Paraflexx sheets offer superior flexibility and non-stick properties compared to Teflon sheets, making them ideal for dehydrating delicate foods such as pet treats. Unlike Teflon, Paraflexx sheets are more durable and resistant to high temperatures, ensuring consistent drying without sticking or tearing. This results in evenly dehydrated pet snacks that maintain their texture and nutritional value.

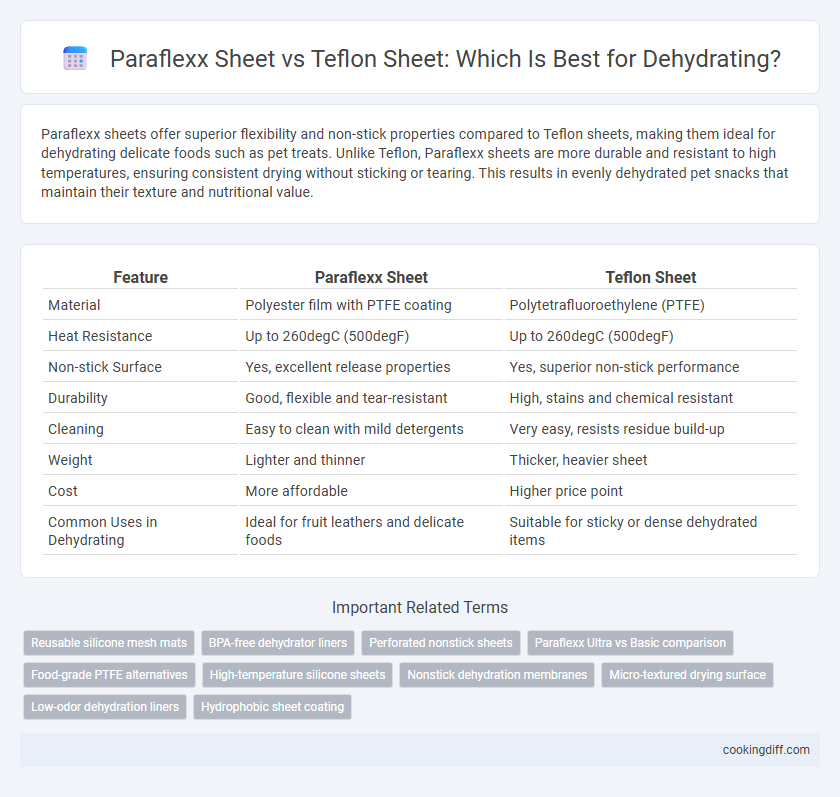

Table of Comparison

| Feature | Paraflexx Sheet | Teflon Sheet |

|---|---|---|

| Material | Polyester film with PTFE coating | Polytetrafluoroethylene (PTFE) |

| Heat Resistance | Up to 260degC (500degF) | Up to 260degC (500degF) |

| Non-stick Surface | Yes, excellent release properties | Yes, superior non-stick performance |

| Durability | Good, flexible and tear-resistant | High, stains and chemical resistant |

| Cleaning | Easy to clean with mild detergents | Very easy, resists residue build-up |

| Weight | Lighter and thinner | Thicker, heavier sheet |

| Cost | More affordable | Higher price point |

| Common Uses in Dehydrating | Ideal for fruit leathers and delicate foods | Suitable for sticky or dense dehydrated items |

Introduction to Dehydrator Sheets: Paraflexx vs Teflon

Dehydrator sheets like Paraflexx and Teflon are essential accessories that prevent food from sticking during the drying process. Paraflexx sheets are made of durable silicone-coated fiberglass, offering flexibility and reuse without compromising airflow. Teflon sheets, constructed from polytetrafluoroethylene, provide excellent non-stick properties but may lack the same level of pliability and heat resistance as Paraflexx.

Material Composition: Paraflexx and Teflon Explained

Paraflexx sheets are made from a nylon-based material that offers excellent flexibility and durability, making them suitable for repeated use in dehydrating processes. Teflon sheets, composed of polytetrafluoroethylene (PTFE), provide a non-stick surface with high chemical resistance and temperature tolerance up to 260degC (500degF).

Paraflexx material allows moisture to escape efficiently, promoting even dehydration while maintaining food texture. In contrast, Teflon sheets prevent food from sticking without compromising airflow but can degrade under excessive heat or mechanical stress over time.

Non-Stick Performance Comparison

Paraflexx sheets offer superior non-stick properties compared to traditional Teflon sheets, reducing food residue and making cleanup easier after dehydrating. Their advanced silicone coating resists sticking even with sticky or sugary foods, enhancing overall efficiency.

- Durability - Paraflexx sheets maintain non-stick performance longer under high heat conditions typical of dehydrating.

- Residue Resistance - Paraflexx sheets prevent sticky residues better than Teflon, minimizing the need for additional oils or sprays.

- Maintenance - Paraflexx sheets require less vigorous cleaning, preserving their non-stick surface compared to Teflon sheets.

Food Safety and Toxicity Concerns

Paraflexx sheets are made from a food-grade silicone material that offers excellent safety for dehydrating foods without releasing harmful chemicals. Teflon sheets, coated with polytetrafluoroethylene (PTFE), may pose toxicity concerns when exposed to high temperatures above 500degF, potentially releasing toxic fumes. For safe dehydrating practices, Paraflexx sheets are preferred due to their non-toxic, BPA-free composition and resistance to heat degradation.

Durability and Reusability

Paraflexx sheets offer superior durability compared to Teflon sheets, withstanding frequent use without cracking or peeling. Their reusability is enhanced by easier cleaning and longer lifespan, making them ideal for consistent dehydrating tasks.

- Durability Advantage - Paraflexx sheets resist wear and tear better than Teflon sheets under high heat conditions.

- Cleaning Efficiency - Paraflexx sheets are easier to clean, reducing the buildup of residue and maintaining usability.

- Extended Lifespan - Paraflexx's robust material allows for repeated use over multiple dehydration cycles without degradation.

Ease of Cleaning and Maintenance

Which sheet offers easier cleaning and maintenance for dehydrating purposes? Paraflexx sheets feature a non-stick surface that resists residue buildup, making them simpler to clean compared to Teflon sheets. Teflon sheets, while effective, often require more careful handling to avoid damage and maintain their non-stick properties over time.

Heat Resistance and Temperature Limitations

Paraflexx sheets offer superior heat resistance, withstanding temperatures up to 230degC, making them ideal for high-temperature dehydration processes. Teflon sheets typically have a maximum temperature limit around 260degC but may not provide consistent performance under prolonged heat exposure.

Paraflexx sheets maintain durability and flexibility at elevated temperatures, ensuring effective moisture removal without warping or degradation. Teflon sheets resist chemical reactions and are non-stick, yet their heat resistance can vary depending on thickness and quality. For precise temperature control during dehydration, Paraflexx sheets provide more reliable performance within the optimal range.

Suitability for Different Food Types

Paraflexx sheets offer excellent non-stick properties and are highly flexible, making them ideal for dehydrating sticky fruits and thinly sliced vegetables without tearing or sticking. Their heat resistance ensures uniform drying, which improves texture and preserves nutrients in delicate food items.

Teflon sheets, known for superior non-stick surfaces and durability, are well-suited for dehydrating meat jerky and thicker vegetable slices due to their ability to withstand higher temperatures and prolonged use. They provide even airflow and prevent moisture retention, which is crucial for safely dehydrating proteins and dense foods.

Cost Effectiveness and Value

Paraflexx sheets offer a more cost-effective solution compared to Teflon sheets for dehydrating due to their lower price and durable quality. While Teflon sheets provide excellent non-stick performance, Paraflexx balances value and efficiency, making it ideal for frequent use without high replacement costs.

- Lower initial cost - Paraflexx sheets are significantly cheaper to purchase than Teflon sheets, reducing upfront expenses.

- Durability - Paraflexx withstands repeated use and high temperatures, extending the lifespan and lowering long-term costs.

- Comparable non-stick properties - Paraflexx provides sufficient non-stick performance, minimizing food waste and cleaning time.

Overall, Paraflexx sheets provide superior cost effectiveness and value for dehydrating applications without compromising essential functionality.

Related Important Terms

Reusable silicone mesh mats

Reusable silicone mesh mats offer superior durability and non-stick properties compared to traditional Paraflexx and Teflon sheets, making them ideal for dehydrating fruits, vegetables, and herbs. Their flexible, heat-resistant design ensures even airflow and efficient drying while being easy to clean and environmentally friendly.

BPA-free dehydrator liners

Paraflexx sheets offer a BPA-free, non-stick alternative to traditional Teflon sheets, enhancing food safety during dehydration by preventing chemical leaching. Unlike Teflon sheets, Paraflexx liners provide superior flexibility and durability, making them ideal for repeated use in food dehydrators.

Perforated nonstick sheets

Perforated Paraflexx sheets offer superior airflow and moisture evaporation compared to traditional Teflon sheets, enhancing dehydration efficiency and ensuring even drying. Their nonstick, flexible design resists sticking and tearing, providing durability and easier food removal during dehydrating processes.

Paraflexx Ultra vs Basic comparison

Paraflexx Ultra sheets provide superior non-stick performance and higher heat resistance compared to Basic Teflon sheets, ensuring more efficient moisture removal during dehydrating processes. Their enhanced durability and flexible design prevent cracking and tearing, making them ideal for repeated use and precise drying applications.

Food-grade PTFE alternatives

Paraflexx sheets offer a food-grade PTFE alternative to traditional Teflon sheets for dehydrating, featuring enhanced chemical resistance and non-stick properties, making them ideal for safe food processing. These sheets ensure efficient moisture removal while maintaining FDA compliance and durability under high temperatures.

High-temperature silicone sheets

Paraflexx sheets, made from high-temperature silicone, offer superior flexibility, durability, and heat resistance up to 230degC, making them ideal for dehydrating applications compared to Teflon sheets, which typically have lower flexibility and can become brittle over time. The non-stick, food-safe surface of Paraflexx sheets ensures efficient moisture removal while maintaining product quality without the chemical concerns associated with some Teflon coatings.

Nonstick dehydration membranes

Paraflexx sheets offer superior nonstick dehydration membranes compared to Teflon sheets, ensuring easy release of dried foods without residue or sticking. Their enhanced flexibility and durability make Paraflexx sheets ideal for consistent airflow and even drying in dehydrators, outperforming traditional Teflon options.

Micro-textured drying surface

Paraflexx sheets feature a micro-textured drying surface that enhances air circulation and moisture removal during dehydrating, offering faster and more even drying compared to the smooth surface of Teflon sheets. This micro-texture reduces drying time and preserves the texture and flavor of dehydrated foods more effectively than Teflon sheets.

Low-odor dehydration liners

Paraflexx sheets offer superior low-odor dehydration liners compared to Teflon sheets, providing enhanced resistance to sticking and contamination-free drying processes. Their high-temperature tolerance and food-grade polymer composition ensure optimal flavor retention and hygienic dehydration results.

Paraflexx sheet vs Teflon sheet for dehydrating. Infographic

cookingdiff.com

cookingdiff.com