Dehydrating preserves snacks by removing moisture through low heat over an extended period, maintaining flavor and nutrients while ensuring a chewy texture. Vacuum drying uses reduced pressure to lower the boiling point of water, accelerating drying times and retaining more delicate flavors and colors. Vacuum drying offers faster processing and better preservation of quality compared to traditional dehydrating methods in snack production.

Table of Comparison

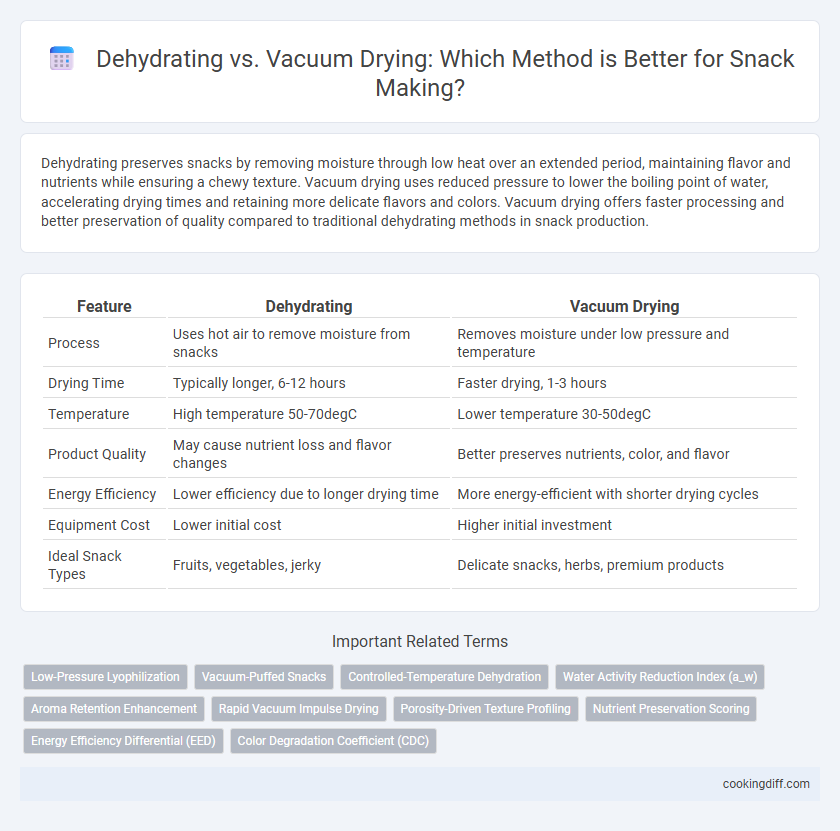

| Feature | Dehydrating | Vacuum Drying |

|---|---|---|

| Process | Uses hot air to remove moisture from snacks | Removes moisture under low pressure and temperature |

| Drying Time | Typically longer, 6-12 hours | Faster drying, 1-3 hours |

| Temperature | High temperature 50-70degC | Lower temperature 30-50degC |

| Product Quality | May cause nutrient loss and flavor changes | Better preserves nutrients, color, and flavor |

| Energy Efficiency | Lower efficiency due to longer drying time | More energy-efficient with shorter drying cycles |

| Equipment Cost | Lower initial cost | Higher initial investment |

| Ideal Snack Types | Fruits, vegetables, jerky | Delicate snacks, herbs, premium products |

Introduction to Snack Preservation Techniques

Dehydrating and vacuum drying are key snack preservation techniques that extend shelf life by removing moisture. Each method influences texture, flavor, and nutrient retention differently, making selection critical for product quality.

- Dehydrating - Uses warm air to evaporate moisture, preserving flavor and nutrients but may cause texture hardening.

- Vacuum Drying - Removes moisture under low pressure, enhancing retention of heat-sensitive nutrients and maintaining a softer texture.

- Application in Snacks - Choosing between methods depends on desired snack characteristics, shelf stability, and processing cost.

Understanding Dehydrating: Principles and Process

What are the core principles behind dehydrating in snack making? Dehydrating removes moisture by applying low heat and airflow, preserving nutrients and texture. This process slows microbial growth, ensuring longer shelf life while maintaining flavor integrity.

Vacuum Drying Explained: How It Works

Vacuum drying removes moisture by lowering the pressure, which decreases the boiling point of water, allowing snacks to dry at lower temperatures. This gentle process preserves flavor, color, and nutrients better than traditional dehydrating methods.

In vacuum drying, snacks are placed in a sealed chamber where pressure is reduced, accelerating water evaporation without heat damage. This method is ideal for delicate snacks that require maintaining texture and nutritional integrity during drying.

Key Differences Between Dehydrating and Vacuum Drying

Dehydrating and vacuum drying are both methods used to remove moisture from snacks but differ significantly in technique and impact on product quality. Dehydrating typically uses hot air to evaporate water, while vacuum drying removes moisture under reduced pressure to preserve flavor and nutrients.

- Temperature Control - Dehydrating uses higher temperatures that can affect texture, whereas vacuum drying operates at lower temperatures to maintain product integrity.

- Drying Speed - Vacuum drying is generally faster due to the reduced pressure accelerating moisture removal.

- Flavor Preservation - Vacuum drying better preserves natural flavors and nutrients compared to traditional dehydrating methods.

Choosing between dehydrating and vacuum drying depends on the desired snack quality and production efficiency.

Impact on Nutrient Retention in Snacks

| Dehydrating | Uses low to moderate heat to remove moisture, preserving vitamins such as A and C moderately well, but may cause some nutrient degradation over extended drying times. |

| Vacuum Drying | Operates under reduced pressure and lower temperatures, significantly enhancing nutrient retention, particularly antioxidants and heat-sensitive vitamins, by minimizing oxidation and thermal damage. |

| Impact on Nutrient Retention | Vacuum drying maintains higher levels of essential nutrients and bioactive compounds in snacks compared to traditional dehydrating methods, resulting in healthier, more nutrient-dense products. |

Flavor and Texture: What to Expect from Each Method

Dehydrating snacks typically retains more of the original texture but may slightly alter flavor due to longer exposure to heat. Vacuum drying preserves flavor intensity better by reducing oxidation but can result in a more compact texture.

- Dehydrating enhances crispiness - Slow moisture removal helps maintain a crunchy texture ideal for chips and fruit slices.

- Vacuum drying intensifies natural flavors - Lower temperature drying reduces flavor loss from heat degradation.

- Texture differences arise from drying environment - Dehydrating creates airy snacks, while vacuum drying produces denser, chewier products.

Energy Efficiency and Equipment Costs Compared

Dehydrating snacks generally consumes more energy compared to vacuum drying due to longer drying times and higher temperature requirements. Vacuum drying equipment involves higher upfront costs but offers significant energy savings through reduced drying times and lower temperature operation. Choosing vacuum drying can lead to long-term cost benefits despite initial investment, making it more energy-efficient and economically viable for large-scale snack production.

Shelf Life and Storage Considerations

Dehydrating reduces moisture content to inhibit microbial growth, extending snack shelf life up to several months when stored in airtight containers at room temperature. Vacuum drying further removes air and moisture, significantly enhancing shelf stability by preventing oxidation and spoilage, potentially doubling shelf life compared to traditional dehydrating methods.

Dehydrated snacks require cool, dry storage environments to maintain quality, whereas vacuum-dried snacks benefit from vacuum-sealed packaging that limits exposure to humidity and oxygen. Proper storage is critical for both methods, but vacuum drying offers superior protection against environmental factors, making it ideal for long-term snack preservation.

Best Foods for Dehydrating vs. Vacuum Drying

Dehydrating is ideal for fruits like apples, bananas, and berries, as it preserves flavor and nutrients through slow moisture removal. Vacuum drying suits delicate snacks such as herbs, nuts, and spicy seasonings, preventing oxidation and maintaining aroma by drying under low pressure at lower temperatures. Both methods optimize shelf life, but dehydrating excels with high-sugar fruits while vacuum drying benefits heat-sensitive or oil-rich foods.

Related Important Terms

Low-Pressure Lyophilization

Low-pressure lyophilization preserves snack texture and nutrients more effectively than traditional dehydrating methods by freezing food and removing moisture under vacuum, ensuring minimal heat damage. This vacuum drying technique maintains flavor integrity and extends shelf life, making it superior for high-quality snack production.

Vacuum-Puffed Snacks

Vacuum drying preserves nutrients and texture more effectively by removing moisture under low pressure, resulting in vacuum-puffed snacks with a crisp, porous structure and enhanced flavor retention. In contrast, traditional dehydrating often leads to denser, less crunchy snacks due to prolonged exposure to heat and oxygen.

Controlled-Temperature Dehydration

Controlled-temperature dehydration uses precise heat settings to remove moisture from snacks, preserving flavor and nutritional content more effectively than vacuum drying. This method optimizes texture and shelf life by maintaining consistent temperatures, reducing the risk of overheating or under-drying common in vacuum drying processes.

Water Activity Reduction Index (a_w)

Dehydrating reduces the Water Activity Reduction Index (a_w) by removing moisture through heat and air circulation, effectively lowering a_w to inhibit microbial growth in snacks. Vacuum drying achieves a more significant decrease in a_w at lower temperatures by evaporating water under reduced pressure, preserving sensory qualities while maintaining shelf stability.

Aroma Retention Enhancement

Dehydrating preserves the natural flavors and aromas of snacks through gentle heat and controlled airflow, minimizing aroma loss during the drying process. Vacuum drying enhances aroma retention further by reducing oxidation and evaporation rates, maintaining the snack's original fragrance more effectively than conventional dehydrating methods.

Rapid Vacuum Impulse Drying

Rapid Vacuum Impulse Drying accelerates moisture removal by combining vacuum pressure with controlled heat pulses, preserving snack texture and nutritional value more effectively than traditional dehydrating. This method reduces drying time while preventing oxidation and shrinkage, resulting in higher quality, shelf-stable snacks.

Porosity-Driven Texture Profiling

Dehydrating preserves snack porosity by slowly removing moisture, resulting in a crisp, airy texture critical for consumer appeal. Vacuum drying accelerates moisture removal under reduced pressure, enhancing porosity retention while preventing structural collapse, thus optimizing texture profiling for high-quality snacks.

Nutrient Preservation Scoring

Dehydrating preserves nutrients by gently removing moisture at low temperatures, scoring higher in maintaining vitamins and antioxidants compared to vacuum drying, which may cause nutrient loss due to heat exposure despite faster drying times. Nutrient preservation scoring favors dehydrating methods that optimize enzymatic retention and reduce oxidation, crucial for maintaining snack quality and health benefits.

Energy Efficiency Differential (EED)

Dehydrating typically consumes more energy due to longer drying times and higher heat requirements, whereas vacuum drying offers superior Energy Efficiency Differential (EED) by operating at lower temperatures and reduced drying durations, significantly minimizing energy consumption. The EED advantage in vacuum drying results in cost savings and enhanced sustainability for snack production processes.

Dehydrating vs Vacuum Drying for snack making. Infographic

cookingdiff.com

cookingdiff.com