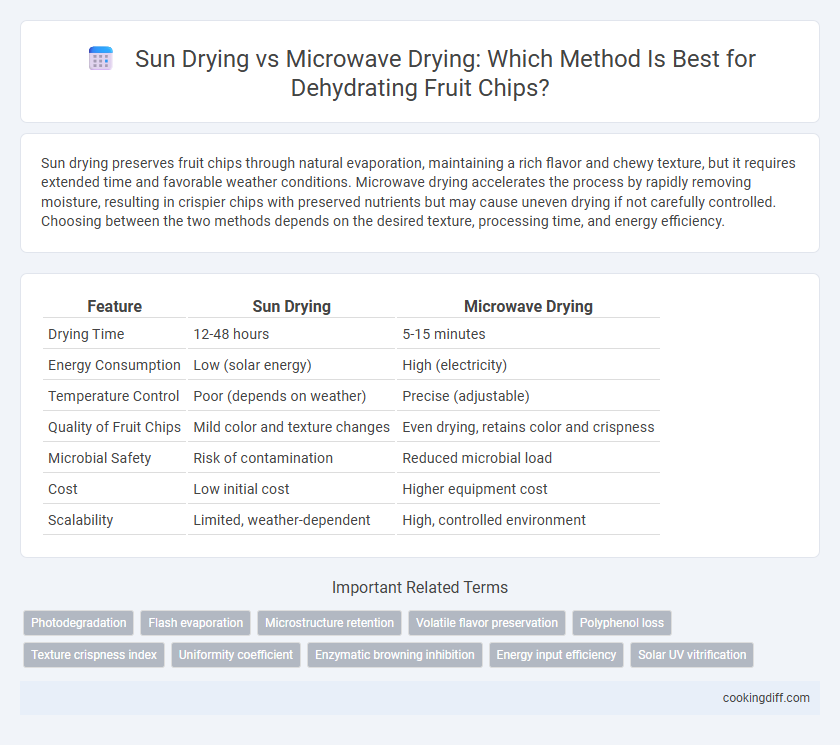

Sun drying preserves fruit chips through natural evaporation, maintaining a rich flavor and chewy texture, but it requires extended time and favorable weather conditions. Microwave drying accelerates the process by rapidly removing moisture, resulting in crispier chips with preserved nutrients but may cause uneven drying if not carefully controlled. Choosing between the two methods depends on the desired texture, processing time, and energy efficiency.

Table of Comparison

| Feature | Sun Drying | Microwave Drying |

|---|---|---|

| Drying Time | 12-48 hours | 5-15 minutes |

| Energy Consumption | Low (solar energy) | High (electricity) |

| Temperature Control | Poor (depends on weather) | Precise (adjustable) |

| Quality of Fruit Chips | Mild color and texture changes | Even drying, retains color and crispness |

| Microbial Safety | Risk of contamination | Reduced microbial load |

| Cost | Low initial cost | Higher equipment cost |

| Scalability | Limited, weather-dependent | High, controlled environment |

Introduction to Fruit Chip Dehydration Methods

Sun drying and microwave drying are two prevalent methods used in fruit chip dehydration, each with distinct advantages. Sun drying relies on natural solar energy, which is cost-effective but susceptible to environmental conditions, affecting drying time and product quality. Microwave drying offers rapid moisture removal through electromagnetic waves, enhancing texture and color retention while reducing processing duration.

How Sun Drying Works for Fruit Chips

Sun drying for fruit chips uses natural solar heat to remove moisture, preserving nutrients while creating a chewy texture. This traditional method requires several days under direct sunlight and airflow for effective dehydration.

- Natural Solar Heat - Sun drying exposes fruit slices to sunlight, which slowly evaporates moisture content without the need for electrical energy.

- Extended Drying Time - The process typically takes 2 to 5 days depending on weather conditions, ensuring gradual dehydration for optimal texture.

- Energy Efficiency - Utilizing ambient heat makes sun drying a cost-effective and eco-friendly method for producing fruit chips.

Microwave Drying: An Overview

Microwave drying accelerates the moisture removal process in fruit chips by using electromagnetic waves that penetrate the product, leading to rapid internal heating. This method preserves more nutrients and enhances color retention compared to traditional sun drying.

Microwave drying offers precise control over temperature and drying time, reducing the risk of microbial growth and spoilage during dehydration. It also significantly shortens the overall drying cycle, improving production efficiency for industrial-scale fruit chip manufacturing.

Equipment and Preparation Needed

Sun drying fruit chips requires minimal equipment, primarily relying on natural sunlight and mesh drying trays to protect the fruit from insects. Microwave drying necessitates specialized microwave ovens designed for dehydration, offering faster and more controlled drying.

- Sun drying equipment - Mesh trays and a sunny, well-ventilated outdoor space are essential for effective sun drying.

- Microwave drying equipment - Requires a microwave dehydrator or a microwave with adjustable power settings and drying racks.

- Preparation needed - Both methods require uniform fruit slicing and pre-treatment such as blanching or soaking in lemon juice to prevent oxidation and preserve color.

Time Requirements: Sun Drying vs Microwave Drying

How do time requirements differ between sun drying and microwave drying for fruit chips? Sun drying typically takes several days to properly dehydrate fruit chips due to slower moisture evaporation under natural conditions. Microwave drying significantly reduces dehydration time to minutes by using electromagnetic waves to rapidly heat and remove moisture from the fruit chips.

Impact on Nutrient Retention

Sun drying fruit chips preserves vitamins such as vitamin C and antioxidants moderately due to the slow dehydration process and exposure to natural sunlight, but prolonged drying time can lead to nutrient degradation. Microwave drying offers rapid moisture removal, significantly reducing nutrient loss by minimizing heat exposure and preserving essential nutrients like vitamin C and phenolic compounds.

Sun drying maintains more fiber content in fruit chips because of lower processing temperatures, although it may result in microbial contamination if not properly monitored. Microwave drying provides a more controlled environment that enhances nutrient retention and microbiological safety, making it a preferred method for producing nutrient-rich fruit chips.

Differences in Taste and Texture

Sun drying preserves the natural sweetness of fruit chips by slowly evaporating moisture, resulting in a chewier texture with a slightly caramelized flavor. Microwave drying rapidly removes water content, producing a crispier texture but often leading to a less intense, sometimes slightly cooked taste. The choice between these methods significantly impacts the final fruit chip's mouthfeel and flavor profile, with sun drying favoring richness and microwave drying enhancing crunchiness.

Energy Efficiency and Environmental Impact

Sun drying fruit chips utilizes solar energy, resulting in minimal electricity consumption and a significantly lower carbon footprint compared to microwave drying. This method reduces dependence on non-renewable energy sources, making it an eco-friendly option for dehydrating fruits.

Microwave drying offers faster dehydration times but consumes more electricity, leading to higher energy costs and increased greenhouse gas emissions. The environmental impact of microwave drying is substantial due to its reliance on electrical power, often sourced from fossil fuels. Choosing sun drying supports sustainable practices by leveraging natural energy and minimizing environmental harm.

Food Safety Considerations

| Sun drying | Relies on natural heat and airflow, increasing exposure to contaminants like dust, insects, and bacteria, raising the risk of microbial contamination and spoilage. |

| Microwave drying | Uses controlled, rapid heating that reduces microbial load effectively and limits contamination, enhancing food safety of fruit chips by inhibiting pathogen growth. |

| Food safety comparison | Microwave drying offers superior microbial inactivation and hygienic processing conditions, while sun drying demands strict hygienic precautions and longer drying times to prevent spoilage and foodborne illnesses. |

Related Important Terms

Photodegradation

Sun drying exposes fruit chips to prolonged ultraviolet (UV) radiation, accelerating photodegradation and causing significant loss of antioxidants and vitamin C. Microwave drying minimizes light exposure, reducing photodegradation and better preserving nutritional quality and color stability in fruit chips.

Flash evaporation

Sun drying of fruit chips relies on slow evaporation under ambient conditions, leading to extended dehydration times and potential nutrient loss, whereas microwave drying utilizes rapid flash evaporation through high-frequency waves, significantly reducing drying time and better preserving flavor and nutritional content. The intense localized heating in microwave drying causes water molecules to vaporize quickly, minimizing enzymatic reactions and microbial growth compared to the gradual moisture removal in sun drying.

Microstructure retention

Sun drying preserves the natural microstructure of fruit chips by gently removing moisture at low temperatures, maintaining cellular integrity and texture. Microwave drying rapidly reduces water content while minimizing structural collapse, resulting in fruit chips with better retention of porous microstructure and enhanced crispness.

Volatile flavor preservation

Sun drying preserves some volatile flavor compounds in fruit chips but often leads to significant losses due to prolonged exposure to heat and air. Microwave drying rapidly removes moisture while better retaining delicate volatile aromatics, enhancing the overall flavor profile of the fruit chips.

Polyphenol loss

Sun drying of fruit chips typically results in higher polyphenol loss due to prolonged exposure to light and oxygen, leading to nutrient degradation. Microwave drying preserves polyphenols more effectively by rapidly reducing moisture content with minimal thermal damage and oxidation.

Texture crispness index

Sun drying fruit chips results in a lower texture crispness index due to uneven moisture removal and longer exposure times, causing softer and less crunchy chips. Microwave drying enhances the texture crispness index by rapidly reducing moisture content uniformly, producing fruit chips with a consistent, crisp, and desirable texture.

Uniformity coefficient

Sun drying yields a lower uniformity coefficient in fruit chips due to uneven exposure to sunlight and variable ambient conditions, causing inconsistent moisture removal. Microwave drying achieves a higher uniformity coefficient by applying rapid, volumetric heating, ensuring consistent dehydration and uniform texture throughout the fruit chips.

Enzymatic browning inhibition

Sun drying fruit chips slows enzymatic browning due to gradual moisture reduction but may allow prolonged enzyme activity. Microwave drying rapidly inactivates polyphenol oxidase enzymes, effectively inhibiting enzymatic browning and preserving color and nutritional quality.

Energy input efficiency

Sun drying fruit chips relies on solar energy, resulting in minimal operational costs but requires extended drying times and is weather-dependent, limiting efficiency. Microwave drying consumes higher energy input per unit time but significantly reduces drying duration, leading to increased overall energy efficiency in controlled environments.

Sun drying vs Microwave drying for fruit chips. Infographic

cookingdiff.com

cookingdiff.com