Desiccant drying relies on moisture-absorbing materials to extract water from mushrooms, providing a low-temperature, energy-efficient method that preserves flavor and nutrients. Ultrasonic dehydrators use high-frequency vibrations to accelerate water removal, offering faster drying times but potentially risking texture changes or nutrient loss. Choosing between them depends on priorities like drying speed, energy consumption, and the desired quality of the final product.

Table of Comparison

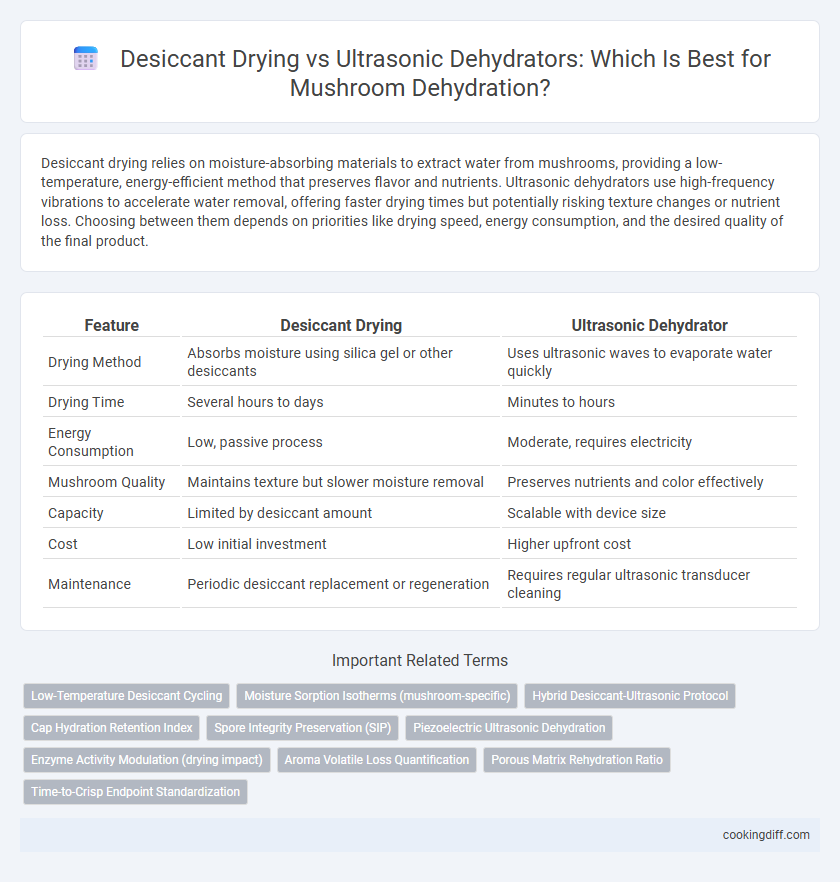

| Feature | Desiccant Drying | Ultrasonic Dehydrator |

|---|---|---|

| Drying Method | Absorbs moisture using silica gel or other desiccants | Uses ultrasonic waves to evaporate water quickly |

| Drying Time | Several hours to days | Minutes to hours |

| Energy Consumption | Low, passive process | Moderate, requires electricity |

| Mushroom Quality | Maintains texture but slower moisture removal | Preserves nutrients and color effectively |

| Capacity | Limited by desiccant amount | Scalable with device size |

| Cost | Low initial investment | Higher upfront cost |

| Maintenance | Periodic desiccant replacement or regeneration | Requires regular ultrasonic transducer cleaning |

Introduction to Mushroom Dehydration Methods

Mushroom dehydration preserves shelf life and enhances flavor through moisture removal. Choosing between desiccant drying and ultrasonic dehydration depends on desired drying speed and texture retention.

- Desiccant Drying - Utilizes moisture-absorbing materials to slowly remove water at low temperatures, preserving mushroom integrity.

- Ultrasonic Dehydrator - Employs high-frequency vibrations to accelerate water removal while maintaining structural quality.

- Comparison - Desiccant drying is energy-efficient but slower, whereas ultrasonic dehydrators offer faster drying with potential equipment costs.

Overview of Desiccant Drying for Mushrooms

| Method | Desiccant Drying for Mushrooms |

|---|---|

| Process | Uses moisture-absorbing substances like silica gel or activated charcoal to remove water from mushrooms at ambient temperatures. |

| Advantages | Maintains mushroom structure and nutritional content by avoiding heat damage; energy-efficient and quiet operation. |

| Limitations | Slower drying times compared to ultrasonic methods; requires regular replacement or regeneration of desiccant materials. |

How Ultrasonic Dehydrators Work

Ultrasonic dehydrators use high-frequency sound waves to create microscopic vibrations that remove moisture from mushrooms without applying heat. This preservation method retains the mushroom's natural flavor, texture, and nutrients more effectively than traditional drying techniques.

The ultrasonic process generates cavitation bubbles in the moisture, which collapse and release energy that breaks down water molecules, facilitating rapid evaporation. Unlike desiccant drying, which absorbs moisture through hygroscopic materials, ultrasonic dehydration works physically on the water content itself. This technology offers a gentle, energy-efficient alternative to conventional methods, ideal for preserving delicate fungi.

Efficiency Comparison: Desiccant vs Ultrasonic Dehydration

Desiccant drying removes moisture from mushrooms by absorbing water vapor, resulting in slower but highly effective dehydration. Ultrasonic dehydrators use high-frequency vibrations to rapidly expel moisture, offering faster drying times but sometimes less uniform results.

- Desiccant Moisture Absorption - Relies on chemical agents to trap water molecules, ensuring low final moisture content.

- Ultrasonic Speed - Accelerates drying by disrupting water membranes through ultrasonic waves.

- Energy Consumption - Ultrasonic dehydrators typically consume more power compared to passive desiccant methods.

Desiccant drying is more energy-efficient but slower, while ultrasonic dehydration offers speed with higher energy costs and variable consistency.

Impact on Mushroom Texture and Flavor

Desiccant drying preserves mushroom flavor by gently absorbing moisture, resulting in a chewy texture that maintains natural earthiness. Ultrasonic dehydrators generate fine vibrations that can alter cell structure, often causing a more brittle texture and slight flavor loss.

Desiccant drying retains antioxidants and volatile compounds better, enhancing umami intensity in dried mushrooms. Ultrasonic dehydration may reduce these compounds, impacting overall taste complexity and freshness perception.

Nutrient Retention: Which Method Performs Better?

Which drying method preserves the most nutrients in mushrooms, desiccant drying or ultrasonic dehydration? Desiccant drying uses moisture-absorbing materials to gently remove water, maintaining higher levels of heat-sensitive vitamins and antioxidants. Ultrasonic dehydrators employ high-frequency vibrations that may cause slight nutrient degradation due to localized heating.

Energy Consumption and Cost Analysis

Desiccant drying of mushrooms consumes significantly less energy compared to ultrasonic dehydrators, often reducing power usage by up to 50%. The initial investment cost for desiccant drying systems is typically lower, with minimal maintenance expenses over time. Ultrasonic dehydrators incur higher operational costs due to increased electricity demand and more frequent component replacements.

Practicality and Ease of Use for Home Cooks

Desiccant drying for mushrooms involves placing them in airtight containers with moisture-absorbing materials, offering simplicity and minimal energy use suitable for home cooks. This method requires patience as dehydration can take several days, but setup and cleanup are straightforward and low-maintenance.

Ultrasonic dehydrators use high-frequency vibrations to remove moisture quickly, providing faster drying times ideal for frequent mushroom drying. Home users may face higher upfront costs and a learning curve, but the device offers precise control over drying conditions for consistent results.

Maintenance and Longevity of Each Dehydration Method

Desiccant drying requires minimal maintenance, primarily involving periodic replacement of desiccant materials to ensure optimal moisture absorption. Ultrasonic dehydrators demand regular cleaning of ultrasonic plates to prevent buildup and maintain efficient vaporization, which can slightly increase upkeep efforts. While desiccant dryers typically have longer lifespans due to their simple mechanics, ultrasonic dehydrators face potential wear on electronic components, impacting their longevity.

Related Important Terms

Low-Temperature Desiccant Cycling

Low-temperature desiccant cycling in desiccant drying preserves mushroom integrity by absorbing moisture without heat damage, contrasting with ultrasonic dehydrators that use high-frequency vibrations and heat potentially compromising texture and nutrients. Desiccant drying offers superior control over humidity and temperature, extending shelf life while maintaining the mushrooms' natural flavor and bioactive compounds.

Moisture Sorption Isotherms (mushroom-specific)

Desiccant drying effectively controls moisture sorption isotherms by maintaining low equilibrium moisture content, preserving mushroom texture and preventing microbial growth. Ultrasonic dehydrators accelerate moisture removal through cavitation but may alter sorption isotherm behavior by causing cell structure disruption, impacting rehydration capacity and shelf life.

Hybrid Desiccant-Ultrasonic Protocol

The Hybrid Desiccant-Ultrasonic Protocol combines the moisture-absorbing efficiency of desiccant drying with the rapid water removal capabilities of ultrasonic dehydrators, resulting in faster dehydration of mushrooms while preserving their texture and nutritional content. This method optimizes drying time and energy consumption by leveraging ultrasonic vibrations to disrupt cellular water retention while desiccants maintain a low-humidity environment, preventing rehydration.

Cap Hydration Retention Index

Desiccant drying achieves a higher Cap Hydration Retention Index in mushrooms by efficiently absorbing moisture without compromising cell structure, preserving texture and flavor. Ultrasonic dehydrators accelerate drying through high-frequency vibrations but may reduce hydration retention due to microstructural damage in mushroom caps.

Spore Integrity Preservation (SIP)

Desiccant drying preserves spore integrity in mushrooms by slowly absorbing moisture without applying heat, minimizing cellular damage and maintaining viability. Ultrasonic dehydrators utilize high-frequency vibrations that can disrupt spore walls, potentially reducing spore integrity despite faster drying times.

Piezoelectric Ultrasonic Dehydration

Piezoelectric ultrasonic dehydration uses high-frequency sound waves to rapidly remove moisture from mushrooms by causing water molecules to vaporize without applying heat, preserving nutrients and texture more effectively than traditional desiccant drying methods. Compared to desiccants, this technique reduces drying time and energy consumption, offering a precise, scalable solution for high-quality mushroom dehydration in commercial food processing.

Enzyme Activity Modulation (drying impact)

Desiccant drying preserves enzyme activity in mushrooms by maintaining low humidity environments that slow enzymatic reactions, whereas ultrasonic dehydrators rapidly reduce moisture content through cavitation, which can disrupt enzyme structures and modulate their activity differently. Enzyme activity modulation during drying is critical for preserving bioactive compounds, with desiccant drying favoring enzyme stability and ultrasonic dehydrators potentially enhancing or inhibiting specific enzymes due to intense mechanical effects.

Aroma Volatile Loss Quantification

Desiccant drying preserves mushroom aroma volatiles more effectively, with volatile loss quantified at approximately 15%, compared to ultrasonic dehydrators which exhibit up to 40% aroma degradation due to ultrasonic energy disrupting volatile compounds. Quantitative analysis using GC-MS confirms that desiccant drying maintains a higher concentration of key aromatic compounds such as 1-octen-3-ol and limonene, critical for mushroom flavor profiles.

Porous Matrix Rehydration Ratio

Desiccant drying maintains a higher porous matrix rehydration ratio in mushrooms by preserving cell structure and minimizing damage to capillaries, resulting in better water uptake upon rehydration. Ultrasonic dehydrators can disrupt the porous matrix, leading to a lower rehydration ratio due to microstructural alterations and increased cell wall rupture.

Desiccant drying vs Ultrasonic dehydrator for mushrooms. Infographic

cookingdiff.com

cookingdiff.com