Natural drying of meat jerky relies on ambient air circulation and time to remove moisture, preserving flavor but often requiring longer drying periods and exposure to environmental contaminants. Infrared drying uses targeted radiant heat to rapidly eliminate moisture, enhancing efficiency, reducing drying time, and maintaining microbial safety. Infrared methods also help retain the jerky's nutritional value and texture by providing controlled, uniform drying conditions.

Table of Comparison

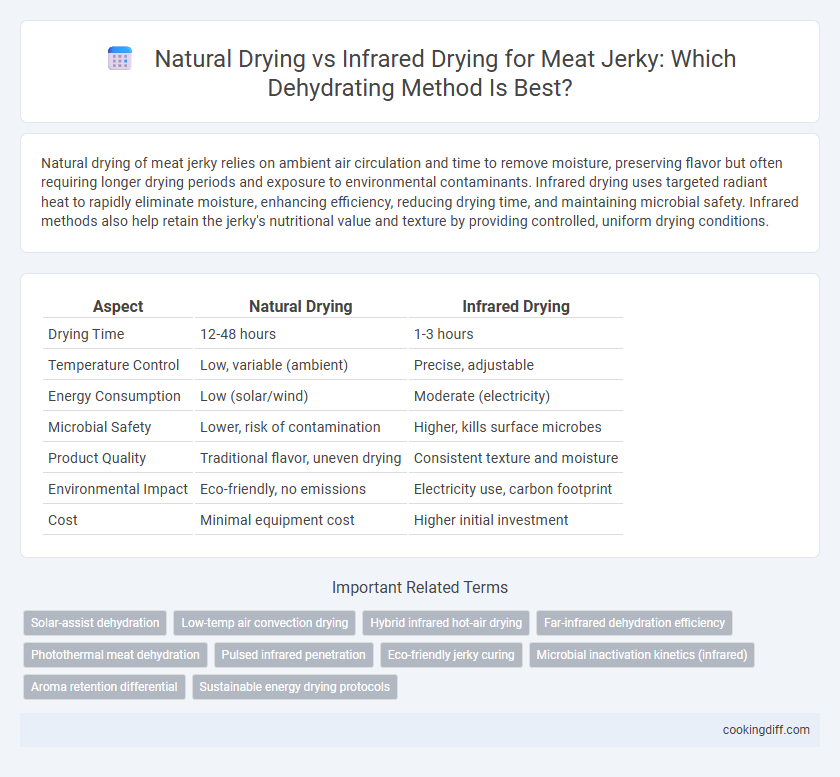

| Aspect | Natural Drying | Infrared Drying |

|---|---|---|

| Drying Time | 12-48 hours | 1-3 hours |

| Temperature Control | Low, variable (ambient) | Precise, adjustable |

| Energy Consumption | Low (solar/wind) | Moderate (electricity) |

| Microbial Safety | Lower, risk of contamination | Higher, kills surface microbes |

| Product Quality | Traditional flavor, uneven drying | Consistent texture and moisture |

| Environmental Impact | Eco-friendly, no emissions | Electricity use, carbon footprint |

| Cost | Minimal equipment cost | Higher initial investment |

Introduction to Meat Jerky Dehydration Methods

Natural drying and infrared drying are two primary methods used to dehydrate meat jerky, each affecting texture and preservation differently. Natural drying relies on ambient air and temperature over time, promoting slow moisture removal while maintaining flavor integrity.

Infrared drying uses electromagnetic radiation to rapidly reduce moisture content, enhancing efficiency and microbial safety. This method can achieve uniform drying and extend shelf life, critical for commercial meat jerky production.

Overview of Natural Drying for Jerky

Natural drying for jerky involves removing moisture from meat using ambient air and sunlight, relying on traditional methods that date back centuries. This process is energy-efficient and retains much of the meat's original flavor and texture, but it requires careful control of temperature and humidity to prevent spoilage.

Natural drying typically takes several days, depending on environmental conditions such as temperature, airflow, and humidity levels. The slower dehydration process allows enzymes to break down muscle fibers, enhancing tenderness and flavor depth. While natural drying is cost-effective, it demands optimal weather and sanitation practices to ensure food safety and high-quality jerky.

Infrared Drying Technology Explained

| Infrared drying technology uses electromagnetic radiation to rapidly heat and evaporate moisture from meat jerky, resulting in a faster dehydration process compared to natural drying. This method ensures uniform drying, preserves nutritional content, and reduces microbial growth by maintaining controlled temperatures. Studies show infrared drying can cut dehydration time by up to 50%, enhancing product safety and shelf life without compromising texture or flavor. |

Drying Efficiency: Natural vs Infrared Methods

Natural drying of meat jerky relies on ambient conditions, often requiring extended hours with variability in temperature and humidity that affects drying efficiency. Infrared drying uses targeted radiation to accelerate moisture removal, significantly reducing processing time and improving consistency across batches.

The efficiency of infrared drying results in less microbial growth risk due to faster dehydration, enhancing food safety compared to slower natural methods. Energy consumption can be optimized with infrared technology, making it a more sustainable option for commercial jerky production over traditional air drying.

Flavor and Texture Differences in Jerky

Natural drying enhances jerky with a rich, smoky flavor and a chewier, more fibrous texture due to slow moisture loss. Infrared drying produces a milder taste with a tender, uniform texture by rapidly removing moisture using heat radiation.

- Flavor intensity - Natural drying imparts deeper, more complex smoky notes, while infrared drying results in subtler flavors.

- Texture profile - Natural drying yields a tougher, more textured jerky, whereas infrared drying creates a softer, more consistent bite.

- Drying duration - Natural drying requires extended time, influencing flavor development, whereas infrared drying is faster, preserving tenderness.

Nutritional Impact: Which Method Preserves More?

Which drying method better preserves the nutritional content of meat jerky? Natural drying retains more essential vitamins and minerals due to its slower, low-temperature process that minimizes nutrient degradation. Infrared drying, while faster, can cause slight losses in heat-sensitive nutrients but enhances microbial safety by rapidly reducing moisture content.

Food Safety Considerations in Jerky Drying

Natural drying relies on ambient air and requires strict control of temperature and humidity to prevent bacterial growth, posing a higher risk of contamination. Infrared drying offers precise temperature regulation, reducing microbial hazards by rapidly lowering moisture content and ensuring consistent food safety standards. Proper validation of drying parameters is essential in both methods to eliminate pathogens like Salmonella and E. coli in meat jerky production.

Energy Consumption and Environmental Impact

Natural drying of meat jerky consumes minimal energy but requires extended drying times, leading to increased vulnerability to contaminants. Infrared drying significantly reduces drying time and energy usage, resulting in a smaller environmental footprint.

- Energy Efficiency - Infrared drying uses targeted heat, lowering electricity consumption compared to natural drying's dependence on ambient conditions.

- Carbon Emissions - Reduced processing time in infrared drying cuts greenhouse gas emissions relative to prolonged natural drying.

- Resource Utilization - Natural drying demands open space and favorable weather, while infrared drying optimizes energy use within controlled environments.

Cost Comparison: Natural vs Infrared Drying

Natural drying of meat jerky involves ambient air and sunlight, resulting in minimal energy costs but longer processing times. Infrared drying uses advanced technology, which increases initial investment and operational expenses but significantly reduces drying duration.

- Energy Costs - Natural drying requires no electricity, making it virtually free, while infrared drying consumes electricity, increasing monthly utility bills.

- Equipment Investment - Natural drying demands little to no specialized equipment, whereas infrared drying entails purchasing and maintaining expensive infrared emitters and control systems.

- Labor and Space - Natural drying needs more space and manual monitoring, leading to higher indirect costs, while infrared drying is more space-efficient and automated, reducing labor expenses.

Overall, infrared drying presents higher upfront and operational costs but offers faster throughput and consistent results compared to natural drying.

Related Important Terms

Solar-assist dehydration

Solar-assisted dehydration enhances natural drying by using infrared radiation to evenly penetrate meat jerky, accelerating moisture evaporation while preserving nutrients and flavor. This hybrid method leverages solar energy to reduce drying time compared to traditional air drying, improving energy efficiency and ensuring consistent jerky texture.

Low-temp air convection drying

Low-temperature air convection drying preserves meat jerky's texture and nutrients by slowly removing moisture through controlled airflow and heat, reducing microbial growth without cooking the product. This method outperforms infrared drying in uniformity and energy efficiency, minimizing surface hardening and ensuring consistent dehydration throughout the jerky.

Hybrid infrared hot-air drying

Hybrid infrared hot-air drying combines the rapid surface heating of infrared radiation with the consistent moisture removal of hot-air drying, enhancing dehydration efficiency and preserving the meat jerky's texture and flavor. This method reduces drying time by up to 40% compared to natural drying, while maintaining microbial safety and nutrient retention better than traditional infrared or natural drying alone.

Far-infrared dehydration efficiency

Far-infrared dehydration significantly enhances moisture removal in meat jerky by penetrating deeper into the meat fibers, accelerating drying rates compared to traditional natural drying methods. This targeted energy absorption reduces drying time and helps preserve texture and flavor while minimizing microbial growth.

Photothermal meat dehydration

Photothermal meat dehydration using infrared drying offers precise temperature control and accelerated moisture removal compared to traditional natural drying methods, reducing microbial growth and enhancing product safety. Infrared drying ensures uniform heat distribution, preserving the jerky's texture and nutritional quality by minimizing oxidation and enzymatic degradation.

Pulsed infrared penetration

Pulsed infrared drying enhances meat jerky dehydration by penetrating deeper into the tissue compared to natural drying, resulting in more uniform moisture removal and reduced drying times. This method improves texture retention and microbial safety by targeting internal water content without over-drying the surface.

Eco-friendly jerky curing

Natural drying preserves meat jerky through ambient air exposure, minimizing energy consumption and reducing carbon footprint, making it an environmentally sustainable curing method. Infrared drying accelerates moisture removal with targeted heat emission, offering energy efficiency and decreased drying time while maintaining eco-friendly production standards.

Microbial inactivation kinetics (infrared)

Infrared drying accelerates microbial inactivation kinetics in meat jerky by delivering uniform heat penetration, resulting in faster and more effective reduction of pathogens compared to natural drying methods. This enhanced microbial control minimizes spoilage risk and extends shelf life while preserving the jerky's nutritional and sensory properties.

Aroma retention differential

Natural drying preserves the inherent aroma compounds in meat jerky by allowing slow moisture evaporation, which maintains the complex flavor profile. Infrared drying accelerates dehydration but can cause volatile aroma compounds to dissipate rapidly, leading to a diminished sensory experience.

Natural drying vs Infrared drying for meat jerky. Infographic

cookingdiff.com

cookingdiff.com