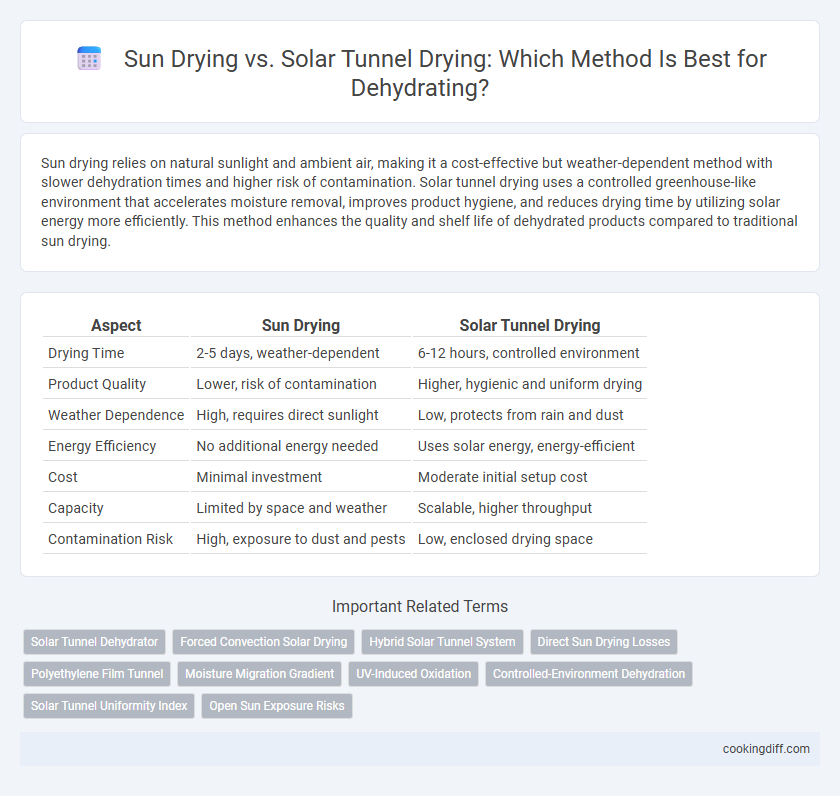

Sun drying relies on natural sunlight and ambient air, making it a cost-effective but weather-dependent method with slower dehydration times and higher risk of contamination. Solar tunnel drying uses a controlled greenhouse-like environment that accelerates moisture removal, improves product hygiene, and reduces drying time by utilizing solar energy more efficiently. This method enhances the quality and shelf life of dehydrated products compared to traditional sun drying.

Table of Comparison

| Aspect | Sun Drying | Solar Tunnel Drying |

|---|---|---|

| Drying Time | 2-5 days, weather-dependent | 6-12 hours, controlled environment |

| Product Quality | Lower, risk of contamination | Higher, hygienic and uniform drying |

| Weather Dependence | High, requires direct sunlight | Low, protects from rain and dust |

| Energy Efficiency | No additional energy needed | Uses solar energy, energy-efficient |

| Cost | Minimal investment | Moderate initial setup cost |

| Capacity | Limited by space and weather | Scalable, higher throughput |

| Contamination Risk | High, exposure to dust and pests | Low, enclosed drying space |

Introduction to Dehydration: Why Dry Foods?

Dehydration preserves food by removing moisture that causes spoilage, extending shelf life and maintaining nutritional value. Sun drying and solar tunnel drying are common methods that utilize natural energy for efficient moisture removal.

- Sun drying - Food is spread under direct sunlight, relying on ambient temperature and airflow to reduce moisture content.

- Solar tunnel drying - Food is dried inside a greenhouse-like tunnel that concentrates solar heat and improves drying speed and hygiene.

- Dehydration benefits - Both methods reduce microbial growth and enzymatic activity to preserve food quality and safety.

Overview of Sun Drying: Traditional Methods

Sun drying is a traditional dehydration method that relies on natural sunlight to remove moisture from food products. It is cost-effective and widely practiced in rural areas, utilizing open-air spaces or simple drying racks.

However, sun drying is weather-dependent and exposes products to contamination from dust, insects, and animals, which can affect quality and safety. The process is slower compared to modern methods, often requiring several days to achieve desired moisture levels.

Understanding Solar Tunnel Drying Technology

| Sun Drying | Relies on natural sunlight and ambient air, making it cost-effective but dependent on weather conditions and prone to contamination and uneven drying. |

| Solar Tunnel Drying | Utilizes a greenhouse-like structure with transparent cover and forced air circulation to create controlled drying conditions, enhancing drying speed, hygiene, and product quality. |

| Advantages of Solar Tunnel Drying | Offers consistent temperature and humidity control, reduces drying time by up to 50%, and minimizes microbial contamination compared to traditional sun drying. |

| Technical Components | Includes solar air heaters, ventilation ducts, and exhaust fans to optimize airflow and solar radiation absorption, ensuring efficient dehydration of fruits, vegetables, and herbs. |

Comparative Efficiency: Drying Time and Moisture Removal

Which method offers superior drying time and moisture removal efficiency: sun drying or solar tunnel drying? Solar tunnel drying significantly reduces drying time by using controlled airflow and temperature, achieving faster and more uniform dehydration compared to traditional sun drying. Sun drying depends on weather conditions and often results in inconsistent moisture removal, making solar tunnel drying more reliable for preserving product quality and extending shelf life.

Quality of Dehydrated Products: Nutrients, Flavor, and Color

Sun drying often results in lower retention of nutrients such as vitamins A and C due to prolonged exposure to direct sunlight and fluctuating temperatures. Solar tunnel drying provides more controlled conditions that enhance the preservation of flavor compounds and maintain vibrant color by minimizing oxidation and microbial growth. Both methods affect the quality of dehydrated products, but solar tunnel drying generally yields superior nutrient retention and overall product quality.

Weather Dependence: Impact of Climate and Season

Sun drying is highly weather-dependent, requiring consistent sunlight and low humidity for effective dehydration, making it less reliable during rainy or overcast periods. Seasonal variations significantly affect drying times and product quality, with cooler or humid seasons prolonging the process and increasing the risk of spoilage.

Solar tunnel drying offers more controlled conditions and reduced reliance on immediate weather, utilizing enclosed spaces that protect produce from rain and fluctuating temperatures. This method ensures more consistent dehydration throughout varying climate conditions and seasonal changes, improving efficiency and product preservation.

Hygiene and Food Safety Considerations

Sun drying exposes food to open air and dust, increasing contamination risks from insects, animals, and microorganisms, which can compromise hygiene and food safety. Solar tunnel drying uses enclosed chambers with controlled airflow and temperature, significantly reducing exposure to contaminants and enhancing microbial safety. This method ensures a more consistent drying environment, lowering the risk of spoilage and foodborne illnesses compared to traditional sun drying.

Cost and Accessibility: Investment and Maintenance

Sun drying requires minimal initial investment and low maintenance, making it highly accessible for small-scale farmers. Solar tunnel drying demands higher upfront costs and routine maintenance but offers faster and more consistent dehydration results.

- Low Investment - Sun drying involves simple infrastructure, reducing financial barriers for users.

- Higher Investment - Solar tunnel drying needs materials like plastic sheets and frames, increasing startup expenses.

- Maintenance Requirements - Solar tunnels require regular cleaning and repairs, unlike virtually maintenance-free sun drying.

Choosing between methods depends on budget constraints and desired drying efficiency.

Environmental Impact: Energy Use and Sustainability

Sun drying consumes no external energy, relying entirely on natural sunlight, which makes it the most environmentally sustainable method for dehydrating. This process has a minimal carbon footprint but depends heavily on weather conditions and extended drying times.

Solar tunnel drying utilizes solar panels and controlled airflow to enhance drying efficiency, resulting in reduced energy consumption compared to conventional electric dryers. Its energy use is low and primarily sourced from renewable solar energy, contributing to sustainability goals by minimizing fossil fuel dependency. However, the initial setup requires materials and maintenance, which influences the overall environmental impact.

Related Important Terms

Solar Tunnel Dehydrator

Solar tunnel dehydrators offer enhanced dehydration efficiency by utilizing a controlled environment that accelerates moisture removal while preserving nutritional quality and color compared to traditional sun drying. This method reduces contamination risks and drying time by maintaining higher temperatures and lower humidity, resulting in consistent product quality and increased shelf life.

Forced Convection Solar Drying

Forced convection solar drying in solar tunnel dryers enhances dehydration efficiency by circulating heated air uniformly, reducing drying time compared to traditional sun drying methods. This method minimizes contamination risks and preserves nutrient content by maintaining controlled temperature and airflow, leading to superior quality dried products.

Hybrid Solar Tunnel System

Hybrid Solar Tunnel Systems combine the energy efficiency of solar tunnel drying with supplemental heat sources to optimize dehydration processes, achieving faster drying times and improved product quality compared to traditional sun drying methods. These systems enhance moisture removal rates while minimizing contamination risks, offering a reliable, sustainable alternative that outperforms both conventional sun drying and standard solar tunnel drying techniques.

Direct Sun Drying Losses

Direct sun drying causes significant nutrient and moisture losses due to uncontrolled exposure to environmental factors, resulting in reduced product quality and shelf life. In contrast, solar tunnel drying minimizes these losses by providing a controlled drying environment that preserves nutritional content and ensures uniform dehydration.

Polyethylene Film Tunnel

Sun drying relies on natural sunlight and ambient air, often leading to inconsistent dehydration and higher contamination risks, while solar tunnel drying using polyethylene film tunnels offers controlled temperature and humidity conditions that enhance drying efficiency and product quality; polyethylene film's UV resistance and moisture retention properties optimize the dehydrating environment, reducing microbial growth and preserving nutritional content.

Moisture Migration Gradient

Sun drying relies on natural sunlight and ambient air, resulting in an inconsistent moisture migration gradient that often causes uneven dehydration and prolonged drying times. Solar tunnel drying creates a controlled environment with a consistent temperature and airflow, promoting a uniform moisture migration gradient that enhances drying efficiency and product quality.

UV-Induced Oxidation

Sun drying exposes produce to direct sunlight, resulting in higher UV-induced oxidation that can degrade nutrients and reduce shelf life; solar tunnel drying minimizes UV exposure by using controlled airflow and shading, preserving antioxidants and enhancing product quality during dehydration. Reduced UV radiation in solar tunnel drying significantly lowers oxidative stress on food, maintaining better color, flavor, and nutritional value compared to traditional sun drying methods.

Controlled-Environment Dehydration

Solar tunnel drying offers a controlled-environment dehydration process that maintains consistent temperature and humidity levels, significantly reducing microbial contamination compared to traditional sun drying. This method enhances product quality and shelf life by providing uniform drying conditions and protection from external contaminants.

Solar Tunnel Uniformity Index

Solar tunnel drying achieves a higher Uniformity Index compared to sun drying, ensuring more consistent temperature and airflow distribution throughout the drying chamber. This uniformity enhances the dehydration quality by reducing uneven moisture content and minimizing microbial growth risks.

Sun drying vs Solar tunnel drying for dehydrating. Infographic

cookingdiff.com

cookingdiff.com