Traditional rack drying relies on natural air circulation and ambient conditions, resulting in inconsistent moisture removal and longer drying times. Smart dehydrators use precise temperature controls and airflow optimization to ensure even drying, preserving flavor and nutrients more effectively. This technology reduces processing time and energy consumption, making it a more efficient and reliable option for dehydrating food.

Table of Comparison

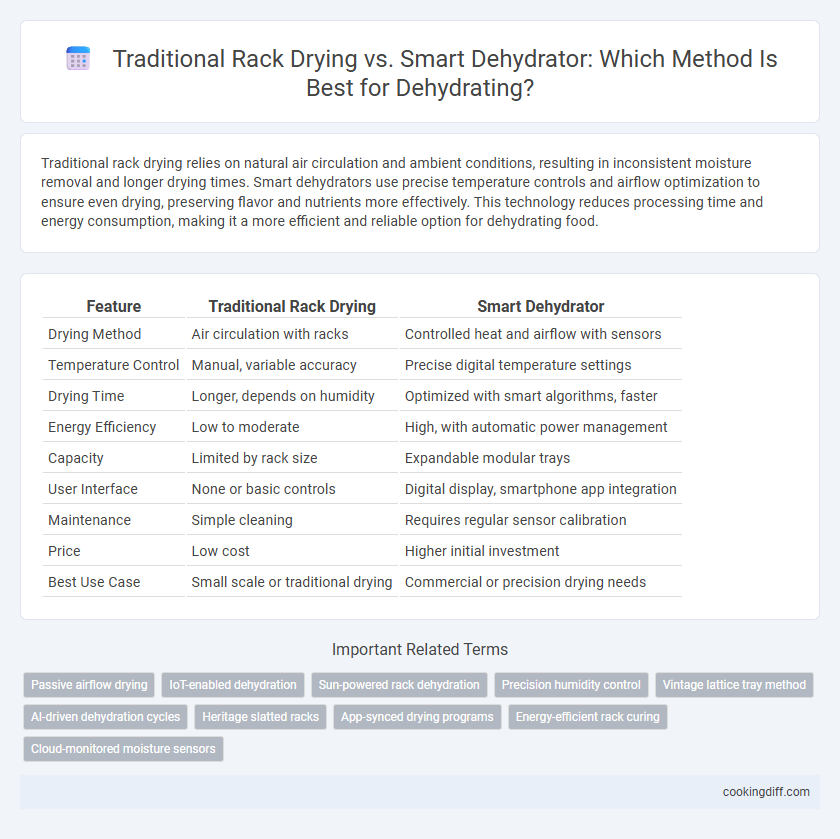

| Feature | Traditional Rack Drying | Smart Dehydrator |

|---|---|---|

| Drying Method | Air circulation with racks | Controlled heat and airflow with sensors |

| Temperature Control | Manual, variable accuracy | Precise digital temperature settings |

| Drying Time | Longer, depends on humidity | Optimized with smart algorithms, faster |

| Energy Efficiency | Low to moderate | High, with automatic power management |

| Capacity | Limited by rack size | Expandable modular trays |

| User Interface | None or basic controls | Digital display, smartphone app integration |

| Maintenance | Simple cleaning | Requires regular sensor calibration |

| Price | Low cost | Higher initial investment |

| Best Use Case | Small scale or traditional drying | Commercial or precision drying needs |

Introduction to Food Dehydration Methods

Traditional rack drying relies on natural air circulation and ambient temperatures to remove moisture from food, which can be time-consuming and weather-dependent. Smart dehydrators use precise temperature controls and airflow management to ensure consistent and efficient dehydration, preserving nutrients and flavor. These modern devices often include programmable settings and timers to optimize drying cycles for different types of foods, enhancing convenience and reliability.

Overview of Traditional Rack Drying

Traditional rack drying employs open air circulation and natural drying processes to remove moisture from foods, often relying on ambient temperature and airflow. This method is energy-efficient but typically slower and less consistent compared to modern alternatives.

- Simple construction - Traditional racks are made from basic materials like wood or metal, allowing for easy assembly and low maintenance.

- Low operational cost - It requires minimal energy input, making it cost-effective for small-scale or home use.

- Environmental dependence - Drying efficiency depends on weather conditions, temperature, and humidity levels, leading to variable results.

Understanding Smart Food Dehydrators

| Smart food dehydrators utilize precise temperature control and humidity sensors to optimize the drying process of fruits, vegetables, and meats. |

| Unlike traditional rack drying, which relies on ambient conditions and airflow, smart dehydrators ensure consistent results by adjusting settings automatically. |

| These advanced features reduce dehydration time and preserve nutritional content more effectively, making smart dehydrators a superior choice for food preservation. |

Efficiency Comparison: Rack Drying vs. Smart Dehydrators

Traditional rack drying relies on natural air circulation and ambient temperature, making it slower and less consistent for dehydrating foods. Smart dehydrators use precise temperature controls and airflow technology, significantly improving drying speed and product quality.

- Energy Efficiency - Smart dehydrators consume less energy due to optimized heating elements and fan systems compared to passive rack drying.

- Drying Time - Rack drying can take several days, whereas smart dehydrators typically complete the process within hours.

- Consistency - Smart dehydrators ensure uniform dehydration by maintaining stable temperature and humidity levels, unlike variable outdoor conditions in rack drying.

Choosing a smart dehydrator enhances overall efficiency and product consistency in food dehydration processes.

Energy Usage and Environmental Impact

Traditional rack drying methods rely on ambient air and natural sunlight, resulting in minimal energy consumption but are highly dependent on weather conditions, which can lead to inconsistent drying times and potential crop spoilage. This natural process produces zero emissions, making it environmentally friendly but less efficient for large-scale or time-sensitive operations.

Smart dehydrators use controlled temperature and airflow powered by electricity, increasing energy usage compared to traditional methods but offering precise and consistent dehydration regardless of weather. These devices often incorporate energy-efficient technologies and renewable energy options, reducing their overall environmental impact while maximizing productivity.

Flavor and Nutrient Retention Differences

Traditional rack drying often results in uneven heat distribution, causing a greater loss of flavor and nutrients in dehydrated foods. Smart dehydrators utilize precise temperature control and airflow technology to better preserve the natural taste and nutritional content.

- Flavor Retention - Smart dehydrators maintain consistent temperatures that help retain the original flavor profiles more effectively than traditional rack drying.

- Nutrient Preservation - Advanced sensors in smart dehydrators reduce exposure to excessive heat, preserving sensitive vitamins and antioxidants better.

- Drying Uniformity - Even airflow in smart dehydrators ensures uniform dehydration, minimizing nutrient degradation that occurs with uneven drying on traditional racks.

Time Requirements for Dehydration Processes

Traditional rack drying typically requires 24 to 72 hours depending on the humidity and temperature conditions, making it a lengthy process. Smart dehydrators use precise temperature controls and airflow technologies to reduce dehydration time to 6 to 12 hours. This optimization enhances efficiency and preserves nutrient content more effectively than conventional methods.

Safety and Hygiene Considerations

How do safety and hygiene differ between traditional rack drying and smart dehydrators? Traditional rack drying often exposes food to contaminants such as dust, insects, and bacteria due to open air exposure. Smart dehydrators provide controlled temperature and enclosed environments that significantly reduce contamination risks and promote safer food preservation.

Cost Analysis: Initial Investment and Long-Term Savings

Traditional rack drying requires a low initial investment but involves higher ongoing costs due to extended drying times and energy inefficiency. Smart dehydrators demand a higher upfront cost but optimize energy use and reduce labor expenses over time.

While traditional racks depend on manual monitoring and longer drying cycles that drive up electricity bills and product loss, smart dehydrators leverage precise temperature control and airflow for consistent results. This efficiency translates to significant long-term savings, especially for commercial operations processing large volumes. Analysis shows that despite the initial high cost, smart dehydrators deliver better return on investment through reduced energy consumption and improved product quality.

Related Important Terms

Passive airflow drying

Traditional rack drying relies on passive airflow to naturally remove moisture, but this method often results in uneven drying and longer processing times due to limited air circulation. Smart dehydrators enhance passive airflow with built-in fans and sensors that optimize temperature and humidity, ensuring consistent dehydration while preserving nutritional quality and reducing energy consumption.

IoT-enabled dehydration

IoT-enabled smart dehydrators offer precise temperature and humidity control through real-time sensor data, optimizing dehydration efficiency compared to traditional rack drying methods that rely on manual monitoring and uneven airflow. These smart devices integrate with mobile apps to provide remote monitoring, automated alerts, and energy-saving features, significantly improving food preservation quality and reducing spoilage.

Sun-powered rack dehydration

Sun-powered rack dehydration utilizes solar energy to naturally remove moisture from food, preserving nutrients and flavor without electricity consumption, making it an eco-friendly option. Unlike smart dehydrators that rely on automated temperature control and energy use, traditional racks depend on optimal sunlight and ventilation, resulting in longer drying times and variable outcomes.

Precision humidity control

Traditional rack drying lacks precision humidity control, often leading to uneven dehydration and potential spoilage, while smart dehydrators utilize advanced sensors and automated systems to maintain optimal humidity levels, ensuring consistent drying quality and preserving nutritional value. Enhanced humidity regulation in smart dehydrators reduces drying time and energy consumption compared to conventional methods.

Vintage lattice tray method

The vintage lattice tray method in traditional rack drying provides a natural airflow that aids dehydration but often leads to uneven drying and longer processing times. In contrast, smart dehydrators use precise temperature control and airflow technology to ensure consistent moisture removal, enhancing efficiency and preserving nutrient quality.

AI-driven dehydration cycles

Smart dehydrators utilize AI-driven dehydration cycles that optimize temperature and airflow for uniform drying, reducing nutrient loss and energy consumption compared to traditional rack drying methods. Traditional rack drying often involves manual monitoring and inconsistent heat distribution, leading to uneven dehydration and prolonged drying times.

Heritage slatted racks

Heritage slatted racks in traditional rack drying provide natural airflow and gentle dehydration, preserving texture and flavor but requiring more manual monitoring and longer drying times. In contrast, smart dehydrators automate temperature and humidity control, enhancing efficiency and consistency while reducing labor and preserving nutritional quality.

App-synced drying programs

Traditional rack drying relies on manual monitoring and inconsistent temperature control, often resulting in uneven dehydration and longer drying times. Smart dehydrators with app-synced drying programs optimize drying cycles by precisely regulating temperature and humidity, ensuring consistent results and energy efficiency.

Energy-efficient rack curing

Traditional rack drying relies on passive airflow and ambient conditions, often leading to longer drying times and higher energy consumption due to inconsistent temperature control. Smart dehydrators utilize precise temperature regulation and energy-efficient components, significantly reducing energy usage while ensuring uniform dehydration and preserving product quality.

Traditional rack drying vs Smart dehydrator for dehydrating. Infographic

cookingdiff.com

cookingdiff.com