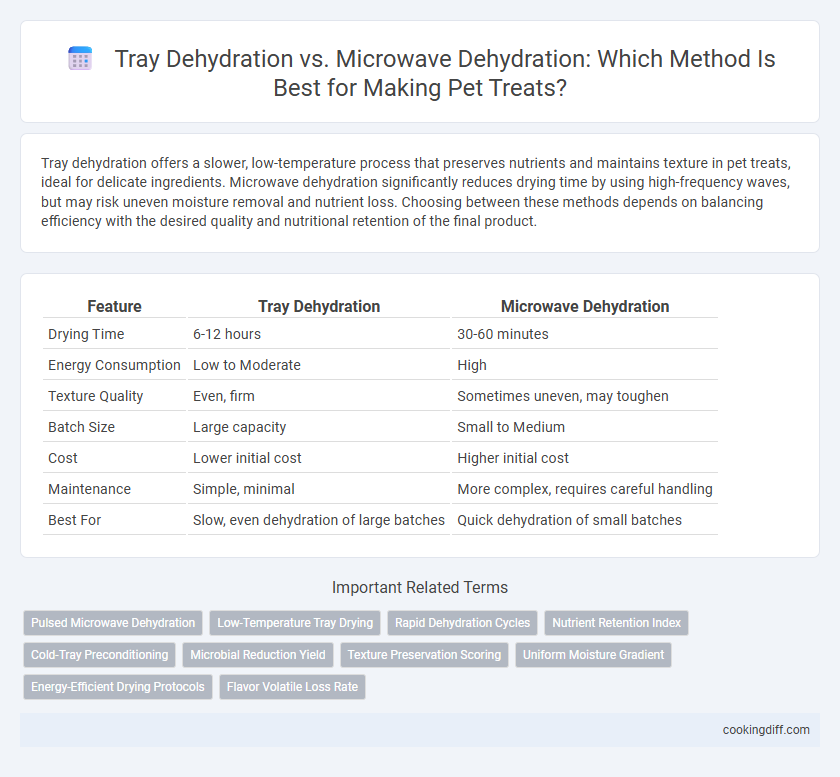

Tray dehydration offers a slower, low-temperature process that preserves nutrients and maintains texture in pet treats, ideal for delicate ingredients. Microwave dehydration significantly reduces drying time by using high-frequency waves, but may risk uneven moisture removal and nutrient loss. Choosing between these methods depends on balancing efficiency with the desired quality and nutritional retention of the final product.

Table of Comparison

| Feature | Tray Dehydration | Microwave Dehydration |

|---|---|---|

| Drying Time | 6-12 hours | 30-60 minutes |

| Energy Consumption | Low to Moderate | High |

| Texture Quality | Even, firm | Sometimes uneven, may toughen |

| Batch Size | Large capacity | Small to Medium |

| Cost | Lower initial cost | Higher initial cost |

| Maintenance | Simple, minimal | More complex, requires careful handling |

| Best For | Slow, even dehydration of large batches | Quick dehydration of small batches |

Introduction to Dehydrating Pet Treats

Tray dehydration and microwave dehydration are popular methods for preserving pet treats by removing moisture to extend shelf life and maintain nutritional content. Tray dehydration uses low heat and prolonged drying times, making it ideal for retaining texture and flavor in natural pet treats.

Microwave dehydration offers a faster drying process by using electromagnetic waves to heat moisture internally, which can be efficient for bulk production but may risk uneven drying. Choosing the right dehydration technique depends on the specific type of pet treat and desired quality outcomes.

Overview of Tray Dehydration

Tray dehydration utilizes low heat and air circulation to slowly remove moisture from pet treats, preserving texture and nutrients. This method is energy-efficient and ideal for small to medium-scale production of dehydrated pet snacks.

- Even drying - Hot air evenly circulates across trays ensuring uniform moisture removal.

- Gentle temperature control - Allows low heat settings to maintain nutrient integrity in pet treats.

- Simple operation - Typically requires minimal supervision and straightforward setup for consistent results.

Overview of Microwave Dehydration

Microwave dehydration uses high-frequency electromagnetic waves to rapidly remove moisture from pet treats, preserving nutritional value and flavor more effectively than traditional methods. This technique significantly reduces drying time compared to tray dehydration, enhancing production efficiency and throughput. Microwave dehydration also promotes uniform drying, minimizing the risk of microbial growth and spoilage during storage.

Nutritional Retention: Tray vs Microwave

Tray dehydration for pet treats preserves nutrients by slowly removing moisture at low temperatures, minimizing nutrient degradation. Microwave dehydration uses high heat rapidly, which can cause some loss of sensitive vitamins and enzymes.

Microwave dehydration offers faster processing time but risks reducing overall nutritional retention compared to tray dehydration. Tray dehydration maintains higher levels of essential nutrients such as vitamins A, C, and B-complex due to its gentle drying method. Pet treat manufacturers often prefer tray dehydration to ensure optimal nutritional value and palatability.

Texture and Palatability Comparison

Tray dehydration preserves the natural texture of pet treats by slowly removing moisture, resulting in chewier and more fibrous products that pets often find satisfying. Microwave dehydration offers faster drying times but can create uneven textures and sometimes tougher edges due to rapid moisture loss. Palatability tends to be higher in tray-dehydrated treats because the gentle process maintains flavor compounds better than microwave methods.

Time Efficiency: Which is Faster?

| Dehydration Method | Time Efficiency | Average Time Required |

|---|---|---|

| Tray Dehydration | Slower process due to gradual heat distribution | 8-12 hours per batch |

| Microwave Dehydration | Faster drying through rapid heat generation | 30 minutes to 1 hour per batch |

Energy Consumption and Cost Analysis

Which dehydration method consumes less energy and reduces overall costs for pet treat production? Tray dehydration typically uses more energy due to longer drying times, increasing operational costs significantly. Microwave dehydration offers faster processing with lower energy consumption, making it a cost-effective alternative for large-scale pet treat manufacturing.

Safety and Contamination Risks

Tray dehydration provides a slower, more controlled drying process, reducing the risk of overheating and uneven moisture removal that can compromise pet treat safety. Microwave dehydration offers rapid drying but can create hotspots, increasing the potential for contamination if not carefully monitored.

- Even Drying in Tray Dehydration - Ensures consistent moisture levels throughout treats, minimizing bacterial growth risks.

- Hotspot Formation in Microwave Dehydration - Causes uneven drying, which may leave areas prone to microbial contamination.

- Temperature Control - Tray methods allow precise temperature regulation critical for pathogen reduction compared to microwave techniques.

Suitability for Different Pet Treat Types

Tray dehydration offers gentle, consistent heat ideal for moisture-rich treats like fruits and vegetables, preserving natural flavors and nutrients. Its controlled environment suits delicate pet snacks that require slow drying to maintain texture and safety.

Microwave dehydration provides rapid moisture removal, making it suitable for denser, protein-based treats such as jerky and meat strips. The fast process helps retain chewy texture but may not be optimal for very delicate ingredients sensitive to intense heat.

Related Important Terms

Pulsed Microwave Dehydration

Pulsed microwave dehydration offers rapid, energy-efficient moisture removal while preserving nutritional value and texture in pet treats, outperforming traditional tray dehydration by reducing processing time and minimizing heat damage. This method uses intermittent microwave bursts to evenly dehydrate products, enhancing shelf life and maintaining palatability without compromising essential nutrients.

Low-Temperature Tray Drying

Low-temperature tray drying preserves the nutritional value and natural enzymes in pet treats by gently removing moisture over extended periods, making it ideal for sensitive ingredients. Unlike microwave dehydration, which uses rapid, high heat that can degrade nutrients, tray dehydration ensures even drying and maintains the product's texture and flavor integrity.

Rapid Dehydration Cycles

Tray dehydration offers consistent low-temperature drying ideal for preserving nutrients but requires longer cycles, while microwave dehydration achieves rapid dehydration cycles through volumetric heating, significantly reducing processing time and retaining moisture uniformity in pet treats. Pet treat manufacturers benefit from microwave dehydration's speed and efficiency, enhancing production throughput compared to traditional tray methods.

Nutrient Retention Index

Tray dehydration preserves the Nutrient Retention Index more effectively by using low, consistent heat that minimizes nutrient degradation in pet treats. Microwave dehydration, although faster, can cause uneven heating that reduces the Nutrient Retention Index and compromises essential vitamins and enzymes.

Cold-Tray Preconditioning

Cold-tray preconditioning in tray dehydration preserves nutrient integrity by maintaining low temperatures during moisture removal, resulting in pet treats with enhanced texture and flavor retention. Microwave dehydration accelerates the drying process but risks heat-induced nutrient loss, making cold-tray methods preferable for producing high-quality, minimally processed treats.

Microbial Reduction Yield

Tray dehydration typically achieves moderate microbial reduction by slowly removing moisture at lower temperatures, preserving nutrient content but requiring longer processing times, whereas microwave dehydration offers rapid moisture removal with higher temperatures that result in superior microbial reduction yield, significantly enhancing pet treat safety by effectively eliminating pathogens. Studies indicate microwave dehydration can reduce microbial load by up to 99.9%, compared to approximately 90-95% reduction with traditional tray dehydration methods.

Texture Preservation Scoring

Tray dehydration for pet treats scores higher in texture preservation, maintaining the chewy and fibrous qualities preferred by pets due to its slower, even drying process. Microwave dehydration, while faster, often results in uneven moisture removal leading to a tougher, less consistent texture and lower texture preservation scoring.

Uniform Moisture Gradient

Tray dehydration provides a slower, more uniform moisture gradient throughout pet treats by evenly circulating warm air, reducing the risk of uneven drying or surface hardening. Microwave dehydration delivers rapid moisture removal but often creates inconsistent moisture gradients, leading to patchy textures and potential hotspots in treats.

Energy-Efficient Drying Protocols

Tray dehydration uses low, consistent heat over several hours, resulting in moderate energy consumption, while microwave dehydration rapidly removes moisture through high-frequency waves, significantly reducing drying time and overall energy use. Microwave dehydration offers an energy-efficient drying protocol by minimizing heat exposure and preserving nutrient quality in pet treats.

Tray dehydration vs Microwave dehydration for pet treats. Infographic

cookingdiff.com

cookingdiff.com