Netting bags provide improved air circulation around food compared to air flow mesh trays, allowing for faster and more even dehydration of pet treats. The flexible mesh design of netting bags ensures better exposure to heat and airflow, reducing drying time and preventing moisture retention. While air flow mesh trays offer stability and ease of stacking, netting bags excel in optimizing airflow for consistent dehydration results.

Table of Comparison

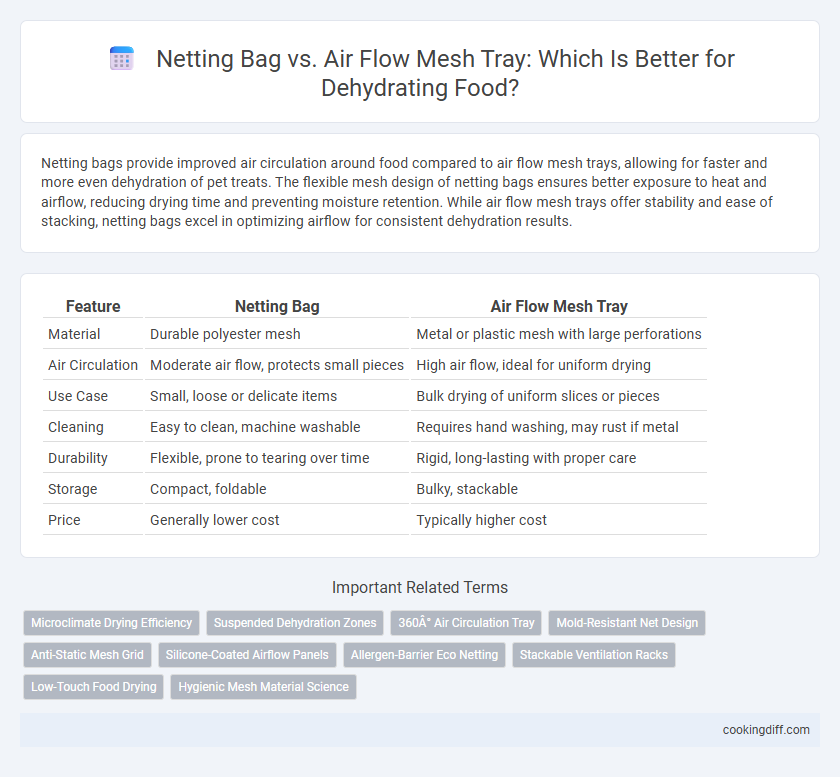

| Feature | Netting Bag | Air Flow Mesh Tray |

|---|---|---|

| Material | Durable polyester mesh | Metal or plastic mesh with large perforations |

| Air Circulation | Moderate air flow, protects small pieces | High air flow, ideal for uniform drying |

| Use Case | Small, loose or delicate items | Bulk drying of uniform slices or pieces |

| Cleaning | Easy to clean, machine washable | Requires hand washing, may rust if metal |

| Durability | Flexible, prone to tearing over time | Rigid, long-lasting with proper care |

| Storage | Compact, foldable | Bulky, stackable |

| Price | Generally lower cost | Typically higher cost |

Introduction to Dehydrating: Netting Bags vs Air Flow Mesh Trays

Dehydrating food requires effective airflow and moisture control to preserve texture and flavor. Netting bags and air flow mesh trays serve distinct roles in optimizing these conditions during the drying process.

- Netting Bags - Protect small or delicate items from falling through while allowing air circulation.

- Air Flow Mesh Trays - Provide maximum exposure to circulating air for even dehydration of larger pieces.

- Material Composition - Mesh trays are usually rigid for stability, whereas netting bags are flexible to fit various shapes.

Choosing the right method depends on the type and size of food being dehydrated for optimal results.

Material Differences: Netting Bags and Mesh Trays

Netting bags are typically made from fine, food-grade nylon or polyester designed to hold small fruit pieces or herbs securely while allowing moisture to escape effectively during dehydration. Mesh trays commonly use food-safe plastic or stainless steel wire, providing a rigid structure with larger holes for optimal air circulation.

Netting bags offer flexibility, making them ideal for drying delicate and irregularly shaped foods that might fall through standard mesh trays. Mesh trays facilitate even airflow with durable surfaces that are easy to clean and reuse, supporting higher-capacity dehydrating processes.

Air Circulation Efficiency Compared

Air flow mesh trays provide superior air circulation efficiency compared to netting bags, allowing hot air to evenly surround food items for consistent dehydration. The open structure of mesh trays facilitates faster moisture removal and reduces drying time by promoting optimal airflow. Netting bags may restrict airflow due to their denser material, leading to uneven drying and longer dehydration periods.

Drying Speed: Which Method Wins?

Air flow mesh trays significantly enhance drying speed by allowing consistent air circulation around food items, reducing moisture retention efficiently compared to netting bags. Netting bags, while useful for smaller or loose items, tend to restrict airflow and slow the dehydration process due to limited exposure. For optimal drying speed in dehydrating, air flow mesh trays outperform netting bags by maintaining superior ventilation and faster moisture evaporation.

Food Types Best Suited for Each Option

Which food types are best suited for netting bags versus air flow mesh trays in dehydrating? Netting bags excel at drying small, lightweight foods like herbs, berries, and leafy greens, preventing them from falling through the gaps. Air flow mesh trays are ideal for larger, thicker items such as fruit slices, vegetables, and jerky, allowing even air circulation and consistent drying throughout the pieces.

Ease of Use and Handling

Netting bags offer flexibility and compact storage for dehydrating small or irregular items, making them easy to handle and move. Air flow mesh trays provide a sturdy, flat surface that ensures even drying and simple stacking for efficient space use.

- Netting bags are lightweight - They can be easily filled, sealed, and hung or laid flat for convenient handling.

- Mesh trays provide structural stability - This reduces the chance of spills and makes transferring food items straightforward.

- Netting bags save space during storage - They can be folded or compressed, unlike rigid trays that require more room.

Cleaning and Maintenance Considerations

Netting bags require thorough cleaning to prevent food residue buildup, which can harbor bacteria and affect future batches. Air flow mesh trays often offer easier maintenance due to their rigid structure and dishwasher-safe materials.

Cleaning netting bags involves gentle hand washing and careful drying to maintain their shape and longevity, which can be time-consuming. In contrast, air flow mesh trays can typically be rinsed quickly or placed in a dishwasher for efficient sanitization. Choosing air flow mesh trays reduces the risk of mold growth and unpleasant odors associated with poorly dried netting bags.

Space Efficiency in Dehydrators

| Netting Bag | Offers high space efficiency by allowing flexible layering and compact stacking within dehydrators, optimizing use of vertical space. |

| Air Flow Mesh Tray | Provides structured airflow with less flexibility in stacking, often requiring more horizontal space but enhancing uniform drying. |

Longevity and Durability Analysis

Netting bags typically offer less durability compared to air flow mesh trays, as their fabric can weaken or tear after repeated use. Air flow mesh trays, constructed from high-grade stainless steel or reinforced plastic, ensure longer-lasting resilience against heat and moisture during cooking.

- Material Composition - Netting bags are often made from thin nylon or polyester fibers prone to wear under high temperatures.

- Structural Integrity - Air flow mesh trays maintain shape and strength over time due to sturdy metal or rigid plastic frames.

- Resistance to Environmental Factors - Mesh trays resist moisture, heat, and frequent cleaning better, enhancing longevity in dehydration processes.

Related Important Terms

Microclimate Drying Efficiency

Netting bags create a controlled microclimate by trapping moisture close to the food, enhancing dehydration efficiency for delicate items, while air flow mesh trays maximize air circulation and uniform drying by allowing 360-degree exposure to heated air. Optimizing the microclimate in netting bags can reduce drying time for herbs and small fruits, whereas mesh trays are ideal for larger, thicker foods requiring consistent airflow to prevent uneven drying and microbial growth.

Suspended Dehydration Zones

Netting bags create suspended dehydration zones by allowing air to circulate evenly around delicate foods, preventing contact with surfaces and promoting uniform drying. Air flow mesh trays also facilitate suspended dehydration but often offer less vertical air circulation, making netting bags more effective for maintaining optimal airflow in multi-layer drying setups.

360° Air Circulation Tray

A 360deg air circulation tray offers superior dehydration by ensuring even airflow around food, preventing moisture buildup and promoting uniform drying compared to netting bags. Unlike air flow mesh trays that only provide airflow from certain angles, the 360deg design maximizes drying efficiency and preserves texture and flavor during the cooking process.

Mold-Resistant Net Design

Mold-resistant netting bags feature tightly woven fibers that promote superior air circulation and moisture evaporation, minimizing mold growth during dehydration. Air flow mesh trays, while facilitating even drying with open grid patterns, often lack the dense weave necessary to fully prevent mold, making netting bags a more effective option for mold-resistant food preservation.

Anti-Static Mesh Grid

An anti-static mesh grid in netting bags prevents static buildup during dehydration, ensuring even airflow and consistent moisture removal from foods. Air flow mesh trays, while promoting ventilation, often lack anti-static properties, which can lead to clumping or uneven drying of ingredients.

Silicone-Coated Airflow Panels

Silicone-coated airflow panels in mesh trays provide superior heat distribution and moisture evaporation compared to traditional netting bags, enhancing the efficiency of dehydrating processes. Their durable, non-stick surface resists wear and allows for consistent air circulation, reducing drying times while preserving food quality.

Allergen-Barrier Eco Netting

Allergen-Barrier Eco Netting bags offer superior protection during dehydrating by preventing cross-contamination of allergens, unlike standard air flow mesh trays that allow more exposure to airborne particles. Their fine mesh design ensures optimal air circulation while maintaining a hygienic barrier, enhancing safety and quality in food dehydration processes.

Stackable Ventilation Racks

Stackable ventilation racks enhance airflow efficiency during dehydration by promoting even drying through improved air circulation, which is a key advantage over netting bags that can restrict airflow and cause uneven dehydration. Air flow mesh trays provide larger surface areas and better stackability, enabling consistent drying results and maximizing oven or dehydrator capacity compared to the limited stacking potential of netting bags.

Low-Touch Food Drying

Netting bags provide gentle, low-touch food drying by securely containing small pieces and reducing direct airflow contact, which preserves texture and nutritional quality during dehydration. Air flow mesh trays enhance even drying through optimized ventilation but may expose delicate foods to more direct air, risking surface drying and quality loss.

Netting bag vs Air flow mesh tray for cooking. Infographic

cookingdiff.com

cookingdiff.com