Jerky makers provide consistent heat and airflow, making them ideal for producing traditional, evenly dried jerky with a firm texture. Biltong boxes use natural air circulation and vinegar curing, resulting in a softer, more tender dried meat with a distinct tangy flavor. Choosing between a jerky maker and a biltong box depends on the desired texture, flavor profile, and drying technique for your meat.

Table of Comparison

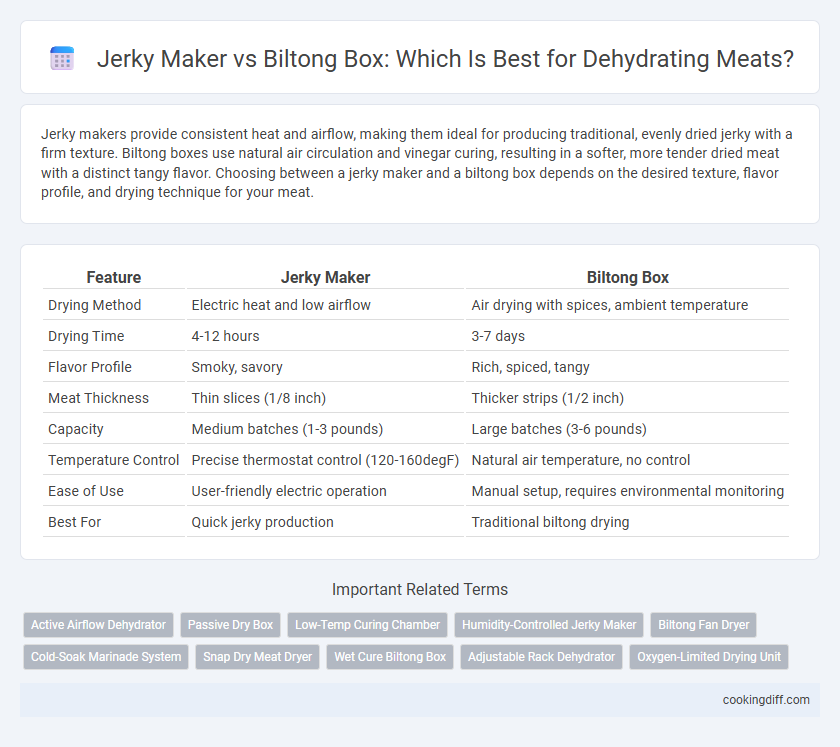

| Feature | Jerky Maker | Biltong Box |

|---|---|---|

| Drying Method | Electric heat and low airflow | Air drying with spices, ambient temperature |

| Drying Time | 4-12 hours | 3-7 days |

| Flavor Profile | Smoky, savory | Rich, spiced, tangy |

| Meat Thickness | Thin slices (1/8 inch) | Thicker strips (1/2 inch) |

| Capacity | Medium batches (1-3 pounds) | Large batches (3-6 pounds) |

| Temperature Control | Precise thermostat control (120-160degF) | Natural air temperature, no control |

| Ease of Use | User-friendly electric operation | Manual setup, requires environmental monitoring |

| Best For | Quick jerky production | Traditional biltong drying |

Introduction: Jerky Maker vs Biltong Box for Meat Dehydration

Jerky makers and biltong boxes are specialized tools designed for dehydrating meats, each suited to different drying methods and flavor profiles. Understanding their unique features helps optimize the meat drying process for desired textures and tastes.

- Jerky Maker - Uses controlled heat and airflow to dry thinly sliced meat quickly and evenly.

- Biltong Box - Employs air circulation with lower temperatures and higher humidity ideal for curing thicker meat strips.

- Meat Preparation - Jerky requires marinated, lean slices while biltong favors spiced, thicker cuts for its traditional flavor.

Choosing between a jerky maker and a biltong box depends on the preferred drying technique and final meat consistency.

Key Differences Between Jerky Makers and Biltong Boxes

Jerky makers use low heat and circulating air to rapidly dry thin strips of meat into a chewy, shelf-stable snack, while biltong boxes rely on natural air drying with minimal heat, preserving a tender, flavorful texture. Jerky makers often incorporate controlled temperature settings and fans, whereas biltong boxes use ambient airflow and drying racks.

Biltong boxes produce meat with a higher moisture content and a more pronounced vinegar and spice flavor, reflecting traditional South African methods. Jerky makers focus on quicker dehydration and uniform drying, resulting in a drier, more shelf-stable product. Choosing between these depends on desired texture, drying time, and flavor preferences in meat preservation.

Meat Preparation Techniques for Jerky and Biltong

Jerky makers require thinly sliced meat, typically marinated in a salty, spicy solution to enhance flavor and ensure even dehydration. Precise slicing and uniform thickness are critical for consistent drying and preventing bacterial growth during the jerky-making process.

Biltong boxes accommodate thicker cuts of meat that are cured with vinegar, salt, and spices, allowing the meat to air dry slowly for several days. The preparation involves minimal slicing, focusing instead on curing techniques that promote tender texture and rich, tangy flavor development in biltong.

Temperature and Drying Control: Which Device Excels?

Which device offers superior temperature and drying control for dehydrating meats, a jerky maker or a biltong box? Jerky makers provide precise temperature regulation ranging from 130degF to 160degF, ensuring consistent drying ideal for thin, sliced meats. In contrast, biltong boxes rely on ambient conditions and adjustable airflow, offering less precise temperature control but allowing for slower, air-dried meat preservation favored in traditional biltong preparation.

Flavor Profiles: Jerky vs Biltong Results

Jerky makers typically produce meat with a smoky, sweet, and spicy flavor due to the low heat and smoke infusion during dehydration. Biltong boxes, on the other hand, create a tangy, savory, and slightly fermented taste by using air drying with vinegar and spices. The choice between a jerky maker and biltong box significantly impacts the intensity and complexity of the meat's flavor profile.

Equipment Size and Batch Capacity Comparison

Jerky makers typically have a compact design with smaller trays, making them ideal for limited kitchen space but restricting batch capacity to around 4-6 pounds of meat per cycle. Biltong boxes are generally larger, using vertical hanging systems that accommodate bigger cuts and batch sizes up to 8-10 pounds.

The space-saving nature of jerky makers suits casual users seeking quick, small batches, whereas biltong boxes cater to enthusiasts or commercial producers who require higher volume output and continuous airflow. The difference in size directly impacts drying time and uniformity, with biltong boxes often providing more consistent dehydration for larger meat portions.

Ease of Use and Maintenance

Jerky makers offer straightforward controls and preset temperature settings, making them easy to operate for beginners. Biltong boxes require more manual attention, such as monitoring airflow and adjusting drying times, which can complicate the process. In terms of maintenance, jerky makers typically have removable trays and non-stick surfaces that simplify cleaning compared to the wooden or mesh components of biltong boxes that may absorb moisture and odors.

Cost Efficiency: Initial and Long-Term Investment

| Jerky Maker | Biltong Box |

|---|---|

| Typically requires an initial investment between $50 and $150, with electric models offering consistent drying temperatures for faster processing times. | Costs range from $30 to $100 for basic models, using less electricity and relying on air flow and salt curing, which may extend drying times. |

| Long-term costs include electricity consumption averaging 100-250 watts per hour, increasing utility bills depending on frequency of use. | Lower electricity usage due to passive drying methods results in reduced ongoing energy expenses, making it more cost-effective over extended periods. |

| Replacement parts and maintenance costs can elevate total expenses but generally remain affordable due to modular design. | Minimal maintenance and durable materials often result in fewer additional costs, sustaining its low long-term financial impact. |

Suitable Meats for Jerky Makers and Biltong Boxes

Jerky makers are best suited for lean meats like beef, turkey, and venison, which require even drying to prevent spoilage. Biltong boxes accommodate thicker cuts and fattier meats, as their curing process includes vinegar and spices that aid in preservation and flavor development.

- Lean Meats in Jerky Makers - Ideal for thinly sliced, low-fat meats to ensure quick and uniform dehydration.

- Thicker Cuts in Biltong Boxes - Suitable for chunkier meat pieces that benefit from air-drying and marinade absorption.

- Fat Content Consideration - Jerky makers require low-fat meats to avoid rancidity, while biltong boxes tolerate higher fat due to curing agents.

Related Important Terms

Active Airflow Dehydrator

Active airflow dehydrators in jerky makers ensure even moisture removal by circulating warm air consistently, preventing spoilage and preserving meat texture more effectively than traditional biltong boxes. Jerky makers with adjustable temperature controls and fans optimize dehydration by facilitating rapid drying, while biltong boxes rely on passive airflow, resulting in longer drying times and less uniform results.

Passive Dry Box

A Passive Dry Box uses natural airflow and humidity control to dehydrate meats slowly, preserving flavor and texture without electricity. Compared to electric Jerky Makers, Passive Dry Boxes like Biltong Boxes offer a traditional method suited for curing biltong, emphasizing low temperature and moisture balance.

Low-Temp Curing Chamber

A jerky maker provides consistent low-temperature heat circulation ideal for uniform drying, while a biltong box relies on ambient airflow with lower temperature control suited for curing rather than dehydrating meats. Low-temp curing chambers in biltong boxes maintain optimal humidity and air exchange, preserving flavor and tenderness without over-drying.

Humidity-Controlled Jerky Maker

Humidity-controlled jerky makers maintain precise moisture levels to ensure evenly dehydrated meats with a chewy texture, making them ideal for consistent jerky production. In contrast, biltong boxes rely on airflow and natural drying, which may result in variable humidity and longer drying times, affecting flavor and texture consistency.

Biltong Fan Dryer

The Biltong Fan Dryer offers consistent airflow and controlled humidity, ensuring even dehydration and superior texture compared to traditional jerky makers. Its specialized design accelerates drying time while preserving the natural flavors and nutritional value of meats in the biltong preparation process.

Cold-Soak Marinade System

Jerky makers typically use heat for dehydration, which can diminish the flavor impact of a cold-soak marinade by accelerating moisture loss and cooking the meat unevenly. Biltong boxes maintain low temperatures and consistent airflow, enhancing the marinade's penetration through the cold-soak system and preserving the meat's tender texture and rich flavor.

Snap Dry Meat Dryer

The Snap Dry Meat Dryer offers superior moisture control and consistent airflow compared to traditional jerky makers and biltong boxes, ensuring evenly dehydrated meat with optimal texture. Its advanced temperature regulation and airtight sealing distinguish it as the ideal choice for preserving meat quality and extending shelf life.

Wet Cure Biltong Box

Wet Cure Biltong Boxes use a controlled moist environment to enhance flavor penetration and tenderness during dehydration, preserving the natural juices of the meat unlike traditional Jerky Makers which rely on dry heat and airflow to rapidly remove moisture. The wet cure method in Biltong Boxes results in a distinct texture and richer taste profile, making it ideal for meats requiring longer marination and delicate drying conditions.

Adjustable Rack Dehydrator

An adjustable rack dehydrator offers customizable layering for optimal air circulation, making it ideal for both jerky makers and biltong boxes when drying various cuts of meat. This flexibility enhances even moisture removal, preserving meat texture and flavor efficiently throughout the dehydration process.

Jerky maker vs Biltong box for meats Infographic

cookingdiff.com

cookingdiff.com