Using a jerky gun for homemade jerky offers precise control over thickness, ensuring even drying and optimal texture. A sausage stuffer, while primarily designed for ground meat, can be adapted for jerky but may lack the fine extrusion control leading to inconsistent slices. Choosing the right tool depends on desired jerky texture and ease of use, with jerky guns providing specialized functionality for dehydrating pet treats.

Table of Comparison

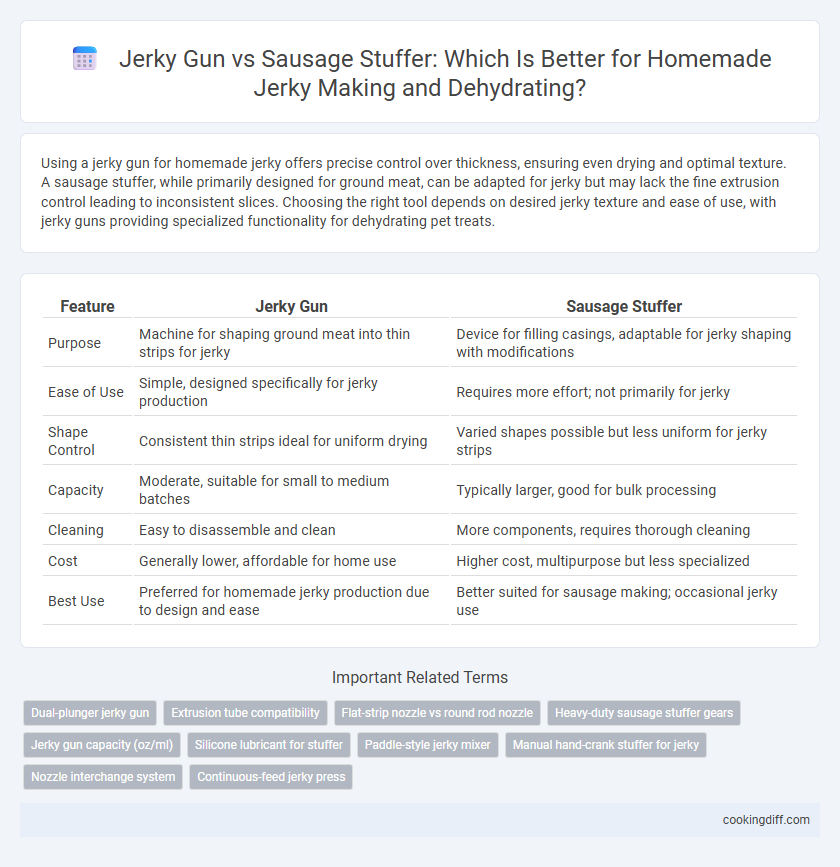

| Feature | Jerky Gun | Sausage Stuffer |

|---|---|---|

| Purpose | Machine for shaping ground meat into thin strips for jerky | Device for filling casings, adaptable for jerky shaping with modifications |

| Ease of Use | Simple, designed specifically for jerky production | Requires more effort; not primarily for jerky |

| Shape Control | Consistent thin strips ideal for uniform drying | Varied shapes possible but less uniform for jerky strips |

| Capacity | Moderate, suitable for small to medium batches | Typically larger, good for bulk processing |

| Cleaning | Easy to disassemble and clean | More components, requires thorough cleaning |

| Cost | Generally lower, affordable for home use | Higher cost, multipurpose but less specialized |

| Best Use | Preferred for homemade jerky production due to design and ease | Better suited for sausage making; occasional jerky use |

Introduction to Homemade Jerky Tools

Jerky guns and sausage stuffers are essential tools for homemade jerky enthusiasts, each designed to streamline the meat filling process. These devices help create uniform strips, ensuring consistent drying and flavor absorption.

Jerky guns operate by pressing ground meat through a narrow nozzle, shaping it directly onto dehydrator trays or sheets, making them ideal for thin, even jerky strips. Sausage stuffers, originally intended for sausage casings, can be adapted to fill jerky molds or tubes, allowing for larger batches and varied textures. Selecting between a jerky gun and a sausage stuffer depends on the desired jerky thickness, batch size, and ease of use for homemade dehydration projects.

What Is a Jerky Gun?

A jerky gun is a handheld device designed to extrude seasoned meat mixture through a tube, creating uniform strips ideal for dehydrating into jerky. It operates by pushing the meat through an adjustable nozzle, allowing control over the thickness and length of the jerky pieces.

Unlike sausage stuffers, jerky guns are specifically engineered for jerky-making, featuring attachments that produce jerky-sized strips rather than the round shapes typical of sausages. This specialization makes jerky guns more efficient for preparing high-quality homemade dehydrated jerky.

What Is a Sausage Stuffer?

| What Is a Sausage Stuffer? |

|---|

| A sausage stuffer is a kitchen tool designed to fill casings with ground meat, but it can also be effectively used for making homemade jerky by extruding thin, uniform strips or shapes of seasoned meat. Unlike a jerky gun, which is specifically crafted for jerky production with a simple squeeze mechanism, a sausage stuffer provides more control and pressure consistency, making it suitable for larger batches. This versatility allows users to customize jerky thickness and texture, enhancing the overall dehydration process. |

Key Differences: Jerky Gun vs Sausage Stuffer

Jerky guns are specifically designed for creating uniform strips of jerky with consistent thickness, making them ideal for quick and easy homemade jerky production. Sausage stuffers, while primarily used for filling casings, can be adapted for jerky but may lack the precise control over strip size and texture that jerky guns provide. The key difference lies in functionality: jerky guns offer specialized extrusion for jerky slices, whereas sausage stuffers focus on bulk filling, impacting the ease and quality of jerky preparation.

Ease of Use: Which Tool Is More User-Friendly?

Jerky guns are typically more user-friendly for beginners due to their straightforward design and simple operation. Sausage stuffers require more technique and setup, making them less intuitive for homemade jerky preparation.

- Jerky Gun Simplicity - Designed specifically for jerky, this tool often features easy loading and single-handed use, reducing the effort needed.

- Sausage Stuffer Complexity - Primarily intended for sausages, it demands more assembly and skill to achieve the correct pressure and consistency for jerky.

- Cleaning and Maintenance - Jerky guns usually have fewer parts and simpler cleaning procedures, enhancing overall ease of use for home dehydrators.

Consistency & Texture: Comparative Results

The jerky gun extrudes meat with uniform pressure, resulting in consistently thin strips that dry evenly for optimal texture. In contrast, sausage stuffers produce thicker, uneven cuts that can lead to inconsistent dehydration times and variable chewiness.

Using a jerky gun helps achieve a smooth, tender jerky texture by controlling strip thickness precisely. Sausage stuffers may cause irregular thickness, leading to jerky that is either overly dry or insufficiently cured in spots.

Capacity & Batch Sizes

Jerky guns typically allow smaller batch sizes, ideal for personal or occasional use with capacity around 1 to 2 pounds per feeding. Sausage stuffers offer larger capacity, often holding 5 pounds or more, suited for bulk jerky preparation.

- Jerky gun batch size - Designed for convenience, producing about 1-2 pounds per load, perfect for small-scale jerky making.

- Sausage stuffer capacity - Equipped with larger chambers, these machines can process multiple pounds at once, enhancing efficiency for bigger batches.

- Batch size optimization - Choosing between the two depends on desired jerky quantity and frequency, with sausage stuffers favoring volume production.

Cleaning and Maintenance Considerations

Jerky guns typically have fewer parts and simpler designs, making them easier to disassemble and clean thoroughly after each use. Sausage stuffers often contain more complex components, such as gears and tubes, which require detailed cleaning to prevent residue buildup and contamination. Regular maintenance of both tools ensures optimal performance and extends their lifespan during homemade jerky production.

Cost Efficiency: Investment and Value

Which tool offers better cost efficiency for homemade jerky making, a jerky gun or a sausage stuffer? Jerky guns generally have a lower upfront cost, making them accessible for beginners focused on small batches. Sausage stuffers involve a higher initial investment but provide greater versatility and long-term value for frequent jerky makers.

Related Important Terms

Dual-plunger jerky gun

The dual-plunger jerky gun offers superior control and consistent extrusion compared to traditional sausage stuffers, enabling precise shaping and thickness for homemade jerky. Its innovative dual-plunger design minimizes air pockets and speeds up the filling process, resulting in uniform dehydration and enhanced texture.

Extrusion tube compatibility

Jerky guns typically feature narrower extrusion tubes designed specifically for thin, uniform jerky strips, enhancing dehydration efficiency. Sausage stuffers often have wider tubes that may require specialized attachments to achieve consistent jerky thickness, potentially affecting drying time and texture quality.

Flat-strip nozzle vs round rod nozzle

A jerky gun with a flat-strip nozzle creates wide, uniform strips ideal for consistent drying, while a sausage stuffer with a round rod nozzle produces cylindrical shapes that may dry unevenly due to variable thickness. Flat-strip nozzles optimize airflow and moisture removal, enhancing dehydration efficiency compared to the round rod nozzle's tendency to trap moisture in dense, round forms.

Heavy-duty sausage stuffer gears

Heavy-duty sausage stuffer gears provide superior torque and durability, making them ideal for efficiently pushing tougher jerky mixtures through casings without frequent jams or breakdowns. Compared to jerky guns, these robust gears enable consistent pressure and smoother operation, resulting in uniform jerky strips essential for high-quality homemade dehydrated meat.

Jerky gun capacity (oz/ml)

Jerky guns typically offer a capacity ranging from 6 to 12 ounces (170 to 340 ml), allowing for precise and consistent extrusion of meat strips ideal for dehydrating. In contrast, sausage stuffers usually have larger capacities, exceeding 1 liter, but may lack the controlled output necessary for uniform jerky thickness.

Silicone lubricant for stuffer

Using a sausage stuffer with silicone lubricant enhances the smooth operation and durability of the equipment, preventing friction and clogging during the jerky-making process. In contrast, jerky guns typically require less maintenance but offer less control over texture and thickness compared to the precision achievable with a well-lubricated sausage stuffer.

Paddle-style jerky mixer

Paddle-style jerky mixers offer superior ingredient blending and texture consistency compared to traditional sausage stuffers, ensuring even distribution of marinades and spices in homemade jerky. These mixers enhance dehydration efficiency by thoroughly integrating meat fibers, resulting in jerky with optimal moisture retention and chewiness.

Manual hand-crank stuffer for jerky

A manual hand-crank jerky gun offers precise control over the thickness and shape of jerky strips, making it ideal for consistent drying and flavor absorption compared to bulk stuffing methods. Its compact design and easy-to-clean components enhance efficiency in homemade jerky production without the need for electricity, unlike sausage stuffers that are typically bulkier and less suited for fine, uniform jerky extrusion.

Nozzle interchange system

A jerky gun with a versatile nozzle interchange system enables precise shaping and consistent thickness for homemade jerky, enhancing drying efficiency and texture uniformity. In contrast, sausage stuffers typically have fewer nozzle options, limiting customization and potentially affecting the dehydration process due to uneven meat thickness.

Jerky gun vs Sausage stuffer for homemade jerky making Infographic

cookingdiff.com

cookingdiff.com