Fan-only ovens circulate hot air to remove moisture from pet treats but can cause uneven drying and potential nutrient loss due to higher temperatures. Low-temperature dehydrators maintain consistent, gentle heat ideal for preserving nutrients and ensuring uniform dehydration of pet foods. Choosing a low-temperature dehydrator results in safer, more nutritious, and better-textured homemade pet treats.

Table of Comparison

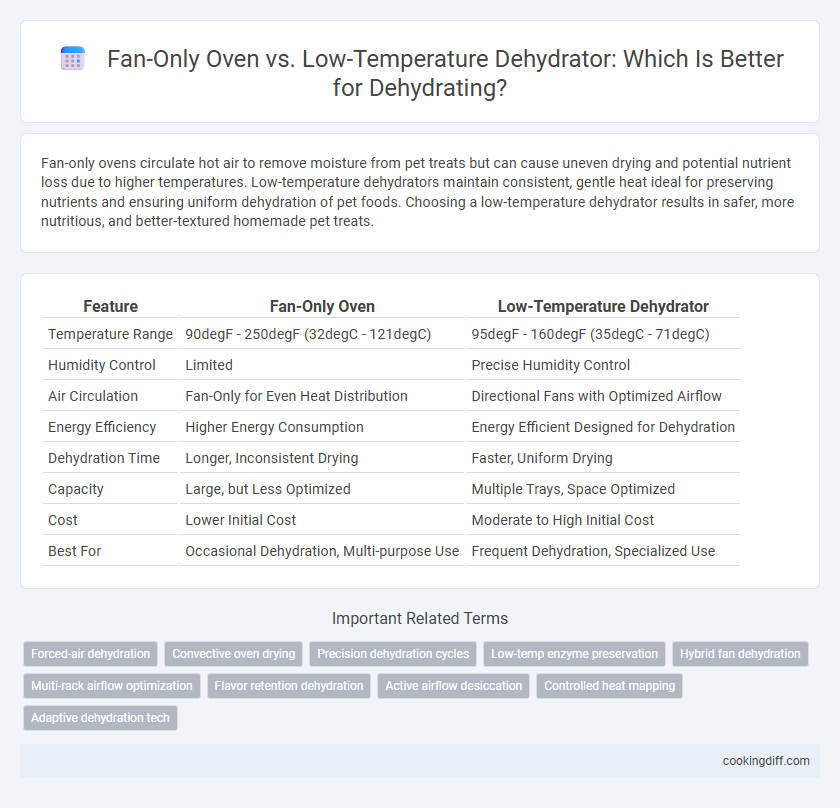

| Feature | Fan-Only Oven | Low-Temperature Dehydrator |

|---|---|---|

| Temperature Range | 90degF - 250degF (32degC - 121degC) | 95degF - 160degF (35degC - 71degC) |

| Humidity Control | Limited | Precise Humidity Control |

| Air Circulation | Fan-Only for Even Heat Distribution | Directional Fans with Optimized Airflow |

| Energy Efficiency | Higher Energy Consumption | Energy Efficient Designed for Dehydration |

| Dehydration Time | Longer, Inconsistent Drying | Faster, Uniform Drying |

| Capacity | Large, but Less Optimized | Multiple Trays, Space Optimized |

| Cost | Lower Initial Cost | Moderate to High Initial Cost |

| Best For | Occasional Dehydration, Multi-purpose Use | Frequent Dehydration, Specialized Use |

Introduction: Dehydrating Foods at Home

Is a fan-only oven or a low-temperature dehydrator more effective for dehydrating foods at home? Fan-only ovens provide consistent heat distribution ideal for drying fruits and vegetables quickly. Low-temperature dehydrators offer precise temperature control and energy efficiency, preserving nutrients and flavors better during the dehydration process.

Overview: Fan-Only Oven vs Low-Temperature Dehydrator

Fan-only ovens circulate hot air to speed up moisture evaporation, but they often operate at higher temperatures that can affect nutrient retention in foods. Low-temperature dehydrators maintain consistent, gentle heat that preserves enzymes and flavor more effectively during the drying process.

Fan-only ovens are more versatile for general cooking but may lack precise temperature control, making them less ideal for delicate dehydration tasks. Low-temperature dehydrators provide regulated airflow and temperature settings from 95degF to 160degF, optimizing dehydration for fruits, vegetables, and herbs. Choosing the right equipment depends on the desired outcome, processing time, and the specific characteristics of the food being dehydrated.

Temperature Control Precision

Fan-only ovens often lack precise temperature control, leading to inconsistent dehydration results and potential over-drying or under-drying of foods. Low-temperature dehydrators provide accurate thermostats that maintain stable temperatures typically between 95degF and 160degF, ensuring optimal moisture removal without damaging nutrients. Precise temperature control in dehydrators enhances food preservation quality and extends shelf life compared to the broader temperature fluctuations in fan-only ovens.

Airflow and Even Drying

Fan-only ovens utilize a single fan that circulates hot air unevenly, which can result in inconsistent drying and requires frequent tray rotation. Low-temperature dehydrators are designed with multiple fans or a horizontal airflow system to ensure uniform air distribution, promoting even drying and better moisture removal.

- Fan-only oven airflow - Primarily uses one fan that may cause uneven heat dispersion across food trays.

- Dehydrator airflow - Employs horizontal or multi-fan airflow to maintain consistent temperature and moisture levels.

- Drying uniformity - Dehydrators provide more consistent and even drying due to optimized air circulation.

Energy Efficiency Comparison

Fan-only ovens consume significantly more electricity, typically ranging from 1,200 to 2,500 watts, making them less energy-efficient for prolonged dehydrating tasks. Low-temperature dehydrators operate at lower wattages between 250 to 600 watts, optimizing energy use over extended drying periods while maintaining consistent temperatures.

Dehydrators are designed for continuous airflow and precise heat distribution, reducing energy waste compared to fan-only ovens that cycle frequently to maintain temperature. Energy efficiency in dehydrators contributes to lower utility costs and is more environmentally sustainable during frequent or bulk food dehydration.

Capacity and Batch Size

Fan-only ovens typically offer larger capacities, allowing for bigger batch sizes ideal for drying large quantities of food simultaneously. Low-temperature dehydrators, however, provide more consistent airflow and temperature control suited for delicate dehydration tasks but often have smaller trays, limiting the batch size. For extensive food preservation projects, fan-only ovens can be more efficient, while low-temperature dehydrators excel in precision for smaller, nutrient-sensitive batches.

Food Quality and Texture Outcomes

Fan-only ovens often circulate air at higher temperatures, which can cause uneven drying and tougher textures in dehydrated foods. Low-temperature dehydrators maintain consistent heat and airflow, preserving the natural texture and flavor more effectively.

- Fan-only oven results - Can produce uneven moisture removal, leading to chewy or brittle textures.

- Low-temperature dehydrator benefits - Ensures gentle, uniform dehydration that maintains original food integrity.

- Texture preservation - Dehydrators retain better color, taste, and nutrient density compared to fan-only ovens.

Ease of Use and Maintenance

Fan-only ovens offer straightforward operation with familiar controls, making them accessible for beginners. Low-temperature dehydrators require precise temperature settings but often include preset modes that simplify the process.

- Fan-only oven setup - Typically involves manual temperature adjustment and monitoring, which can be less precise for dehydration.

- Dehydrator cleaning - Dehydrators often have removable trays and non-stick surfaces, facilitating easier maintenance compared to ovens.

- Energy efficiency - Low-temperature dehydrators use less energy due to optimized airflow and consistent temperatures, reducing operational complexity.

Low-temperature dehydrators generally provide better ease of use and simpler maintenance for sustained dehydrating tasks.

Cost Considerations

Fan-only ovens generally have a lower upfront cost compared to specialized low-temperature dehydrators, making them an attractive option for budget-conscious users. However, these ovens may consume more energy due to less efficient temperature control, potentially increasing long-term expenses.

Low-temperature dehydrators typically involve higher initial investment but offer precise temperature regulation that enhances energy efficiency and product quality. Considering the balance between initial cost and operational savings is essential when choosing the most cost-effective dehydration method.

Related Important Terms

Forced-air dehydration

Fan-only ovens use a heating element combined with a built-in fan to circulate warm air, enabling efficient forced-air dehydration by promoting even moisture removal from food at consistent low temperatures. Low-temperature dehydrators are specifically designed for precise temperature control and optimal airflow, resulting in more uniform dehydration with minimal nutrient loss compared to fan-only ovens.

Convective oven drying

Fan-only ovens utilize convective heat transfer to circulate hot air rapidly, accelerating moisture removal during dehydration, but often lack precise temperature control needed for delicate foods. Low-temperature dehydrators provide consistent, gentle airflow and stable heat around 40-70degC, optimizing enzymatic preservation and nutrient retention through controlled convective drying processes.

Precision dehydration cycles

Fan-only ovens offer less precise dehydration cycles due to inconsistent airflow and uneven heat distribution, often resulting in unevenly dried products. Low-temperature dehydrators are designed with controlled air circulation and exact temperature settings, ensuring uniform moisture removal and optimal preservation of nutrients during dehydration.

Low-temp enzyme preservation

Low-temperature dehydrators maintain optimal enzyme activity by drying food below 115degF (46degC), preserving nutritional value and flavor more effectively than fan-only ovens, which typically operate at higher temperatures. This precise temperature control minimizes nutrient degradation, making low-temp dehydrators ideal for enzyme preservation during dehydration.

Hybrid fan dehydration

Hybrid fan dehydration combines the consistent airflow of a fan-only oven with the precise temperature control of a low-temperature dehydrator, optimizing moisture removal and preserving nutrients effectively. This method accelerates drying times while maintaining food texture and flavor, outperforming traditional single-method dehydrating appliances.

Multi-rack airflow optimization

Fan-only ovens typically lack precise multi-rack airflow optimization, which can result in uneven dehydration and longer drying times. Low-temperature dehydrators are engineered with specialized fans and venting systems that ensure consistent airflow across multiple racks, promoting uniform drying and preserving food quality efficiently.

Flavor retention dehydration

Fan-only ovens typically use higher temperatures and airflow that can cause uneven drying and a loss of delicate flavors in herbs and fruits, whereas low-temperature dehydrators employ controlled heat and consistent air circulation to preserve essential oils and natural taste compounds more effectively. Maintaining dehydration temperatures between 95degF and 115degF in a dedicated dehydrator maximizes flavor retention by preventing nutrient degradation and volatilization of aromatic compounds.

Active airflow desiccation

Fan-only ovens rely on active airflow desiccation by circulating hot air to rapidly remove moisture, which can result in uneven drying and potential nutrient loss due to higher temperatures. Low-temperature dehydrators use controlled, consistent active airflow at lower temperatures, ensuring uniform drying while preserving enzymes and nutritional content for optimal dehydration results.

Controlled heat mapping

A fan-only oven provides uneven heat distribution and inconsistent airflow, often causing fluctuating temperatures that compromise the dehydration process, whereas a low-temperature dehydrator utilizes precise heat mapping and uniform airflow to maintain consistent temperatures ideal for effective moisture removal. Controlled heat mapping in dehydrators ensures even drying, preserves nutrient content, and prevents over-drying or bacterial growth, making it superior for dehydration accuracy and food safety.

Fan-only oven vs Low-temperature dehydrator for dehydrating. Infographic

cookingdiff.com

cookingdiff.com