Stainless steel dehydrating trays offer superior durability and resistance to rust compared to plastic trays, ensuring a longer lifespan for pet food preparation. They provide better heat distribution, resulting in more evenly dehydrated pet treats that retain optimal nutritional value. Plastic trays, while lighter and often more affordable, may warp under high temperatures and retain odors, making stainless steel a more hygienic and reliable choice for cooking pet food.

Table of Comparison

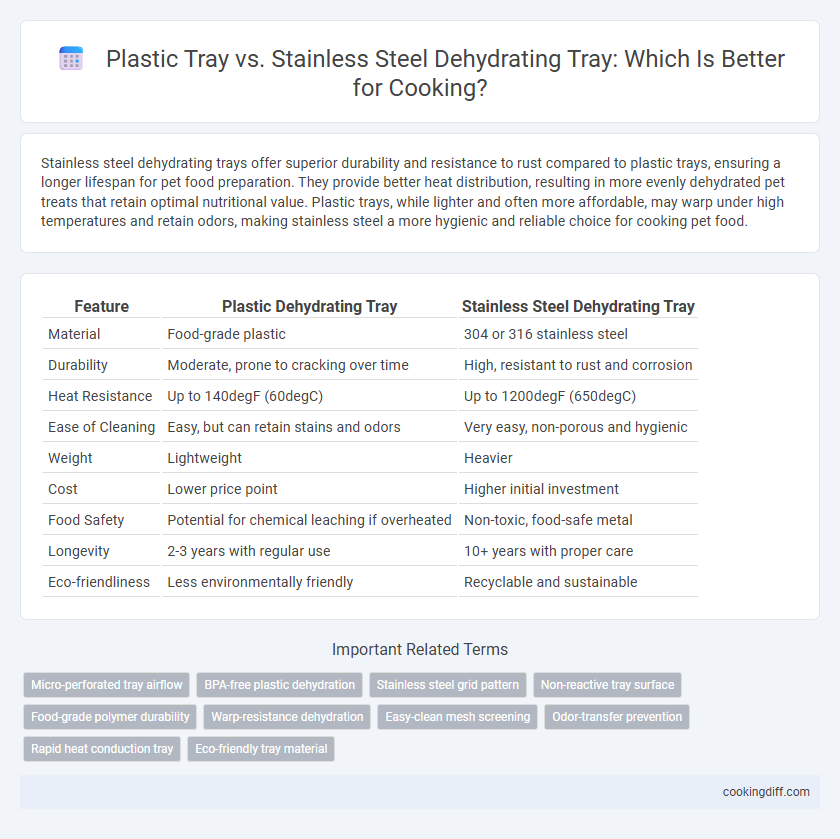

| Feature | Plastic Dehydrating Tray | Stainless Steel Dehydrating Tray |

|---|---|---|

| Material | Food-grade plastic | 304 or 316 stainless steel |

| Durability | Moderate, prone to cracking over time | High, resistant to rust and corrosion |

| Heat Resistance | Up to 140degF (60degC) | Up to 1200degF (650degC) |

| Ease of Cleaning | Easy, but can retain stains and odors | Very easy, non-porous and hygienic |

| Weight | Lightweight | Heavier |

| Cost | Lower price point | Higher initial investment |

| Food Safety | Potential for chemical leaching if overheated | Non-toxic, food-safe metal |

| Longevity | 2-3 years with regular use | 10+ years with proper care |

| Eco-friendliness | Less environmentally friendly | Recyclable and sustainable |

Introduction to Dehydrating Trays: Plastic vs Stainless Steel

Dehydrating trays play a crucial role in the drying process by allowing airflow around the food to remove moisture efficiently. Plastic trays are lightweight and resist corrosion but may retain odors and stain over time, while stainless steel trays offer durability, easy cleaning, and non-reactive surfaces ideal for food safety. Choosing between plastic and stainless steel trays depends on factors like budget, maintenance preference, and desired lifespan for optimal dehydrating results.

Material Composition: What Sets Plastic and Stainless Steel Apart

Plastic trays for dehydrating are typically made from food-grade polypropylene, offering lightweight and cost-effective options ideal for low-temperature drying. Stainless steel trays consist of durable, corrosion-resistant alloys like 304 stainless steel, well-suited for high-heat applications and long-term use.

- Plastic Composition - Made from BPA-free polypropylene, plastic trays ensure safe food contact but may warp at higher temperatures above 120degF (49degC).

- Stainless Steel Durability - Constructed from 18/8 or 304 stainless steel, these trays resist rust and withstand temperatures exceeding 400degF (204degC) without deformation.

- Material Impact on Food Safety - Stainless steel trays do not leach chemicals during dehydration, providing a cleaner drying surface compared to some plastics.

Heat Distribution Efficiency in Dehydrating Trays

Stainless steel dehydrating trays offer superior heat distribution efficiency compared to plastic trays, ensuring even drying of food. Plastic trays tend to have uneven heat conduction, which can result in inconsistent dehydration and longer drying times.

- Stainless steel heat conductivity - Metal's high thermal conductivity promotes uniform heat spread across the tray surface.

- Plastic thermal insulation - Plastic acts as an insulator, limiting heat transfer and creating hotspots or cold areas.

- Durability under heat - Stainless steel maintains structural integrity during extended heating, unlike some plastics that may warp or degrade.

Choosing stainless steel dehydrating trays enhances efficiency and food quality by optimizing heat distribution during dehydration.

Durability and Longevity: Which Tray Lasts Longer?

Which tray offers superior durability and longevity for dehydrating--plastic or stainless steel? Stainless steel dehydrating trays resist warping, cracking, and staining, providing a longer lifespan under high heat conditions. Plastic trays, while lightweight and cost-effective, tend to degrade faster due to heat exposure and may absorb odors or stains over time.

Food Safety and Chemical Concerns

Stainless steel dehydrating trays are preferred for cooking due to their non-porous surface that resists bacteria buildup and chemical leaching. Plastic trays may release harmful chemicals when exposed to high temperatures, raising food safety concerns.

- Food Safety - Stainless steel trays prevent contamination by resisting microbial growth and do not absorb food odors or residues.

- Chemical Concerns - Plastic trays can leach BPA or phthalates into food during dehydration, especially at elevated temperatures.

- Durability - Stainless steel trays withstand repeated heating without degrading, ensuring long-term safe food preparation.

Cleaning and Maintenance Requirements

| Plastic Tray | Lightweight and dishwasher safe, but prone to staining and retaining odors. Requires thorough hand washing with mild detergent to prevent bacterial buildup. Avoids harsh scrubbing to maintain surface integrity and extend usability. |

| Stainless Steel Tray | Durable and resistant to stains and odors, compatible with dishwasher cleaning. Easier to sanitize with boiling water or strong detergents, reducing bacterial risks. Requires occasional polishing to prevent water spots and maintain shine. |

Impact on Food Flavor and Quality

Plastic trays for dehydrating tend to absorb odors and flavors over time, which can subtly alter the taste of foods, especially delicate fruits or herbs. Their porous nature may also impact moisture retention, potentially affecting the texture and overall quality of the dehydrated products.

Stainless steel dehydrating trays offer a non-reactive, odor-free surface that preserves the natural flavor and integrity of the food. They provide even heat distribution and are easier to clean, ensuring consistent quality and reducing the risk of cross-contamination between batches.

Cost Comparison: Plastic vs Stainless Steel Trays

Plastic dehydrating trays generally cost significantly less than stainless steel trays, making them a budget-friendly option for those new to dehydrating or on a tight budget. However, plastic trays may wear out faster due to heat exposure and are less resistant to staining or odor retention compared to stainless steel.

Stainless steel trays, while more expensive upfront, offer superior durability, corrosion resistance, and easier cleaning, which can result in cost savings over time. Their longevity and ability to maintain food safety standards often justify the higher initial investment for frequent or professional users.

Best Uses: Which Tray Suits Different Dehydrating Needs

Plastic trays are ideal for dehydrating lightweight, non-acidic foods like herbs and fruits due to their lightweight and affordable construction. Stainless steel trays excel in handling high-temperature dehydrating tasks and are perfect for meats and jerky, offering durability and easy cleaning. Choosing between plastic and stainless steel depends on the food type, dehydration temperature, and desired longevity of the tray.

Related Important Terms

Micro-perforated tray airflow

Micro-perforated stainless steel dehydrating trays offer superior airflow and durability compared to plastic trays, enabling more even and efficient drying of foods. The metal's heat conductivity combined with precise micro-perforations ensures optimal moisture evaporation and reduces drying time in dehydrators.

BPA-free plastic dehydration

BPA-free plastic dehydrating trays offer a lightweight, non-reactive alternative to stainless steel trays, ensuring no harmful chemicals leach into food during dehydration. Stainless steel trays provide superior durability and heat distribution but can be heavier and more expensive, whereas BPA-free plastic trays remain affordable and safe for long-term use.

Stainless steel grid pattern

Stainless steel dehydrating trays feature a precise grid pattern that promotes even air circulation and consistent drying, reducing the risk of unevenly dehydrated food. Their durable, rust-resistant construction ensures longevity and easy cleaning compared to plastic trays, which may warp or retain odors over time.

Non-reactive tray surface

Stainless steel dehydrating trays offer a non-reactive surface that prevents flavor contamination and chemical leaching during food dehydration, ensuring preserved taste and safety. In contrast, many plastic trays can absorb odors and react with acidic or hot foods, potentially affecting food quality and safety.

Food-grade polymer durability

Plastic dehydrating trays made from food-grade polymers offer excellent durability due to their resistance to cracking, warping, and corrosion during extended exposure to heat and moisture. In contrast, stainless steel trays provide superior structural strength and longevity but may experience surface discoloration and potential corrosion without proper maintenance.

Warp-resistance dehydration

Stainless steel dehydrating trays offer superior warp resistance during high-temperature dehydration compared to plastic trays, maintaining structural integrity and ensuring even airflow. Plastic trays are prone to warping and melting under prolonged heat, which can compromise drying efficiency and food safety.

Easy-clean mesh screening

Plastic dehydrating trays with easy-clean mesh screens prevent food particles from sticking and simplify washing, making them ideal for low-maintenance use. Stainless steel dehydrating trays offer durability and corrosion resistance but require more effort to clean fine mesh screens thoroughly.

Odor-transfer prevention

Stainless steel dehydrating trays are highly effective in preventing odor transfer due to their non-porous surface, which resists absorption of strong food smells. In contrast, plastic trays tend to retain odors over time, potentially affecting the flavor and aroma of subsequent dehydrated foods.

Rapid heat conduction tray

Stainless steel dehydrating trays offer superior rapid heat conduction compared to plastic trays, enhancing even drying and reducing overall dehydration time. Their durability and ability to withstand higher temperatures make them ideal for efficient and consistent food dehydration.

Plastic tray vs Stainless steel dehydrating tray for cooking. Infographic

cookingdiff.com

cookingdiff.com