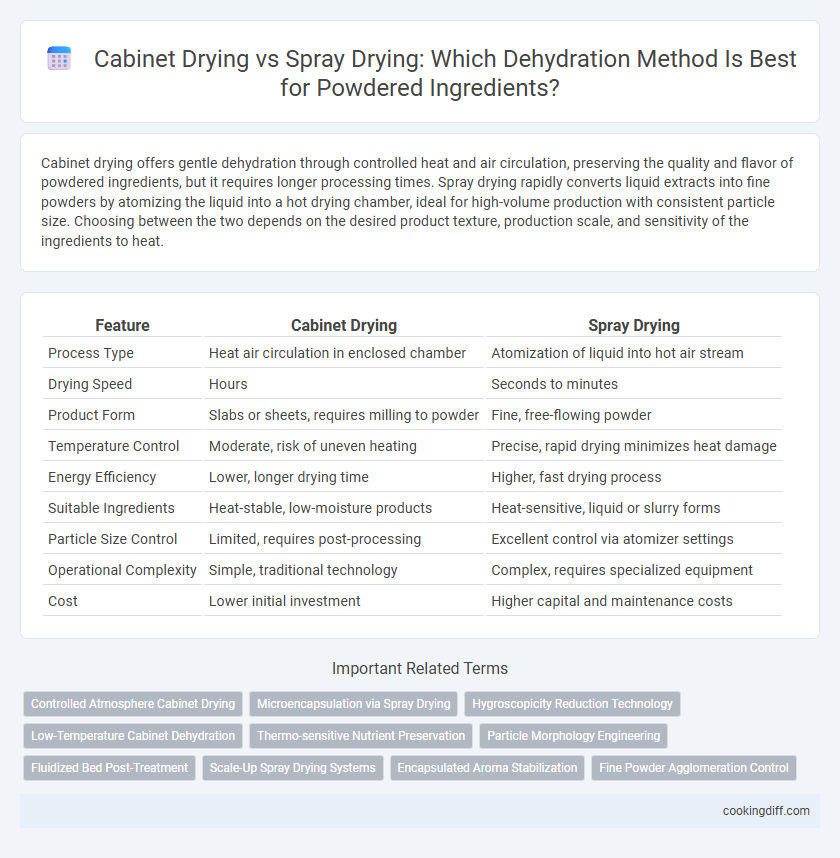

Cabinet drying offers gentle dehydration through controlled heat and air circulation, preserving the quality and flavor of powdered ingredients, but it requires longer processing times. Spray drying rapidly converts liquid extracts into fine powders by atomizing the liquid into a hot drying chamber, ideal for high-volume production with consistent particle size. Choosing between the two depends on the desired product texture, production scale, and sensitivity of the ingredients to heat.

Table of Comparison

| Feature | Cabinet Drying | Spray Drying |

|---|---|---|

| Process Type | Heat air circulation in enclosed chamber | Atomization of liquid into hot air stream |

| Drying Speed | Hours | Seconds to minutes |

| Product Form | Slabs or sheets, requires milling to powder | Fine, free-flowing powder |

| Temperature Control | Moderate, risk of uneven heating | Precise, rapid drying minimizes heat damage |

| Energy Efficiency | Lower, longer drying time | Higher, fast drying process |

| Suitable Ingredients | Heat-stable, low-moisture products | Heat-sensitive, liquid or slurry forms |

| Particle Size Control | Limited, requires post-processing | Excellent control via atomizer settings |

| Operational Complexity | Simple, traditional technology | Complex, requires specialized equipment |

| Cost | Lower initial investment | Higher capital and maintenance costs |

Overview of Cabinet Drying and Spray Drying

Cabinet drying involves placing powdered ingredients in trays within a heated chamber, allowing moisture to evaporate gradually at controlled temperatures. This method is suitable for heat-sensitive materials and provides uniform drying with minimal risk of product degradation.

Spray drying transforms liquid or slurry forms of powdered ingredients into fine powders by rapidly drying them with hot air in a spray chamber. It enables precise control over particle size and moisture content, making it ideal for large-scale production. Spray drying offers faster drying times compared to cabinet drying and enhances product solubility and stability.

Key Differences in Drying Processes

| Drying Method | Process Overview | Key Differences |

|---|---|---|

| Cabinet Drying | Utilizes heated air circulated within a closed chamber to slowly remove moisture from powdered ingredients. | Operates at lower temperatures with longer drying times, preserving heat-sensitive nutrients but resulting in reduced throughput. |

| Spray Drying | Atomizes liquid ingredients into a hot air chamber, quickly evaporating moisture to produce fine powders. | Offers rapid drying with high production rates, suitable for thermally stable materials, but may degrade sensitive compounds due to high temperatures. |

Equipment Used in Cabinet vs Spray Drying

Cabinet drying employs heated air circulated within a closed chamber to slowly remove moisture from powdered ingredients, using shelves or trays to hold the product. This equipment is typically simple with a controlled temperature and airflow system suitable for heat-sensitive materials.

Spray drying involves atomizing liquid ingredients into a hot drying chamber, where fine droplets rapidly lose moisture to form powder particles. The equipment consists of an atomizer, a heated air source, and a cyclone separator to collect the powder efficiently and with consistent particle size.

Effects on Powder Quality and Texture

How do cabinet drying and spray drying impact the quality and texture of powdered ingredients? Cabinet drying often results in a coarser texture with uneven moisture distribution, potentially affecting solubility and reconstitution. Spray drying produces finer, more uniform powders with better flowability and enhanced preservation of flavor and bioactive compounds.

Nutritional Retention in Both Methods

Cabinet drying preserves heat-sensitive nutrients effectively by using controlled low temperatures, minimizing nutrient degradation in powdered ingredients. This method maintains higher levels of vitamins such as vitamin C and B-complex compared to high-heat alternatives.

Spray drying exposes ingredients to rapid high temperatures, which can lead to significant nutrient loss, especially in heat-sensitive compounds. However, it offers superior moisture removal and faster drying times, often resulting in longer shelf life despite some nutritional compromise.

Energy Efficiency Comparison

Cabinet drying consumes significantly less energy compared to spray drying due to its lower operating temperatures and simpler equipment design. Spray drying requires rapid evaporation using high temperatures and airflow, resulting in higher electricity consumption. Energy efficiency assessments reveal cabinet drying reduces operational costs for powdered ingredient processing by up to 40% while maintaining acceptable product quality.

Application Suitability for Various Ingredients

Cabinet drying is ideal for heat-sensitive powdered ingredients requiring gentle, uniform drying with minimal thermal degradation. Spray drying suits liquid or slurry forms, enabling rapid moisture removal to produce fine, consistent powders suitable for instant mixing.

- Cabinet drying - Best for delicate herbs and spices that need controlled temperature and airflow to preserve flavor and nutrients.

- Spray drying - Optimal for dairy powders, coffee, and flavorings where fast drying prevents clumping and achieves fine particle size.

- Ingredient consistency - Spray drying produces more uniform particle size compared to cabinet drying, essential for products needing solubility and flowability.

Cost Implications of Each Drying Method

Cabinet drying typically incurs higher energy costs due to longer drying times and larger equipment requirements compared to spray drying. Spray drying offers greater efficiency by rapidly transforming liquids into powders, which reduces operational time and lowers labor expenses. However, initial capital investment for spray drying equipment is significantly higher, impacting upfront cost considerations.

Scalability and Production Volume Differences

Cabinet drying suits small to medium batch sizes with precise temperature control but is limited in scalability for large production volumes. Spray drying supports high-volume continuous production, making it ideal for industrial-scale powdered ingredient manufacturing.

- Cabinet drying scalability - Cabinet drying operates effectively at lower batch volumes but faces challenges when scaling beyond medium production levels due to longer cycle times.

- Spray drying production volume - Spray drying efficiently handles large-scale production with rapid drying rates and continuous processing capabilities.

- Industrial application - Spray drying's scalability makes it the preferred choice for commercial operations requiring consistent quality across massive ingredient batches.

Related Important Terms

Controlled Atmosphere Cabinet Drying

Controlled Atmosphere Cabinet Drying offers precise regulation of humidity, temperature, and oxygen levels, ensuring the retention of volatile compounds and nutrient integrity in powdered ingredients. Compared to Spray Drying, this method minimizes thermal degradation and oxidation, resulting in higher-quality powders with improved flavor and shelf life.

Microencapsulation via Spray Drying

Spray drying is preferred for microencapsulation of powdered ingredients due to its ability to rapidly dehydrate emulsions into stable, uniform microcapsules that protect sensitive bioactives from oxidation and moisture. Cabinet drying, while effective for bulk moisture removal, lacks the precision and protective encapsulation properties crucial for maintaining ingredient functionality in microencapsulated powders.

Hygroscopicity Reduction Technology

Cabinet drying utilizes controlled low temperatures and airflow to reduce moisture content gradually, preserving ingredient integrity but often resulting in higher residual hygroscopicity compared to spray drying. Spray drying rapidly evaporates moisture through atomization and hot air, producing powders with significantly reduced hygroscopicity due to uniform particle size and surface modification, enhancing shelf stability in powdered ingredients.

Low-Temperature Cabinet Dehydration

Low-temperature cabinet dehydration preserves the nutritional integrity and flavor of powdered ingredients by gently removing moisture without exceeding 60degC, reducing thermal degradation compared to spray drying. This method ensures uniform drying and minimizes oxidation, making it ideal for heat-sensitive compounds and maintaining product quality in powdered formulations.

Thermo-sensitive Nutrient Preservation

Cabinet drying preserves thermo-sensitive nutrients by using controlled low temperatures and gentle air circulation, minimizing nutrient degradation during dehydration. Spray drying, while faster, typically involves higher temperatures that can compromise heat-sensitive vitamins and bioactive compounds in powdered ingredients.

Particle Morphology Engineering

Cabinet drying typically produces irregularly shaped particles with lower surface area due to slow moisture removal, whereas spray drying enables precise control over particle morphology, yielding spherical, uniform particles with enhanced flowability and solubility. Spray drying's rapid dehydration promotes engineered particle size distribution critical for improving powder reconstitution and functional performance in powdered ingredients.

Fluidized Bed Post-Treatment

Cabinet drying offers gentle moisture reduction for heat-sensitive powdered ingredients but lacks uniform heat distribution compared to spray drying, which rapidly converts liquids into powders with high surface area. Fluidized bed post-treatment enhances spray-dried powders by improving particle uniformity, moisture content, and flowability, optimizing final product quality for powdered food and pharmaceutical ingredients.

Scale-Up Spray Drying Systems

Scale-up spray drying systems offer precise control over particle size distribution and moisture content, making them ideal for large-scale powdered ingredient production compared to cabinet drying, which is limited by batch size and uneven drying. Spray drying provides higher efficiency, consistent product quality, and better retention of bioactive compounds, essential for industrial food and pharmaceutical applications.

Encapsulated Aroma Stabilization

Cabinet drying preserves encapsulated aroma stability by gently removing moisture at low temperatures, minimizing volatile compound loss and maintaining ingredient integrity. Spray drying rapidly evaporates moisture but may cause greater aroma degradation due to heat exposure, making it less suitable for delicate encapsulated flavors in powdered ingredients.

Cabinet drying vs Spray drying for powdered ingredients. Infographic

cookingdiff.com

cookingdiff.com