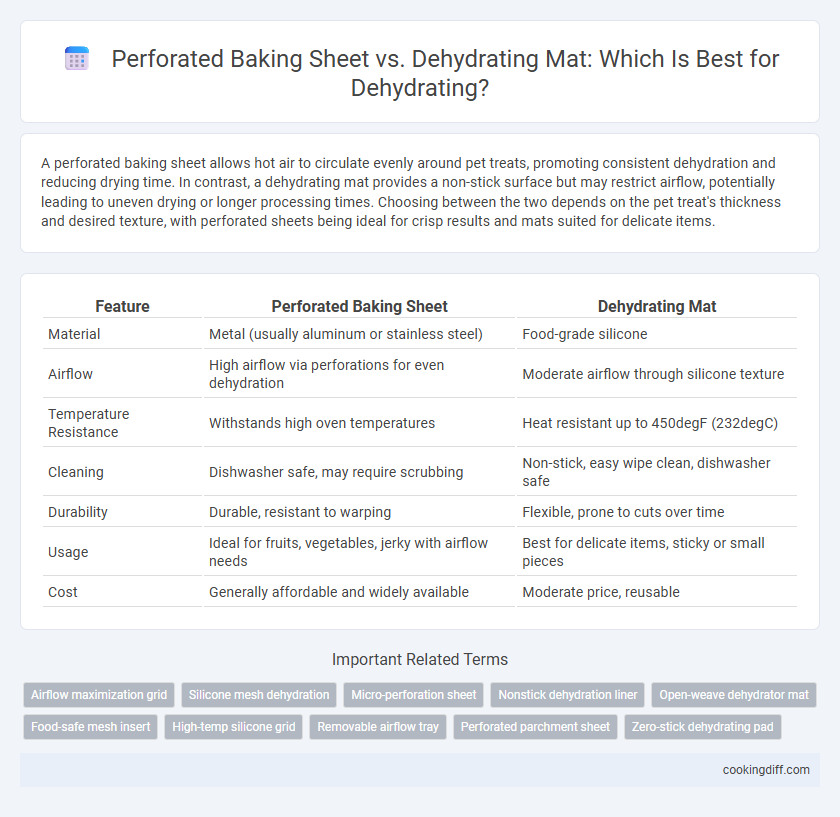

A perforated baking sheet allows hot air to circulate evenly around pet treats, promoting consistent dehydration and reducing drying time. In contrast, a dehydrating mat provides a non-stick surface but may restrict airflow, potentially leading to uneven drying or longer processing times. Choosing between the two depends on the pet treat's thickness and desired texture, with perforated sheets being ideal for crisp results and mats suited for delicate items.

Table of Comparison

| Feature | Perforated Baking Sheet | Dehydrating Mat |

|---|---|---|

| Material | Metal (usually aluminum or stainless steel) | Food-grade silicone |

| Airflow | High airflow via perforations for even dehydration | Moderate airflow through silicone texture |

| Temperature Resistance | Withstands high oven temperatures | Heat resistant up to 450degF (232degC) |

| Cleaning | Dishwasher safe, may require scrubbing | Non-stick, easy wipe clean, dishwasher safe |

| Durability | Durable, resistant to warping | Flexible, prone to cuts over time |

| Usage | Ideal for fruits, vegetables, jerky with airflow needs | Best for delicate items, sticky or small pieces |

| Cost | Generally affordable and widely available | Moderate price, reusable |

Introduction to Dehydrating with Perforated Baking Sheets and Dehydrating Mats

Perforated baking sheets enhance airflow during dehydrating, promoting even drying and crisp texture. Dehydrating mats offer a non-stick surface ideal for delicate fruits and vegetables, preventing loss through holes while maintaining consistent drying.

Perforated baking sheets are typically made of metal with evenly spaced holes, allowing moisture to escape efficiently and speeding up the dehydrating process. Dehydrating mats, usually silicone, provide versatility as they can be cut to size and reused, making them environmentally friendly. Choosing between these tools depends on the food type and drying preferences for optimal results.

Material Comparison: Perforated Baking Sheet vs Dehydrating Mat

Perforated baking sheets are typically made from metal, allowing for excellent airflow and even heat distribution during dehydration. Dehydrating mats are usually constructed from non-stick silicone, providing a reusable and flexible surface ideal for delicate foods.

- Perforated Baking Sheet Material - Metal construction promotes durability and efficient air circulation.

- Dehydrating Mat Material - Silicone offers a non-stick, easy-to-clean surface that prevents sticking.

- Heat Conductivity - Metal sheets conduct heat faster than silicone mats, potentially reducing drying time.

Airflow Efficiency: Which Option Promotes Better Dehydration?

Perforated baking sheets offer superior airflow efficiency by allowing air to circulate freely around the food, promoting faster and more even dehydration. Dehydrating mats, while convenient, often restrict airflow beneath the food, potentially leading to uneven drying and longer processing times.

- Perforated Design - Enables optimal air circulation, enhancing moisture removal from all sides of the food.

- Material Thickness - Thinner, rigid baking sheets maintain open airflow compared to flexible dehydrating mats that can block air channels.

- Heat Distribution - Perforated sheets facilitate consistent heat exposure due to better ventilation, resulting in uniform dehydration.

Choosing a perforated baking sheet typically results in improved dehydration efficiency and quality compared to a dehydrating mat.

Food Sticking and Cleanup: Ease of Use and Maintenance

Perforated baking sheets allow airflow to circulate around the food, reducing sticking but may require frequent cleaning to remove food particles trapped in the holes. The textured surface can sometimes cause delicate foods to adhere, necessitating careful handling during removal.

Dehydrating mats, made from non-stick materials like silicone or Teflon, significantly minimize food sticking, offering an easier release of dried items. Cleanup is simplified since mats can be wiped or washed without scrubbing, enhancing maintenance convenience for repeated use.

Versatility in the Kitchen: More Than Just Dehydration

Which kitchen tool offers greater versatility beyond just dehydrating foods? Perforated baking sheets provide excellent airflow for even drying and can be used for grilling or baking crispy snacks, enhancing their functionality. Dehydrating mats, typically silicone-based, offer a non-stick surface suitable for rolling out dough or roasting vegetables, making them a multifunctional kitchen accessory.

Temperature Tolerance and Heat Distribution

Perforated baking sheets typically tolerate oven temperatures up to 450degF, allowing for high-heat dehydrating without warping, while dehydrating mats often withstand temperatures around 160degF to 180degF, making them suitable for low-temperature food dehydration. The metal construction of perforated sheets ensures even heat distribution, preventing hot spots and promoting uniform drying.

Dehydrating mats, usually made of silicone or Teflon, offer non-stick surfaces but may have slightly uneven heat distribution due to their flexible material, which can affect drying consistency. Users prioritizing precise temperature control and even air flow benefit from perforated baking sheets, while mats are preferred for gentle drying and easy cleanup.

Durability and Longevity of Each Dehydrating Surface

Perforated baking sheets, typically made from aluminum, offer excellent durability due to their rigid construction, allowing for repeated use without warping or damage. Dehydrating mats, often composed of silicone or Teflon, provide long-lasting flexibility and resistance to heat but may wear down faster with frequent heavy use or improper cleaning. Both surfaces maintain longevity when cared for properly, but silicone mats tend to retain non-stick properties longer, enhancing ease of food removal during dehydration.

Safety Considerations: Food-Grade Materials and Health Impacts

Choosing food-grade materials is crucial when selecting between perforated baking sheets and dehydrating mats to ensure safety and avoid chemical contamination during dehydrating. Perforated baking sheets made from stainless steel or aluminum are often preferred for their non-toxic properties, while some dehydrating mats may contain non-food-grade plastics that risk leaching harmful substances.

- Food-Grade Certification - Only use perforated sheets and mats explicitly labeled as food-grade to prevent exposure to toxic chemicals.

- Material Composition - Stainless steel perforated sheets resist corrosion and do not release chemicals compared to plastic mats which may degrade under heat.

- Health Impacts - Using non-food-grade dehydrating mats can lead to ingestion of harmful compounds, impacting long-term health during food preservation.

Cost-Effectiveness: Upfront Investment and Long-Term Savings

Perforated baking sheets typically offer a lower upfront cost compared to dehydrating mats, making them a budget-friendly option for beginners. Dehydrating mats, while more expensive initially, provide long-term savings by promoting even airflow and reducing drying time, which decreases energy consumption. Investing in a dehydrating mat can result in better quality preservation and overall efficiency, offsetting the higher initial price over time.

Related Important Terms

Airflow maximization grid

A perforated baking sheet features a grid of holes that maximizes airflow, promoting even moisture removal during dehydrating, while a dehydrating mat typically offers a solid surface with limited ventilation. This airflow maximization grid is critical for efficient dehydration, reducing drying time and improving the texture and preservation of foods.

Silicone mesh dehydration

Silicone mesh dehydration mats offer superior airflow and non-stick surfaces compared to perforated baking sheets, enhancing moisture removal and preserving delicate food textures. These mats provide even heat distribution and flexibility for easy cleaning, making them ideal for efficient and consistent drying in food dehydrators.

Micro-perforation sheet

Micro-perforation sheets offer superior airflow compared to solid dehydrating mats, promoting even drying by allowing moisture to escape more efficiently during the dehydration process. Their design minimizes drying time and reduces the risk of mold formation, making them ideal for preserving fruits, vegetables, and herbs.

Nonstick dehydration liner

A nonstick dehydration liner, such as a perforated baking sheet, enhances airflow and prevents food from sticking during the dehydrating process, ensuring even drying and easy removal. Compared to solid dehydrating mats, perforated liners improve moisture escape, resulting in more consistent texture and reduced drying time for fruits, vegetables, and meats.

Open-weave dehydrator mat

Open-weave dehydrator mats provide superior airflow compared to perforated baking sheets, enhancing moisture evaporation and ensuring evenly dehydrated foods. Their breathable mesh design prevents small pieces from falling through while promoting efficient drying, making them ideal for consistent, high-quality dehydration results.

Food-safe mesh insert

A food-safe mesh insert on a perforated baking sheet ensures even airflow and prevents small food pieces from falling through during dehydrating, enhancing drying efficiency. Dehydrating mats typically offer a non-stick surface but may lack the structured perforations that maximize air circulation for consistent dehydration results.

High-temp silicone grid

A high-temp silicone grid used as a dehydrating mat provides superior airflow and even heat distribution compared to perforated baking sheets, ensuring consistent moisture removal from fruits and vegetables. Its non-stick, flexible surface also facilitates easy food release and cleanup while withstanding temperatures up to 500degF, making it ideal for efficient dehydration.

Removable airflow tray

A removable airflow tray enhances even drying by allowing consistent air circulation beneath foods, essential for effective dehydration. Perforated baking sheets provide basic airflow but lack the versatility and easy cleaning offered by silicone dehydrating mats with removable trays designed for optimal dehydration performance.

Perforated parchment sheet

A perforated parchment sheet allows airflow around food items during dehydrating, enhancing moisture removal and reducing drying time compared to a solid dehydrating mat. Its non-stick surface prevents sticking and simplifies cleanup while ensuring even heat circulation for consistent dehydration results.

Perforated baking sheet vs dehydrating mat for dehydrating. Infographic

cookingdiff.com

cookingdiff.com