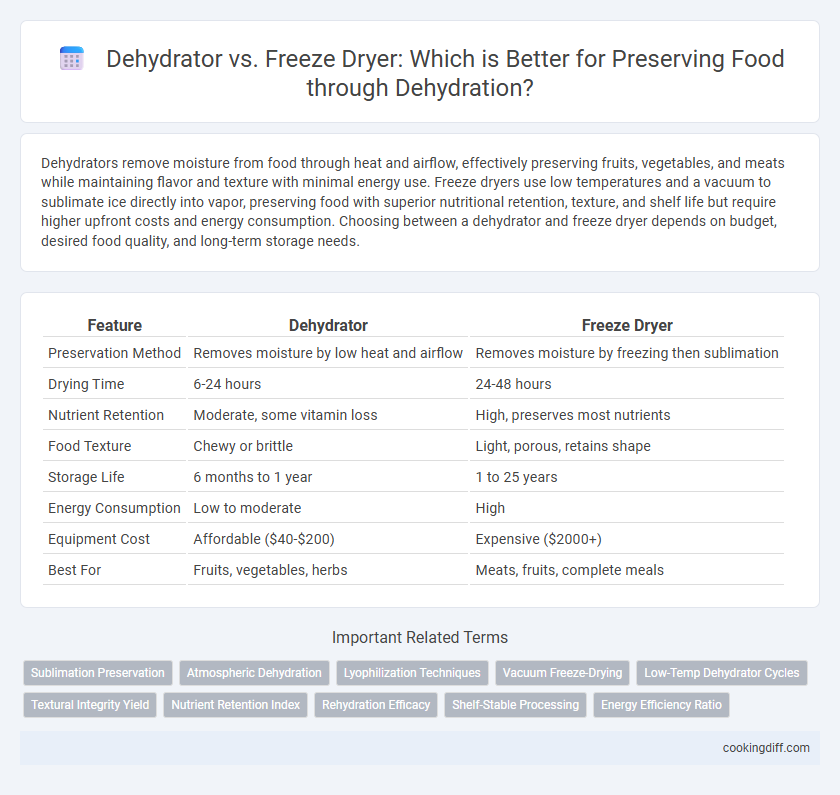

Dehydrators remove moisture from food through heat and airflow, effectively preserving fruits, vegetables, and meats while maintaining flavor and texture with minimal energy use. Freeze dryers use low temperatures and a vacuum to sublimate ice directly into vapor, preserving food with superior nutritional retention, texture, and shelf life but require higher upfront costs and energy consumption. Choosing between a dehydrator and freeze dryer depends on budget, desired food quality, and long-term storage needs.

Table of Comparison

| Feature | Dehydrator | Freeze Dryer |

|---|---|---|

| Preservation Method | Removes moisture by low heat and airflow | Removes moisture by freezing then sublimation |

| Drying Time | 6-24 hours | 24-48 hours |

| Nutrient Retention | Moderate, some vitamin loss | High, preserves most nutrients |

| Food Texture | Chewy or brittle | Light, porous, retains shape |

| Storage Life | 6 months to 1 year | 1 to 25 years |

| Energy Consumption | Low to moderate | High |

| Equipment Cost | Affordable ($40-$200) | Expensive ($2000+) |

| Best For | Fruits, vegetables, herbs | Meats, fruits, complete meals |

Introduction to Food Preservation: Dehydrating vs Freeze Drying

What are the primary differences between dehydrators and freeze dryers in food preservation? Dehydrators remove moisture through low heat and airflow, effectively reducing weight and volume for storage. Freeze dryers use sublimation to preserve food texture and nutrients by freezing and extracting water vapor in a vacuum environment.

How Dehydrators Work: Process and Technology

Dehydrators preserve food by removing moisture through controlled heat and airflow, which inhibits microbial growth and enzymatic activity. This process typically uses a low temperature to gently dry food while retaining most nutrients and texture.

- Heat Application - Dehydrators use electric heating elements to raise the temperature gradually, facilitating moisture evaporation without cooking the food.

- Air Circulation - Built-in fans circulate warm air evenly around the food, speeding up the drying process and preventing spoilage.

- Temperature Control - Adjustable thermostats ensure optimal drying conditions suited for various food types to maximize preservation and quality.

How Freeze Dryers Operate: Process and Technology

Freeze dryers operate by first freezing the food to solidify moisture, then reducing the surrounding pressure to allow the ice to sublimate directly from solid to vapor. This process utilizes a vacuum chamber and controlled heat, preserving the food's structure, nutrients, and flavor more effectively than traditional heat-based dehydration. The technology enables long-term preservation with minimal nutrient loss, making it superior for sensitive foods compared to standard dehydrators.

Nutritional Retention: Dehydrator vs Freeze Dryer

Freeze dryers preserve up to 97% of nutrients in food by removing moisture through sublimation at low temperatures, maintaining vitamins, minerals, and antioxidants more effectively than dehydrators. Dehydrators use heat to evaporate water, which can degrade heat-sensitive nutrients like vitamin C and B vitamins.

Although dehydrators are more affordable and faster, freeze drying provides superior long-term nutritional retention and flavor preservation. Freeze-dried foods retain a porous texture that allows rehydration with minimal nutrient loss, making them ideal for preserving perishables.

Texture and Taste: Comparing Dehydrated and Freeze-Dried Foods

Dehydrated foods tend to have a chewier texture and more concentrated flavors due to moisture removal through heat. Freeze-dried foods preserve the original texture more closely, maintaining a lighter, crispier bite and often a fresher taste.

- Dehydrator Texture - Results in a denser, sometimes tougher consistency because of gradual moisture loss.

- Freeze Dryer Texture - Retains porous structure, leading to a crunchy and airy mouthfeel.

- Flavor Intensity - Dehydration caramelizes sugars slightly, enhancing sweetness but altering original taste.

Freeze drying generally preserves both texture and taste better compared to dehydration, though it requires more advanced equipment.

Shelf Life: Which Method Preserves Food Longer?

Freeze dryers preserve food significantly longer than dehydrators by removing moisture at subzero temperatures, which inhibits microbial growth and enzymatic activity more effectively. Shelf life of freeze-dried foods can reach 25 years or more, while dehydrated foods typically last 1 to 2 years when stored properly.

Dehydrators use heat to evaporate water, which can degrade nutrients and lead to a shorter shelf life. Freeze drying maintains food structure and nutrients better by sublimating ice directly into vapor, preserving flavor and nutritional content. For long-term storage, freeze drying is the superior method, offering extended preservation without the need for refrigeration.

Cost Analysis: Upfront and Ongoing Expenses

| Equipment Type | Upfront Cost | Ongoing Expenses |

|---|---|---|

| Dehydrator | $40 - $300 for home models, $500+ for commercial units | Low energy consumption, occasional replacement of trays or heating elements |

| Freeze Dryer | $2,000 - $15,000 depending on capacity and brand | High energy usage, maintenance costs including vacuum pump oil changes and part replacements |

Storage Requirements: Space and Packaging Needs

Dehydrators require significantly less storage space than freeze dryers, as dried foods are compact and shelf-stable without refrigeration. Packaging for dehydrated food typically involves airtight bags or containers to prevent moisture absorption and extend shelf life.

Freeze-dried products maintain more volume and require vacuum-sealed packaging to preserve texture and nutrition, occupying more storage space overall. Proper storage for freeze-dried food demands rigid, moisture-proof containers, often increasing space and cost considerations compared to dehydrated food.

Best Foods for Dehydrating vs Freeze Drying

Dehydrators are ideal for preserving fruits like apples, bananas, and apricots, as well as vegetables such as kale and tomatoes, due to their ability to remove moisture slowly and maintain chewy textures. Freeze dryers excel with delicate foods like berries, herbs, and cooked meats, preserving nutritional content and texture by freezing and then sublimating moisture under vacuum. Choosing between dehydrating and freeze drying depends on the food type and desired shelf life, with freeze drying offering longer preservation and better rehydration quality for complex meals.

Related Important Terms

Sublimation Preservation

Freeze dryers preserve food by sublimation, converting ice directly into vapor without passing through the liquid phase, which retains nutrients, flavor, and texture more effectively than dehydrators. Dehydrators remove moisture through evaporation using heat, which can degrade certain vitamins and alter food texture, making freeze drying a superior method for long-term preservation through sublimation.

Atmospheric Dehydration

Atmospheric dehydration removes moisture from food by circulating heated air at temperatures typically between 120degF and 160degF, resulting in a shelf-stable product with concentrated flavors and reduced microbial growth. Unlike freeze drying, which preserves cellular structure by sublimation under vacuum and low temperatures, atmospheric dehydration can cause some nutrient loss and texture changes but requires less specialized equipment and lower energy consumption.

Lyophilization Techniques

Lyophilization techniques in freeze drying preserve food by removing moisture through sublimation, maintaining cellular structure and nutrients better than traditional dehydrators, which use heat to evaporate water and can degrade texture and flavor. Freeze dryers offer superior long-term preservation and rehydration quality, making them ideal for delicate foods and nutrient retention compared to conventional dehydration methods.

Vacuum Freeze-Drying

Vacuum freeze-drying preserves food by removing moisture through sublimation under low temperature and vacuum conditions, retaining nutrients, texture, and flavor more effectively than traditional dehydrators. This method extends shelf life significantly while maintaining food quality, making it superior for long-term preservation compared to conventional dehydration techniques.

Low-Temp Dehydrator Cycles

Low-temp dehydrator cycles operate typically between 95degF and 125degF, preserving nutrient integrity and enzyme activity by gently removing moisture without cooking the food. Unlike freeze dryers, which use sublimation to freeze and remove water, low-temp dehydrators offer a cost-effective method for drying herbs, fruits, and vegetables while maintaining texture and flavor.

Textural Integrity Yield

Dehydrators reduce moisture by evaporation, often resulting in tougher, shrunken textures and lower yield due to product shrinkage and brittleness, whereas freeze dryers preserve food by sublimation, maintaining cellular structure and bulk, thus ensuring superior textural integrity and higher rehydration yield. Freeze drying retains up to 97% of the original volume and texture, making it ideal for preserving delicate foods with minimal quality loss compared to dehydrating.

Nutrient Retention Index

Dehydrators typically maintain a Nutrient Retention Index (NRI) of around 50-70%, as the heat and prolonged drying process can degrade some vitamins and enzymes. Freeze dryers achieve a higher NRI, often exceeding 90%, by preserving cellular structure through sublimation, which retains most nutrients and flavor compounds more effectively than dehydrators.

Rehydration Efficacy

Dehydrators remove moisture from food through heat, resulting in a tougher texture that may absorb water slowly during rehydration, often requiring extended soaking times. Freeze dryers remove moisture by sublimation, preserving cell structure and nutrients, which enables rapid and more complete rehydration, maintaining the food's original texture and flavor more effectively.

Shelf-Stable Processing

Dehydrators reduce food moisture to about 10-20%, creating shelf-stable products by inhibiting microbial growth, while freeze dryers remove up to 98-99% of water through sublimation, preserving texture, flavor, and nutritional content with extended shelf life. Freeze drying offers superior shelf-stable processing by maintaining cellular integrity and preventing oxidation, making it ideal for long-term food storage compared to conventional dehydration.

Dehydrator vs Freeze dryer for preserving food Infographic

cookingdiff.com

cookingdiff.com