Hot air drying effectively removes moisture from vegetable chips by circulating heated air, resulting in a crisp texture but can cause nutrient loss and color degradation due to high temperatures. Vacuum drying operates at lower pressures and temperatures, preserving more nutrients, flavors, and natural colors while producing evenly dried chips with less oxidative damage. Choosing between these methods depends on balancing quality retention with drying efficiency and energy consumption.

Table of Comparison

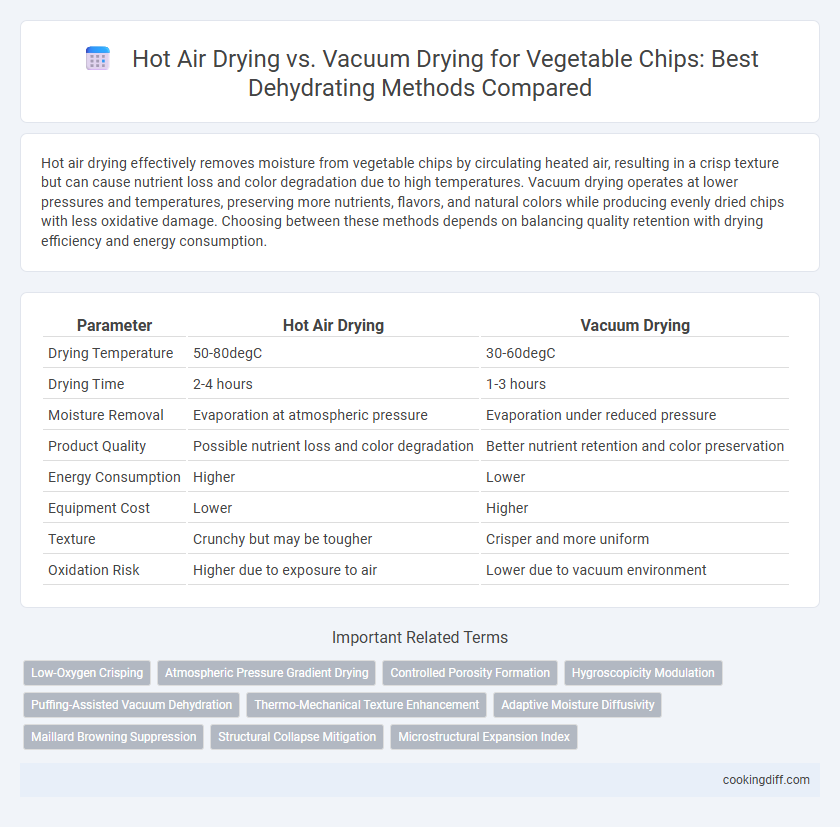

| Parameter | Hot Air Drying | Vacuum Drying |

|---|---|---|

| Drying Temperature | 50-80degC | 30-60degC |

| Drying Time | 2-4 hours | 1-3 hours |

| Moisture Removal | Evaporation at atmospheric pressure | Evaporation under reduced pressure |

| Product Quality | Possible nutrient loss and color degradation | Better nutrient retention and color preservation |

| Energy Consumption | Higher | Lower |

| Equipment Cost | Lower | Higher |

| Texture | Crunchy but may be tougher | Crisper and more uniform |

| Oxidation Risk | Higher due to exposure to air | Lower due to vacuum environment |

Introduction to Vegetable Chip Dehydration Methods

Hot air drying is a common method for dehydrating vegetable chips, utilizing heated air to remove moisture efficiently while maintaining crispness. Vacuum drying operates at lower temperatures and reduced pressure, preserving color, flavor, and nutritional value by minimizing oxidation. Both methods offer unique advantages depending on the desired texture and quality of the final vegetable chip product.

Hot Air Drying: Process Overview and Principles

Hot air drying removes moisture from vegetable chips by circulating heated air around the product, enhancing evaporation rates through high temperature and airflow. This method relies on heat transfer via convection, effectively reducing water content while maintaining the chip's texture and color. The process parameters, such as air temperature, velocity, and humidity, are crucial for optimizing drying efficiency and product quality.

Vacuum Drying: Process Overview and Principles

Vacuum drying involves removing moisture from vegetable chips by lowering the pressure around the product, which reduces the boiling point of water and allows drying at lower temperatures. This method preserves the nutritional content, color, and texture of vegetable chips better than hot air drying.

The process uses a vacuum chamber where heat is applied under reduced pressure, leading to efficient moisture evaporation without exposing chips to high thermal stress. The controlled environment minimizes oxidation and enzymatic reactions, resulting in higher-quality, crispier vegetable chips.

Energy Efficiency: Hot Air vs Vacuum Drying

Hot air drying for vegetable chips typically consumes more energy due to prolonged drying times and higher operating temperatures, which increase electricity usage. Vacuum drying operates at lower temperatures and reduced pressure, significantly cutting energy consumption while preserving nutrients and texture.

Energy efficiency in vacuum drying results from faster moisture removal under low pressure, lowering thermal degradation and operational costs. Hot air drying often demands continuous air circulation and heating, making it less energy-efficient compared to vacuum drying in large-scale production.

Nutritional Retention in Hot Air and Vacuum Dried Chips

How does nutritional retention compare between hot air drying and vacuum drying for vegetable chips? Vacuum drying preserves higher levels of vitamins and antioxidants in vegetable chips due to lower temperature exposure and reduced oxidation. Hot air drying often results in significant nutrient loss because of prolonged heat and oxygen contact during the drying process.

Texture and Crunch Comparison

Hot air drying produces vegetable chips with a crisp outer layer but often results in a slightly tougher texture due to prolonged exposure to high temperatures. Vacuum drying preserves the natural cell structure better, yielding chips with a lighter, more delicate crunch.

The reduced pressure in vacuum drying minimizes oxidation, maintaining vibrant color and enhancing texture integrity in vegetable chips. Hot air drying can cause uneven moisture removal, leading to inconsistent crunchiness. Vacuum drying consistently delivers a uniform, airy texture that enhances sensory appeal.

Color and Appearance Differences

Hot air drying often results in vegetable chips with a darker, browned appearance due to higher exposure to oxygen and heat, which can cause caramelization and Maillard reactions. Vacuum drying preserves the natural color and brightness of vegetable chips by removing moisture at lower temperatures and reducing oxidative damage.

- Color retention - Vacuum drying maintains vibrant colors by minimizing oxidation compared to hot air drying.

- Surface appearance - Hot air dried chips tend to have a more uneven, rough texture due to prolonged heat exposure.

- Visual appeal - Vacuum drying produces smoother, visually appealing chips with less browning or discoloration.

Flavor Preservation and Changes

Hot air drying often leads to flavor degradation in vegetable chips due to prolonged exposure to high temperatures and oxygen. Vacuum drying better preserves the natural flavors by reducing oxidation and drying at lower temperatures.

- Oxidation Impact - Hot air drying exposes vegetables to oxygen, causing loss of volatile flavor compounds.

- Temperature Sensitivity - Vacuum drying uses lower temperatures, minimizing thermal damage to delicate flavor molecules.

- Flavor Retention - Vacuum drying maintains a fresher, more natural taste profile in vegetable chips compared to hot air drying.

Vacuum drying is preferred for superior flavor preservation in dehydrated vegetable chips.

Production Cost Analysis: Hot Air vs Vacuum Drying

| Drying Method | Energy Consumption (kWh/kg) | Equipment Cost (USD) | Operating Cost (USD/ton) |

|---|---|---|---|

| Hot Air Drying | 1.2 | 50,000 | 150 |

| Vacuum Drying | 2.5 | 120,000 | 300 |

Related Important Terms

Low-Oxygen Crisping

Vacuum drying preserves the natural color and nutrients of vegetable chips by reducing oxygen exposure, resulting in a crisp texture without oxidative damage. Hot air drying subjects chips to higher oxygen levels and temperatures, which can lead to nutrient loss and less crispness compared to vacuum drying's low-oxygen environment.

Atmospheric Pressure Gradient Drying

Hot air drying utilizes atmospheric pressure gradient drying, promoting moisture evaporation from vegetable chips through forced convection at ambient pressure, which speeds up drying but may cause nutrient loss and shrinkage. Vacuum drying lowers the pressure around the chips, reducing the boiling point of water for gentler dehydration that preserves flavor and nutrients but requires longer processing times and higher energy costs.

Controlled Porosity Formation

Hot air drying promotes uniform moisture removal, resulting in moderate porosity that maintains crispness in vegetable chips, while vacuum drying enhances controlled porosity formation by reducing oxidation and preserving cellular structure through lower pressure and temperature conditions. This controlled porosity in vacuum drying improves texture and shelf life, optimizing the quality of dehydrated vegetable chips.

Hygroscopicity Modulation

Hot air drying maintains higher hygroscopicity in vegetable chips due to prolonged exposure to moisture and oxygen, resulting in increased susceptibility to moisture absorption during storage. Vacuum drying reduces hygroscopicity by minimizing oxygen contact and lowering drying temperature, preserving the structural integrity and extending the shelf life of dehydrated vegetable chips.

Puffing-Assisted Vacuum Dehydration

Puffing-assisted vacuum dehydration enhances the texture and retains nutrients of vegetable chips more effectively than hot air drying by combining rapid moisture removal under low pressure with puffing that creates a porous structure. This method reduces drying time and preserves color, flavor, and crispiness, offering superior quality compared to conventional hot air drying.

Thermo-Mechanical Texture Enhancement

Hot air drying enhances vegetable chips' texture through controlled dehydration and Maillard reactions, resulting in a crispy, golden surface but may cause structural shrinkage due to prolonged heat exposure. Vacuum drying preserves the microstructure by lowering boiling points, minimizing thermal damage, and producing a uniformly porous, crisp texture with improved mechanical integrity and reduced nutrient loss.

Adaptive Moisture Diffusivity

Hot air drying of vegetable chips often exhibits variable moisture diffusivity due to temperature gradients, whereas vacuum drying ensures more uniform adaptive moisture diffusivity by reducing pressure and enabling lower temperature evaporation. Enhanced control of adaptive moisture diffusivity in vacuum drying preserves chip texture and nutritional quality more effectively than the conventional hot air method.

Maillard Browning Suppression

Vacuum drying significantly suppresses Maillard browning in vegetable chips by reducing oxygen exposure and operating at lower temperatures compared to hot air drying, which promotes browning through higher heat and oxygen contact. This leads to better color retention and less nutrient degradation in vacuum-dried vegetable chips.

Structural Collapse Mitigation

Hot air drying for vegetable chips often risks structural collapse due to uneven moisture removal and prolonged exposure to high temperatures, compromising texture and crispiness. Vacuum drying mitigates structural collapse by enabling lower drying temperatures and faster moisture evaporation under reduced pressure, preserving cellular integrity and maintaining chip crispness.

Hot air drying vs Vacuum drying for vegetable chips. Infographic

cookingdiff.com

cookingdiff.com