerky quality. Smart dehydrators with microbatch jerky cycling use precise temperature controls and timed airflow adjustments to ensure uniform dehydration, optimal texture, and enhanced flavor retention for each small batch.

Preset protein profiles

Traditional jerky racks require manual temperature and time adjustments, relying heavily on user experience for optimal drying, while smart dehydrators offer preset protein profiles calibrated for specific meats like beef, chicken, or turkey, ensuring consistent texture and safety. These intelligent settings reduce guesswork, enhancing efficiency and preserving flavor by automatically controlling humidity and drying cycles tailored to each protein type.

Traditional jerky rack vs Smart dehydrator for making jerky Infographic

cookingdiff.com

cookingdiff.com