Conventional dehydrators use heated air circulation to remove moisture from vegetables, ensuring even drying but often requiring longer processing times and higher energy consumption. Infrared dehydrators utilize infrared radiation to penetrate vegetables, resulting in faster drying speeds and better nutrient retention while consuming less energy. Choosing between the two depends on priorities like drying efficiency, energy savings, and preserving vegetable quality.

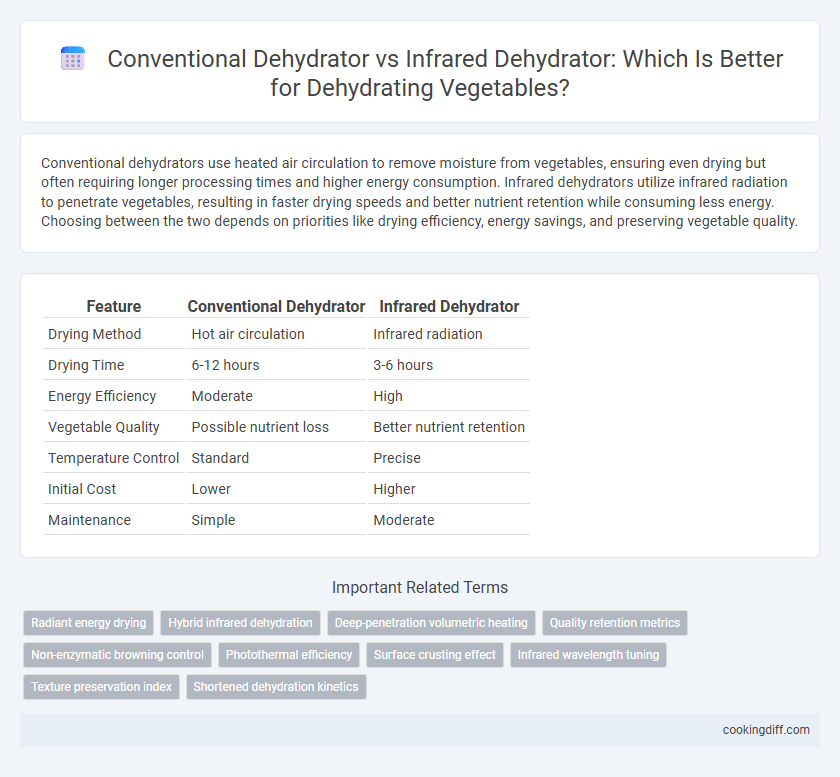

Table of Comparison

| Feature | Conventional Dehydrator | Infrared Dehydrator |

|---|---|---|

| Drying Method | Hot air circulation | Infrared radiation |

| Drying Time | 6-12 hours | 3-6 hours |

| Energy Efficiency | Moderate | High |

| Vegetable Quality | Possible nutrient loss | Better nutrient retention |

| Temperature Control | Standard | Precise |

| Initial Cost | Lower | Higher |

| Maintenance | Simple | Moderate |

Introduction to Vegetable Dehydration Methods

Conventional dehydrators use heated air circulation to remove moisture from vegetables, ensuring even drying and preservation. Infrared dehydrators employ radiant heat for faster drying times and enhanced nutrient retention. Both methods aim to extend shelf life while maintaining texture and flavor of vegetables.

How Conventional Dehydrators Work

Conventional dehydrators use a fan to circulate warm air generated by an electric heating element, which removes moisture from vegetables through evaporation. This process slows bacterial growth, preserving the vegetables' structure and nutrients over time.

The heated air passes evenly over slices or pieces in trays, allowing surface moisture to evaporate steadily. Moisture escapes into the air and is expelled, preventing reabsorption by the vegetables. This method typically requires temperatures between 120degF to 160degF and several hours to effectively dehydrate vegetables.

The Science Behind Infrared Dehydrators

How does the science behind infrared dehydrators enhance vegetable dehydration compared to conventional methods? Infrared dehydrators use electromagnetic radiation to penetrate vegetables, causing water molecules to vibrate and evaporate more efficiently. This targeted heating preserves nutrients and reduces drying time, unlike conventional dehydrators that rely on hot air circulation, which can lead to uneven drying and nutrient loss.

Energy Efficiency: Conventional vs Infrared

Infrared dehydrators use radiant heat to penetrate vegetables, resulting in faster drying times and lower energy consumption compared to conventional dehydrators. Conventional units rely on heated air circulation that can lead to longer drying cycles and increased power usage for similar vegetable loads.

- Infrared technology reduces drying time - By directly heating the vegetable's surface, infrared dehydrators significantly cut down energy use by shortening operation periods.

- Conventional dehydrators consume more energy - Extended drying times with heated air circulation result in higher electricity consumption for comparable batches of vegetables.

- Energy efficiency impacts cost and sustainability - Infrared units offer long-term savings and a smaller carbon footprint, making them preferable for eco-conscious users.

Dehydration Speed and Time Comparison

Conventional dehydrators use heated air circulation, achieving dehydration speeds ranging from 6 to 12 hours depending on vegetable type and thickness. Infrared dehydrators utilize infrared radiation to penetrate food, reducing dehydration time by up to 30% compared to conventional methods.

Vegetables like carrots and bell peppers typically require 8-10 hours in conventional dehydrators, while infrared dehydrators complete the process in approximately 5-7 hours. The faster dehydration time in infrared units helps retain more nutrients and color in vegetables during drying.

Nutrient Retention in Dehydrated Vegetables

| Dehydrator Type | Nutrient Retention | Key Benefits |

|---|---|---|

| Conventional Dehydrator | Moderate retention of vitamins such as vitamin C and B-complex due to prolonged drying time at lower temperatures. | Even drying process, widely available, preserves texture but can lead to nutrient loss over extended drying periods. |

| Infrared Dehydrator | Higher retention of sensitive nutrients like antioxidants, vitamin C, and carotenoids because of faster dehydration and reduced exposure to heat and oxygen. | Efficient energy use, quicker drying times, better preservation of color and flavor, enhancing overall nutritional quality. |

Texture and Flavor Differences

Conventional dehydrators use hot air circulation to remove moisture, often resulting in a chewier texture and slightly muted flavors in vegetables. Infrared dehydrators penetrate vegetables with radiant heat, preserving a crisper texture and enhancing natural flavors through more uniform drying.

Vegetables dried with infrared technology retain vibrant color and better maintain nutritional content, improving overall taste intensity. In contrast, conventional methods may cause uneven drying, leading to variable texture and flavor profiles.

Ease of Use and Maintenance

Conventional dehydrators typically feature straightforward controls and removable trays, making them user-friendly and easy to clean. Infrared dehydrators often incorporate advanced technology that may require more careful maintenance but offer quicker drying times.

- Ease of Use - Conventional models usually have simple, manual settings ideal for beginners.

- Maintenance - Removable parts in conventional dehydrators allow for easy washing and upkeep.

- Infrared Efficiency - Infrared units dry vegetables faster but might have components that need delicate care.

Choosing between these options depends on balancing convenience in daily use with the desired drying speed and maintenance effort.

Cost Analysis and Long-Term Value

Infrared dehydrators typically have a higher initial purchase price compared to conventional dehydrators but offer faster drying times, reducing energy costs over time. Conventional dehydrators are more affordable upfront but may incur higher long-term electricity expenses due to longer operating hours.

- Initial Cost - Infrared dehydrators can cost 20-40% more than conventional models.

- Energy Efficiency - Infrared technology reduces drying time by up to 30%, lowering electricity consumption.

- Long-Term Value - Faster drying and lower energy use make infrared dehydrators more cost-effective over several years.

Related Important Terms

Radiant energy drying

Conventional dehydrators use hot air circulation to remove moisture from vegetables, relying primarily on convective heat transfer, whereas infrared dehydrators employ radiant energy that penetrates the vegetable surface, enhancing drying efficiency and preserving nutritional content. Infrared drying accelerates moisture evaporation by directly targeting water molecules, resulting in faster dehydration times and improved texture retention compared to traditional methods.

Hybrid infrared dehydration

Hybrid infrared dehydration combines the efficiency of conventional dehydrators with the rapid drying capability of infrared technology, resulting in enhanced moisture removal and better nutrient retention in vegetables. This method reduces drying time by up to 40% while preserving texture and color more effectively than traditional or standalone infrared dehydrators.

Deep-penetration volumetric heating

Infrared dehydrators utilize deep-penetration volumetric heating, allowing heat to penetrate vegetables uniformly, resulting in faster and more energy-efficient dehydration compared to conventional dehydrators that rely on surface heating and air circulation. This advanced heating method preserves nutrients and texture by reducing dehydration time and minimizing thermal degradation.

Quality retention metrics

Conventional dehydrators often result in higher nutrient degradation due to prolonged exposure to heat, leading to lower retention of vitamins such as vitamin C and antioxidants in dehydrated vegetables. Infrared dehydrators use shorter drying times and targeted heat penetration, significantly improving moisture removal efficiency while preserving color, texture, and essential phytonutrients for superior quality retention.

Non-enzymatic browning control

Infrared dehydrators effectively minimize non-enzymatic browning in vegetables by providing precise, uniform heat that reduces Maillard reaction incidences compared to conventional dehydrators. Conventional dehydrators often cause uneven drying and higher temperatures, accelerating browning and compromising vegetable color and nutritional quality.

Photothermal efficiency

Conventional dehydrators rely on heated air circulation to remove moisture, often resulting in lower photothermal efficiency and longer drying times for vegetables. Infrared dehydrators utilize targeted infrared radiation that penetrates the cellular structure, enhancing photothermal efficiency and preserving nutrient content more effectively during dehydration.

Surface crusting effect

Conventional dehydrators often cause surface crusting on vegetables due to uneven heat distribution and slower moisture removal, leading to a tougher outer layer that traps internal moisture. Infrared dehydrators minimize surface crusting by providing rapid, uniform heating that penetrates deeper, allowing more consistent drying and better texture retention.

Infrared wavelength tuning

Infrared dehydrators utilize precise wavelength tuning to target specific moisture absorption spectra in vegetables, enhancing drying efficiency and preserving nutritional content compared to conventional dehydrators. This wavelength optimization accelerates dehydration rates while reducing energy consumption and minimizing thermal damage to delicate vegetable tissues.

Texture preservation index

Conventional dehydrators use hot air to remove moisture from vegetables, often resulting in a lower texture preservation index due to prolonged drying times and uneven heat distribution. Infrared dehydrators preserve vegetable texture more effectively by delivering rapid, uniform heat that minimizes cell damage and maintains crispness.

Conventional dehydrator vs infrared dehydrator for vegetables. Infographic

cookingdiff.com

cookingdiff.com