Manual dehydration of fruit leather requires constant monitoring and adjusting temperature and time based on visual cues, often leading to inconsistent texture and moisture levels. Sensor-controlled dehydration uses precise humidity and temperature sensors to maintain optimal drying conditions, ensuring uniform moisture removal and better retention of flavor and nutrients. This technology minimizes human error and reduces drying time, resulting in higher quality and more consistent fruit leather batches.

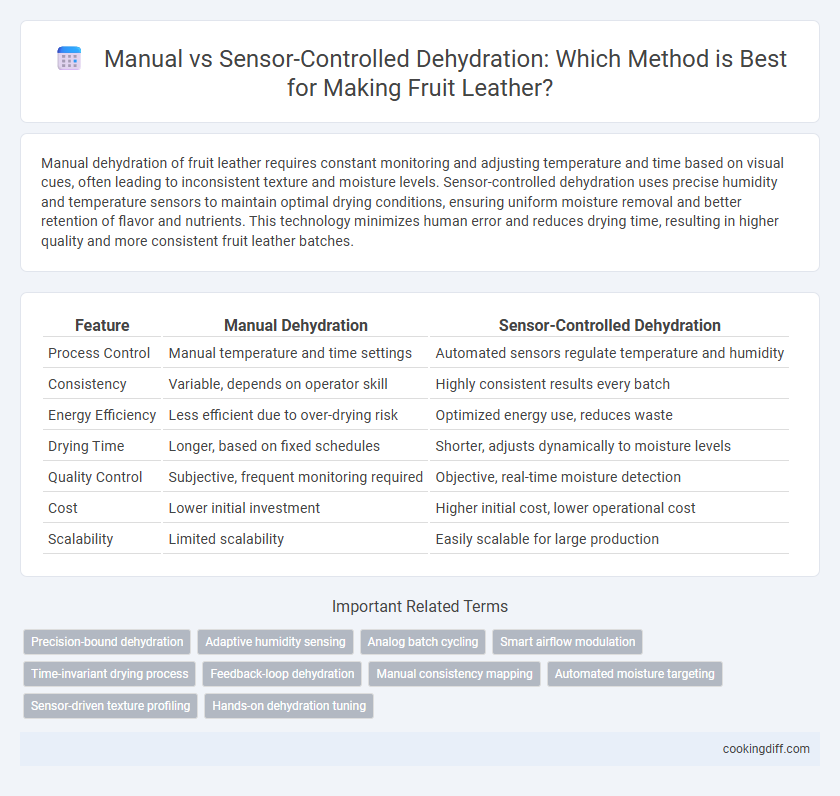

Table of Comparison

| Feature | Manual Dehydration | Sensor-Controlled Dehydration |

|---|---|---|

| Process Control | Manual temperature and time settings | Automated sensors regulate temperature and humidity |

| Consistency | Variable, depends on operator skill | Highly consistent results every batch |

| Energy Efficiency | Less efficient due to over-drying risk | Optimized energy use, reduces waste |

| Drying Time | Longer, based on fixed schedules | Shorter, adjusts dynamically to moisture levels |

| Quality Control | Subjective, frequent monitoring required | Objective, real-time moisture detection |

| Cost | Lower initial investment | Higher initial cost, lower operational cost |

| Scalability | Limited scalability | Easily scalable for large production |

Introduction to Fruit Leather Dehydration Methods

Fruit leather dehydration can be achieved through manual methods or sensor-controlled systems, each influencing drying consistency and product quality. Understanding these methods helps optimize texture and nutritional retention in fruit leather production.

- Manual Dehydration - Relies on operator timing and temperature control to dry fruit leather, often resulting in variable moisture levels.

- Sensor-Controlled Dehydration - Utilizes digital sensors to monitor humidity and temperature, ensuring uniform drying and consistent texture.

- Impact on Quality - Sensor-controlled methods generally enhance nutrient preservation and reduce drying errors compared to manual techniques.

Overview: Manual vs Sensor-Controlled Dehydrators

Manual dehydration requires constant temperature and time adjustments by the user, which can lead to inconsistent drying results for fruit leather. Sensor-controlled dehydration uses built-in sensors to monitor and automatically adjust conditions, enhancing precision and product quality.

- Manual Dehydrators - Depend on user input to regulate temperature and drying time, increasing risk of uneven dehydration.

- Sensor-Controlled Dehydrators - Utilize sensory feedback to maintain optimal humidity and temperature levels throughout the drying process.

- Fruit Leather Quality - Sensor control generally produces more uniform texture and moisture content, resulting in better preservation.

Precision of Temperature and Timing

Manual dehydration requires constant monitoring and adjustment to maintain the ideal temperature and timing for fruit leather, often leading to inconsistent results. Sensor-controlled dehydration uses precise sensors to regulate temperature and timing automatically, ensuring uniform drying and optimal texture. This technology reduces the risk of over-drying or under-drying, enhancing the quality and shelf life of fruit leather.

Uniformity and Consistency of Results

Manual dehydration of fruit leather often results in uneven drying due to inconsistent temperature and airflow control, leading to variable texture and moisture levels. Sensor-controlled dehydration uses advanced technology to monitor humidity and temperature, ensuring uniform drying and consistent product quality. This precision reduces the risk of over-drying or under-drying, enhancing the overall shelf life and taste of the fruit leather.

Control and Customization in Dehydrating

Manual dehydration offers basic control through time and temperature settings but requires constant monitoring to achieve desired results. Sensor-controlled dehydration provides precise, real-time adjustments ensuring consistent moisture levels and enhanced customization for fruit leather texture.

- Manual Control - Users set fixed dehydration times and temperatures, relying on experience to judge dryness.

- Sensor Feedback - Sensors detect moisture content and automatically adjust conditions for optimal dehydration.

- Customization Level - Sensor-controlled units enable tailored dehydration profiles for varying fruit types and thicknesses.

Sensor-controlled dehydration improves consistency and reduces guesswork in making perfect fruit leather.

Energy Efficiency and Power Consumption

Which method between manual dehydration and sensor-controlled dehydration offers better energy efficiency for fruit leather production? Manual dehydration often consumes more power due to continuous operation without feedback, leading to higher energy costs. Sensor-controlled dehydration optimizes power consumption by adjusting drying time and temperature based on moisture levels, resulting in significant energy savings.

Impact on Fruit Leather Texture and Flavor

Manual dehydration often results in uneven texture and inconsistent flavor due to fluctuating temperatures and drying times. Sensor-controlled dehydration maintains precise conditions, producing fruit leather with uniform texture and enhanced natural flavors.

Manual methods risk over-drying or under-drying, which can lead to tough or soggy fruit leather with diminished taste quality. Sensor-controlled systems optimize moisture removal by adjusting in real-time, preserving the fruit's original sweetness and chewiness. This technology improves shelf life and consumer appeal by delivering a consistently high-quality product.

Maintenance and User Effort Required

Manual dehydration of fruit leather requires consistent user intervention to monitor temperature and humidity, leading to higher maintenance efforts and frequent adjustments. Users must regularly check the drying process to prevent uneven dehydration or over-drying.

Sensor-controlled dehydration automates monitoring, reducing the need for constant user input and minimizing maintenance tasks through precise humidity and temperature control. This technology ensures consistent drying quality with less manual oversight and effort.

Cost Comparison and Long-Term Value

| Manual dehydration | Lower initial cost due to simple equipment but higher energy consumption and increased labor time. |

| Sensor-controlled dehydration | Higher upfront investment offset by precise temperature control, reduced energy usage, and consistent product quality, leading to long-term savings. |

| Long-term value | Sensor-controlled systems offer improved efficiency and durability, minimizing waste and maintenance costs, while manual methods may incur higher operational expenses over time. |

Related Important Terms

Precision-bound dehydration

Manual dehydration of fruit leather relies on preset times and temperatures, often leading to inconsistent moisture levels and texture due to lack of real-time monitoring. Sensor-controlled dehydration utilizes humidity and temperature sensors to precisely regulate drying conditions, ensuring uniform moisture removal and optimal fruit leather quality.

Adaptive humidity sensing

Manual dehydration of fruit leather relies on fixed drying times and temperature settings, often leading to inconsistent moisture content and texture. Sensor-controlled dehydration uses adaptive humidity sensing to continuously monitor and adjust drying conditions, ensuring optimal moisture removal and preserving flavor and nutritional quality.

Analog batch cycling

Manual dehydration with analog batch cycling requires consistent monitoring and adjustment to maintain optimal drying conditions, which can lead to uneven moisture levels and extended drying times for fruit leather. Sensor-controlled dehydration automates temperature and humidity regulation, ensuring uniform drying, improved texture, and reduced risk of spoilage in each batch.

Smart airflow modulation

Manual dehydration of fruit leather often results in uneven drying due to inconsistent airflow, while sensor-controlled dehydration employs smart airflow modulation to dynamically adjust air circulation, ensuring uniform moisture removal and preserving optimal texture. This technology enhances energy efficiency and reduces drying time by precisely matching airflow to the fruit leather's changing moisture levels throughout the dehydration process.

Time-invariant drying process

Manual dehydration of fruit leather relies on fixed temperature and time settings that do not adapt during drying, often resulting in inconsistent moisture levels and texture. Sensor-controlled dehydration uses real-time humidity and temperature sensors to adjust drying conditions dynamically, ensuring a uniform, time-invariant drying process that enhances product quality and reduces energy consumption.

Feedback-loop dehydration

Manual dehydration requires frequent user monitoring to adjust temperature and drying time, often leading to inconsistent moisture levels in fruit leather. Sensor-controlled dehydration leverages real-time feedback-loop technology, optimizing humidity and temperature to ensure uniform drying and superior texture preservation.

Manual consistency mapping

Manual dehydration for fruit leather relies on consistent temperature and time settings managed by the operator, ensuring precise control over moisture levels through regular monitoring. Sensor-controlled dehydration automates this process, using real-time humidity and temperature sensors to maintain optimal drying conditions, reducing variability and improving uniformity.

Automated moisture targeting

Sensor-controlled dehydration for fruit leather utilizes automated moisture targeting to precisely regulate drying time and temperature, ensuring consistent texture and optimal moisture retention. Manual dehydration relies on fixed settings and visual checks, often leading to uneven drying and variability in product quality.

Sensor-driven texture profiling

Sensor-controlled dehydration for fruit leather uses real-time texture profiling to precisely adjust drying parameters, ensuring uniform moisture content and preventing over-drying or toughness. This method enhances product quality by maintaining optimal chewiness and flexibility compared to manual dehydration, which relies on fixed time settings and often results in inconsistent texture.

Manual dehydration vs Sensor-controlled dehydration for fruit leather. Infographic

cookingdiff.com

cookingdiff.com