Vacuum drying jars preserve nutrients and flavor in pet food by removing moisture at lower temperatures compared to classic dehydrators, which use prolonged heat exposure that can degrade sensitive vitamins. The vacuum environment reduces oxidation and drying time, resulting in a more nutritious, palatable treat. Classic dehydrators offer consistent drying but lack the gentle preservation benefits of vacuum drying technology.

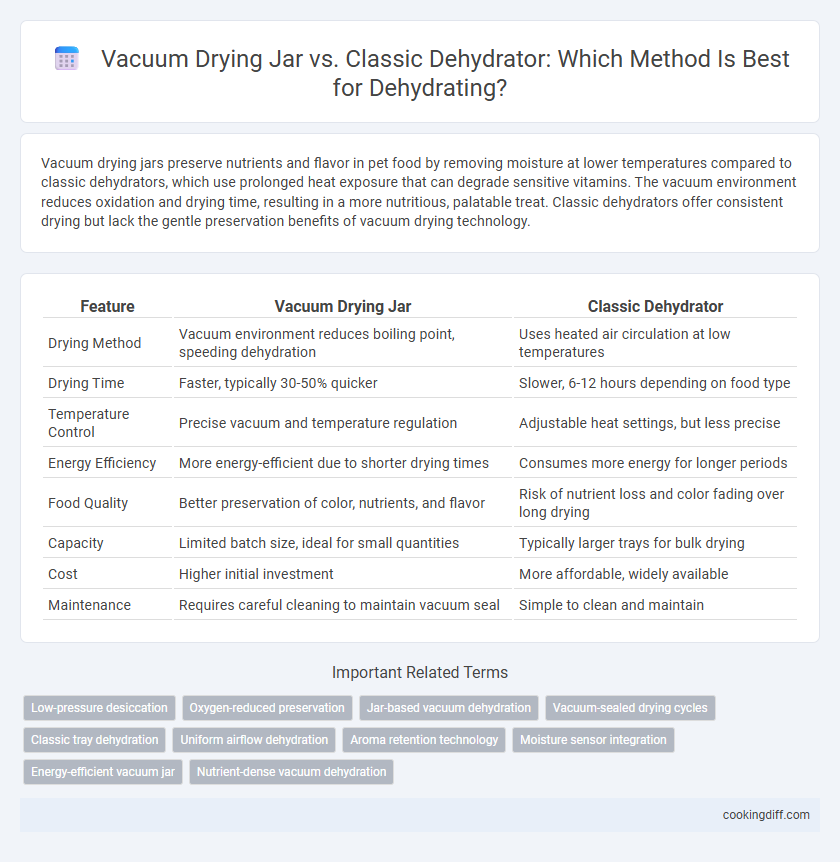

Table of Comparison

| Feature | Vacuum Drying Jar | Classic Dehydrator |

|---|---|---|

| Drying Method | Vacuum environment reduces boiling point, speeding dehydration | Uses heated air circulation at low temperatures |

| Drying Time | Faster, typically 30-50% quicker | Slower, 6-12 hours depending on food type |

| Temperature Control | Precise vacuum and temperature regulation | Adjustable heat settings, but less precise |

| Energy Efficiency | More energy-efficient due to shorter drying times | Consumes more energy for longer periods |

| Food Quality | Better preservation of color, nutrients, and flavor | Risk of nutrient loss and color fading over long drying |

| Capacity | Limited batch size, ideal for small quantities | Typically larger trays for bulk drying |

| Cost | Higher initial investment | More affordable, widely available |

| Maintenance | Requires careful cleaning to maintain vacuum seal | Simple to clean and maintain |

Introduction to Dehydrating: Vacuum Drying Jars vs Classic Dehydrators

Vacuum drying jars use reduced air pressure to lower the boiling point of water, enabling faster and more efficient dehydration at lower temperatures. Classic dehydrators rely on heated air circulation to remove moisture over a longer period, preserving texture and nutrients.

- Vacuum Drying Efficiency - Vacuum drying jars speed up dehydration by vacuum-sealing and reducing oxidation risk, ideal for delicate foods.

- Temperature Control - Classic dehydrators offer adjustable heat settings that accommodate a wide range of food types and drying needs.

- Moisture Removal Method - Vacuum jars extract moisture through pressure difference, while classic dehydrators use consistent airflow to evaporate water content.

How Vacuum Drying Jars Work for Food Dehydration

Vacuum drying jars remove moisture from food by creating a low-pressure environment, which lowers the boiling point of water for faster dehydration at lower temperatures. This process preserves nutrients and flavors more effectively than classic dehydrators, which rely on heated air circulation.

- Low-pressure environment - Vacuum drying jars use a vacuum pump to reduce air pressure inside the jar, accelerating moisture evaporation.

- Lower temperature dehydration - The reduced boiling point allows food to dry without exposing it to high heat, protecting delicate nutrients.

- Flavor and nutrient retention - Vacuum drying minimizes oxidation and degradation, resulting in higher quality dehydrated food compared to classic dehydrators.

The Classic Dehydrator: Operation and Process

The Classic Dehydrator operates by circulating warm air through multiple trays, effectively removing moisture from food over several hours. This method relies on a consistent temperature range, typically between 95degF and 160degF, to preserve nutrients while achieving optimal dehydration. Unlike vacuum drying jars, classic dehydrators are designed for larger batches, offering a straightforward and efficient drying process for fruits, vegetables, and meats.

Efficiency: Comparing Drying Speeds and Results

Which method offers faster drying speeds and better results: vacuum drying jar or classic dehydrator? Vacuum drying jars significantly reduce drying time by lowering the boiling point of water, enabling efficient moisture removal at lower temperatures. Classic dehydrators, while slower, provide consistent airflow and uniform drying, making them suitable for larger batches but less time-efficient overall.

Nutrient Retention: Which Method Preserves More?

Vacuum drying jars preserve more nutrients by drying foods at lower temperatures and reduced oxygen levels, minimizing oxidation and degradation of heat-sensitive vitamins. Classic dehydrators use higher temperatures and exposure to air, which can lead to greater nutrient loss, especially of vitamin C and some B vitamins. Studies show vacuum drying can retain up to 60% more antioxidants compared to traditional dehydrating methods.

Energy Consumption and Environmental Impact

| Vacuum Drying Jar | Consumes up to 30% less energy compared to classic dehydrators due to reduced drying temperatures and faster moisture removal. Lower energy usage leads to a decreased carbon footprint, making it a more environmentally friendly option for dehydration. Utilizes a sealed environment which minimizes heat loss and reduces overall electricity consumption. |

| Classic Dehydrator | Typically operates at higher temperatures for longer periods, resulting in increased energy consumption and higher operational costs. The extended drying cycles contribute to greater CO2 emissions and a larger environmental impact. Lack of insulation increases heat loss, reducing energy efficiency during dehydration. |

Capacity and Batch Size: What Suits Your Needs?

Vacuum drying jars typically offer smaller capacity suitable for small-batch dehydration, preserving flavor and nutrients more effectively. Classic dehydrators provide larger batch sizes, ideal for processing bulk fruits, vegetables, and herbs efficiently.

Choosing between a vacuum drying jar and a classic dehydrator depends on your typical batch size and available space. Vacuum jars excel in precise, nutrient-retentive drying, while classic dehydrators accommodate higher volume needs and diverse food types.

Cost Comparison: Initial Investment and Maintenance

Vacuum drying jars generally require a higher initial investment compared to classic dehydrators due to their advanced technology and materials. Classic dehydrators are more affordable upfront, making them accessible for casual users.

Maintenance costs for vacuum drying jars tend to be higher because of the need for specialized parts and occasional calibration to maintain vacuum pressure. Classic dehydrators have simpler components that are easier and cheaper to clean and replace. Over time, the lower upkeep expenses of classic dehydrators often offset their initial cost advantage for many users.

Ease of Use and Cleaning: User Experience

Vacuum drying jars offer a compact design that simplifies setup and operation compared to classic dehydrators, which often require more time to arrange trays and adjust settings. Cleaning a vacuum drying jar is generally faster due to fewer components and smooth surfaces, while classic dehydrators may have multiple trays that are more cumbersome to clean thoroughly.

- Compact design - Vacuum drying jars streamline the drying process with minimal parts for easier handling.

- Quick cleaning - Smooth surfaces inside the jar reduce cleaning time compared to multi-tray dehydrators.

- User-friendly controls - Vacuum drying jars often feature simple, intuitive controls for hassle-free operation.

Users looking for convenience and ease in both use and maintenance often prefer vacuum drying jars over classic dehydrators.

Related Important Terms

Low-pressure desiccation

Vacuum drying jars utilize low-pressure desiccation to rapidly remove moisture at lower temperatures, preserving nutrient content and preventing oxidation better than classic dehydrators. Classic dehydrators rely on hot air circulation at atmospheric pressure, which can lead to longer drying times and potential heat damage to sensitive foods.

Oxygen-reduced preservation

Vacuum drying jars create an oxygen-reduced environment that significantly slows oxidation and microbial growth, preserving food color, flavor, and nutrients more effectively than classic dehydrators. Classic dehydrators rely on circulating warm, dry air, which exposes food to oxygen and can lead to faster degradation despite efficient moisture removal.

Jar-based vacuum dehydration

Jar-based vacuum dehydration uses a sealed environment to remove moisture from food at lower temperatures, preserving nutrients and flavors better than classic dehydrators. This method also reduces oxidation and extends shelf life, making it ideal for delicate items like herbs and fruits.

Vacuum-sealed drying cycles

Vacuum drying jars utilize vacuum-sealed drying cycles to remove moisture at lower temperatures, preserving nutrients and flavor more effectively than classic dehydrators, which rely on continuous airflow and heat. This method significantly reduces oxidation and drying time, making vacuum drying jars a superior choice for high-quality food preservation.

Classic tray dehydration

Classic tray dehydration in traditional dehydrators offers even airflow distribution and consistent temperature control, ensuring uniform moisture removal across all food trays. This method is especially efficient for drying fruits, herbs, and vegetables due to its simple design, lower cost, and reliable performance compared to vacuum drying jars.

Uniform airflow dehydration

Vacuum drying jars provide a controlled low-pressure environment that enhances moisture removal through uniform airflow, reducing oxidation and preserving nutrient quality more effectively than classic dehydrators. Classic dehydrators rely on heated air circulation, which can result in uneven airflow and inconsistent dehydration, potentially compromising texture and flavor.

Aroma retention technology

Vacuum drying jars preserve aroma by reducing oxygen exposure and lowering drying temperatures, which minimizes volatile compound loss during dehydration. Classic dehydrators rely on heated air circulation, often causing more significant aroma degradation due to prolonged exposure to heat and oxygen.

Moisture sensor integration

Vacuum drying jars with integrated moisture sensors offer precise control over humidity levels, optimizing dehydration by preventing over-drying and preserving food quality more effectively than classic dehydrators. This sensor integration enables real-time monitoring and automatic adjustment, enhancing energy efficiency and ensuring consistent moisture removal for superior drying results.

Energy-efficient vacuum jar

Vacuum drying jars provide superior energy efficiency compared to classic dehydrators by reducing drying time through lower pressure environments that accelerate moisture removal. This method not only preserves nutritional quality but also consumes significantly less electricity, making it ideal for sustainable food preservation.

Vacuum drying jar vs Classic dehydrator for dehydrating. Infographic

cookingdiff.com

cookingdiff.com