Plastic dehydrator trays are lightweight and affordable but may harbor bacteria due to scratches and are prone to warping at high temperatures, potentially compromising food safety. Stainless steel trays offer superior durability and resistance to corrosion, making them more hygienic and easier to sanitize, which reduces the risk of contamination during dehydration. Choosing stainless steel trays enhances long-term food safety by minimizing exposure to harmful substances and microbial growth.

Table of Comparison

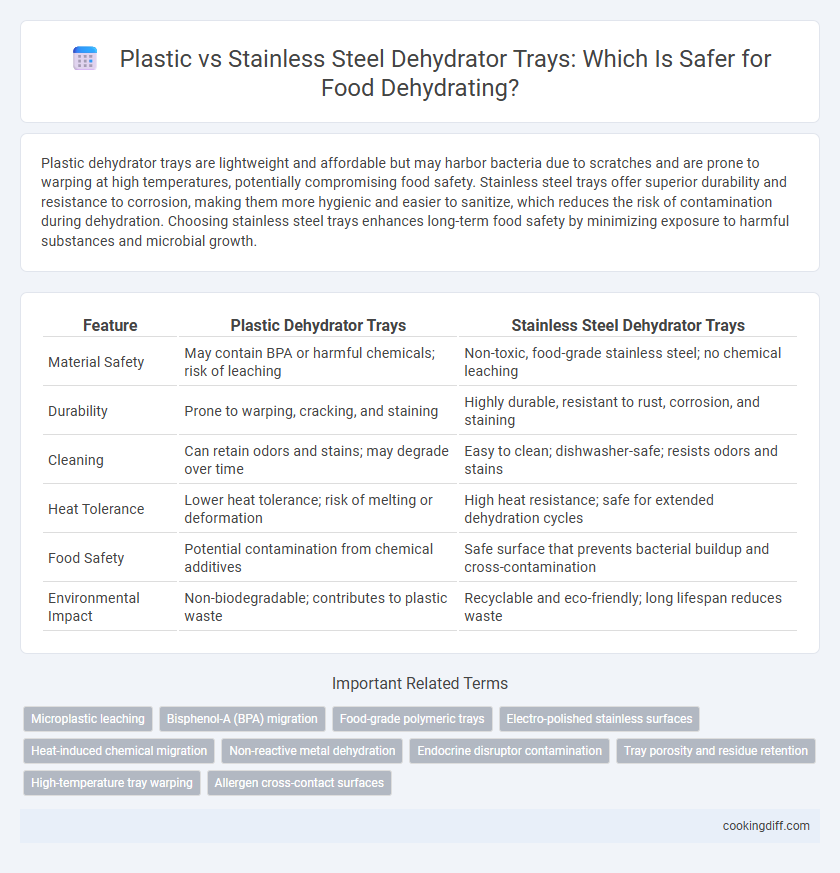

| Feature | Plastic Dehydrator Trays | Stainless Steel Dehydrator Trays |

|---|---|---|

| Material Safety | May contain BPA or harmful chemicals; risk of leaching | Non-toxic, food-grade stainless steel; no chemical leaching |

| Durability | Prone to warping, cracking, and staining | Highly durable, resistant to rust, corrosion, and staining |

| Cleaning | Can retain odors and stains; may degrade over time | Easy to clean; dishwasher-safe; resists odors and stains |

| Heat Tolerance | Lower heat tolerance; risk of melting or deformation | High heat resistance; safe for extended dehydration cycles |

| Food Safety | Potential contamination from chemical additives | Safe surface that prevents bacterial buildup and cross-contamination |

| Environmental Impact | Non-biodegradable; contributes to plastic waste | Recyclable and eco-friendly; long lifespan reduces waste |

Introduction: Importance of Tray Material in Food Dehydration

Tray material plays a critical role in maintaining food safety during dehydration by influencing contamination risk and durability. Choosing the right material ensures efficient dehydration and preserves the nutritional quality of food.

- Plastic trays are lightweight and affordable - they can be prone to warping and may harbor bacteria if scratched or damaged over time.

- Stainless steel trays are highly durable and non-porous - they resist corrosion and are easier to sanitize, reducing microbial contamination risks.

- Material impacts heat distribution - stainless steel typically provides more even drying compared to plastic, improving food safety and quality.

Plastic vs Stainless Steel: Overview of Dehydrator Trays

Plastic dehydrator trays are lightweight and often more affordable, but they can retain odors and stains over time, raising concerns about long-term food safety. Stainless steel trays offer superior durability, resist corrosion, and do not absorb food particles, making them a safer option for repeated use in food dehydration.

Stainless steel trays are easy to clean and do not leach chemicals, which is crucial in maintaining food quality during dehydration processes. Plastic trays may release harmful substances when exposed to high heat, making stainless steel the preferred choice for health-conscious users.

Material Composition and Food Contact Safety

Plastic dehydrator trays, typically made from BPA-free polypropylene, offer lightweight convenience but may risk chemical leaching when exposed to high temperatures during dehydration. Stainless steel trays, composed of food-grade 304 or 316 stainless steel, provide superior resistance to corrosion and eliminate concerns of harmful substance migration.

Food contact safety is enhanced with stainless steel due to its non-porous surface that resists bacterial contamination and is easier to sanitize. While plastic trays can be dishwasher-safe, repeated exposure to heat and acids from foods increases degradation risk, making stainless steel a more durable, hygienic choice.

Heat Resistance: Performance at High Dehydration Temperatures

Stainless steel trays exhibit superior heat resistance during high-temperature dehydration, maintaining structural integrity without warping or releasing harmful substances. Plastic dehydrator trays may soften or degrade when exposed to prolonged heat, posing potential food safety risks from chemical leaching. Selecting stainless steel trays ensures consistent performance and safer food preservation at elevated drying temperatures.

Chemical Leaching Risks: BPA and Other Contaminants

Plastic dehydrator trays may pose chemical leaching risks, releasing BPA and other contaminants into food, especially when exposed to heat. Stainless steel trays offer a safer alternative by being non-reactive and free from harmful chemicals that can compromise food safety.

- BPA Leaching - Plastic trays can contain BPA, which may leach into food during dehydration, posing health concerns.

- Heat Exposure - Elevated temperatures during dehydration increase the likelihood of chemical contaminants leaching from plastic trays.

- Non-Toxic Material - Stainless steel trays resist chemical leaching and maintain food purity regardless of temperature.

Choosing stainless steel trays reduces chemical contamination risks and ensures safer dehydrated food.

Durability and Longevity: Plastic vs Stainless Steel Trays

| Material | Durability | Longevity | Food Safety Impact |

| Plastic Dehydrator Trays | Moderate resistance to cracking and warping but prone to scratches and staining over time. | Typically lasts 1-3 years depending on usage and cleaning methods. | Risk of microplastic contamination from wear and potential chemical leaching when exposed to high heat. |

| Stainless Steel Trays | Highly durable with strong resistance to rust, corrosion, and physical damage. | Can last over 10 years with proper care and maintenance. | Non-reactive surface ensures no chemical leaching or contamination, promoting safer food dehydration. |

Cleaning and Sanitization: Hygiene Implications

Stainless steel trays offer superior cleaning and sanitization benefits compared to plastic dehydrator trays due to their non-porous surface, which resists bacterial buildup and prevents food residue retention. Plastic trays can develop scratches and grooves over time, creating habitats for harmful microbes and complicating thorough cleaning processes. Maintaining food safety during dehydration is more effectively ensured with stainless steel trays, which withstand rigorous sanitization methods without degrading.

Impact on Food Taste and Odor

How do plastic dehydrator trays compare to stainless steel trays in terms of impact on food taste and odor? Plastic trays can sometimes retain odors or impart subtle flavors to dehydrated foods due to their porous nature and potential chemical interactions. Stainless steel trays are non-reactive and resistant to odor absorption, ensuring that the natural taste and aroma of the food remain unaltered during dehydration.

Regulatory Standards for Food-Grade Materials

Plastic dehydrator trays must comply with FDA regulations, specifically 21 CFR 177.1520, ensuring they are made from food-grade, non-toxic materials safe for prolonged contact with food. Stainless steel trays typically meet USDA and FDA standards for food safety due to their non-reactive, durable surfaces that resist contamination.

Regulatory standards require plastic trays to be free from BPA and phthalates to prevent chemical leaching when drying foods at low temperatures. Stainless steel trays, often classified under 304 or 316 grade, provide corrosion resistance and can withstand high temperatures without degrading. These certifications ensure both materials are suitable, but stainless steel generally offers superior compliance for long-term food safety in dehydrating applications.

Related Important Terms

Microplastic leaching

Stainless steel trays are preferred over plastic dehydrator trays due to the risk of microplastic leaching, which can contaminate food and pose health hazards. Unlike plastic, stainless steel is non-porous and resistant to heat, ensuring safer, toxin-free dehydration of fruits, vegetables, and herbs.

Bisphenol-A (BPA) migration

Plastic dehydrator trays may pose a risk of Bisphenol-A (BPA) migration into food, especially when exposed to heat during dehydration, compromising food safety. Stainless steel trays offer a safer alternative by being BPA-free and resistant to chemical leaching, ensuring contaminant-free drying of foods.

Food-grade polymeric trays

Food-grade polymeric trays offer superior food safety in plastic dehydrators due to their non-toxic, BPA-free composition and resistance to microbial contamination, unlike some stainless steel trays that may corrode or leach metals over time. These polymeric trays provide consistent, even drying while maintaining hygienic standards crucial for preserving nutrient integrity and preventing cross-contamination during dehydration.

Electro-polished stainless surfaces

Electro-polished stainless steel trays offer superior resistance to corrosion and bacterial contamination compared to plastic dehydrator trays, ensuring safer food dehydration. Their smooth, impervious surfaces prevent microbial growth and are easier to clean, making them a more hygienic option for preserving food quality.

Heat-induced chemical migration

Stainless steel trays exhibit superior resistance to heat-induced chemical migration compared to plastic dehydrator trays, minimizing the risk of harmful contaminants leaching into food during dehydration. High temperatures used in food dehydration accelerate chemical migration in plastic trays, potentially releasing toxins, whereas stainless steel remains inert and food-safe under these conditions.

Non-reactive metal dehydration

Stainless steel trays provide a non-reactive surface that prevents chemical leaching and maintains food safety during dehydration, unlike some plastic dehydrator trays which may release harmful substances when heated. Choosing stainless steel ensures durable, hygienic drying conditions ideal for preserving nutrient integrity in dehydrated foods.

Endocrine disruptor contamination

Plastic dehydrator trays may leach endocrine-disrupting chemicals such as BPA and phthalates into food during dehydration, posing potential health risks. Stainless steel trays, being non-reactive and free from harmful additives, offer a safer option for preserving food without contaminant migration.

Tray porosity and residue retention

Plastic dehydrator trays often have porous surfaces that can trap food particles and moisture, increasing the risk of bacterial growth and residue buildup over time; stainless steel trays feature non-porous, smooth surfaces that resist residue retention and are easier to sanitize, enhancing overall food safety. The durability and corrosion resistance of stainless steel also prevent microbial contamination, making them a more hygienic choice for long-term food dehydration.

High-temperature tray warping

Plastic dehydrator trays are prone to warping at high temperatures, which can compromise food safety by harboring bacteria in warped crevices. Stainless steel trays resist warping even under prolonged high heat, providing a more durable and hygienic surface for dehydrating foods.

Plastic dehydrator trays vs Stainless steel trays for food safety. Infographic

cookingdiff.com

cookingdiff.com