Air drying herbs preserves their natural flavor through slow moisture evaporation but takes several days and is affected by environmental conditions. Infrared dehydrators use targeted heat waves to rapidly remove moisture, maintaining herbs' color and potency while reducing drying time significantly. Choosing between the two methods depends on prioritizing speed and consistency versus traditional, energy-free processing.

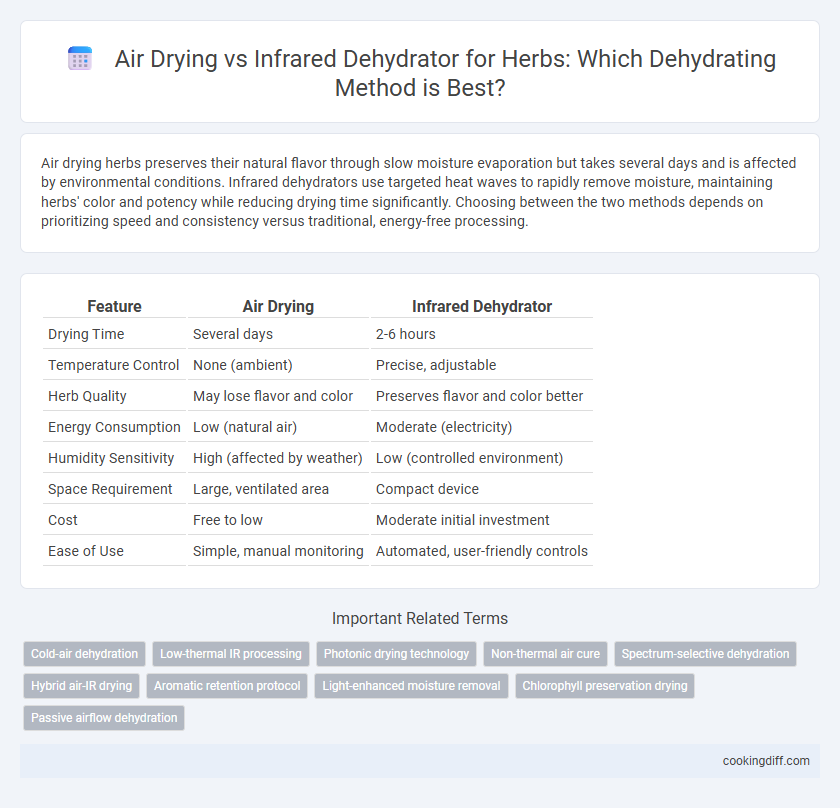

Table of Comparison

| Feature | Air Drying | Infrared Dehydrator |

|---|---|---|

| Drying Time | Several days | 2-6 hours |

| Temperature Control | None (ambient) | Precise, adjustable |

| Herb Quality | May lose flavor and color | Preserves flavor and color better |

| Energy Consumption | Low (natural air) | Moderate (electricity) |

| Humidity Sensitivity | High (affected by weather) | Low (controlled environment) |

| Space Requirement | Large, ventilated area | Compact device |

| Cost | Free to low | Moderate initial investment |

| Ease of Use | Simple, manual monitoring | Automated, user-friendly controls |

Introduction to Herb Dehydration Methods

| Air drying is a traditional herb dehydration method that relies on natural airflow and ambient temperature to remove moisture, preserving essential oils and flavors without overheating the herbs. |

| Infrared dehydrators utilize infrared radiation to efficiently and evenly extract moisture from herbs, reducing drying time and maintaining nutrient integrity. |

| Both methods offer unique benefits depending on herb type, drying speed requirements, and desired quality outcomes in culinary or medicinal applications. |

Understanding Air Drying for Herbs

Air drying herbs involves hanging the bundles in a well-ventilated, dry environment with low humidity to preserve essential oils and flavor. This traditional method can take several days to weeks, depending on the herb type and ambient conditions. Infrared dehydrators, by contrast, use radiant heat to speed up moisture removal while maintaining herb quality but may alter some delicate compounds.

Exploring Infrared Dehydrators

Infrared dehydrators use wavelength-specific heat to efficiently remove moisture from herbs, preserving their essential oils and enhancing flavor retention better than traditional air drying methods. This technology shortens drying time, reducing the risk of microbial growth and oxidation that can occur during prolonged air drying.

Herbs dried with infrared dehydrators maintain higher nutrient content and color vibrancy, making them ideal for culinary and medicinal uses. Compared to air drying, infrared dehydrators provide consistent temperature control, ensuring uniform dehydration for bulk herb processing.

Key Differences: Air Drying vs Infrared Dehydration

Air drying herbs relies on natural airflow and ambient temperature, preserving essential oils but requiring several days for complete dehydration. Infrared dehydrators use targeted infrared heat to rapidly remove moisture, reducing drying time while maintaining herb color and potency.

Air drying is energy-efficient and cost-effective but is susceptible to mold if humidity is high. Infrared dehydration offers precise temperature control and uniform drying, minimizing nutrient loss and bacterial growth risks during the process.

Preservation of Nutrients in Herbs

Air drying herbs preserves nutrients slowly by using natural airflow and ambient temperatures, minimizing nutrient loss. Infrared dehydrators use controlled heat and infrared radiation, which can better retain essential oils and antioxidants while speeding up drying time.

- Air drying preserves delicate nutrients - The gentle, low-temperature process reduces degradation of heat-sensitive vitamins.

- Infrared dehydrators enhance antioxidant retention - Infrared waves penetrate plant tissues, helping to maintain flavonoids and phenolic compounds.

- Infrared drying reduces microbial content - The faster drying process lowers the risk of mold and bacterial growth during dehydration.

Choosing between air drying and infrared dehydrators depends on balancing preservation of nutrients with desired drying speed and quality.

Flavor and Aroma Retention

Air drying herbs preserves their natural flavor and aroma over time through a slow evaporation process that minimizes heat exposure, thus maintaining essential oils. Infrared dehydrators use targeted heat wavelengths to speed up drying but may degrade some delicate aromatic compounds, slightly altering the herb's original scent and taste. Optimal retention of flavor and aroma depends on the herb type, with air drying favored for fragile leaves like basil and infrared dehydrators better suited for robust herbs such as rosemary.

Speed and Efficiency Comparison

Air drying herbs is a traditional method that relies on ambient air circulation, resulting in slower dehydration times often spanning several days. Infrared dehydrators accelerate the drying process by using infrared radiation to penetrate herb tissues, significantly reducing drying times and improving energy efficiency.

- Speed - Infrared dehydrators can dry herbs in a few hours compared to the several days required for air drying.

- Energy Efficiency - Infrared technology targets moisture directly, using less energy than prolonged air drying which depends on ambient conditions.

- Quality Preservation - Faster infrared drying minimizes nutrient loss and maintains herb aroma better than slow air drying.

Cost and Energy Considerations

Air drying herbs is cost-effective as it requires no special equipment and utilizes natural ambient conditions. This method incurs virtually no ongoing energy expenses, making it ideal for small-scale or hobbyist use.

Infrared dehydrators, though initially more expensive to purchase, offer faster drying times and consistent results due to controlled temperature and humidity levels. They consume electricity, which adds to operational costs, but their efficiency can reduce overall energy usage compared to prolonged air drying. For commercial or frequent use, the investment in an infrared dehydrator can lead to savings in both time and energy expenses.

Suitability for Different Herbs

Air drying is ideal for delicate herbs like basil and cilantro, preserving their texture and flavor through gentle, slow moisture removal. Infrared dehydrators suit hardy herbs such as rosemary and thyme, offering rapid drying with efficient heat penetration while maintaining essential oils.

- Air drying is best for fragile herbs - Slow drying prevents damage and preserves delicate leaf structure.

- Infrared dehydrators work well with robust herbs - Targeted heat effectively removes moisture without over-drying.

- Herb moisture content influences method choice - High-moisture herbs benefit from air drying to avoid flavor loss.

Related Important Terms

Cold-air dehydration

Cold-air dehydration using an air dryer preserves the delicate volatile oils and flavors in herbs more effectively than infrared dehydrators, which generate heat that can degrade essential compounds. Air drying maintains low temperatures, ensuring optimal retention of aroma and nutritional quality in herbs during the dehydration process.

Low-thermal IR processing

Low-thermal infrared (IR) dehydrators preserve herbs by minimizing heat exposure, maintaining essential oils and vibrant colors better than traditional air drying methods. Infrared drying significantly reduces moisture content quickly and uniformly, enhancing herb quality and shelf life with lower energy consumption.

Photonic drying technology

Air drying herbs relies on natural airflow and ambient temperature, which can take several days and may result in uneven moisture removal and loss of aromatic compounds. Infrared dehydrators utilize photonic drying technology to deliver targeted infrared radiation, accelerating moisture evaporation while preserving essential oils and color through controlled, uniform heat application.

Non-thermal air cure

Air drying herbs utilizes a non-thermal air cure process that preserves essential oils and flavor compounds by naturally dehydrating at room temperature with controlled airflow, preventing heat damage. Infrared dehydrators accelerate moisture removal using radiation heat, which can compromise delicate herb quality and reduce aromatic potency compared to traditional air drying methods.

Spectrum-selective dehydration

Air drying herbs relies on natural airflow and ambient temperature, preserving essential oils but often resulting in longer drying times and potential quality loss. Infrared dehydrators use spectrum-selective dehydration technology to target specific wavelengths that efficiently remove moisture while maintaining herb color, flavor, and nutrient retention.

Hybrid air-IR drying

Hybrid air-infrared drying combines the gentle airflow of air drying with the rapid heat transfer of infrared technology, preserving essential oils and aromatic compounds in herbs more effectively than either method alone. This innovative approach reduces drying time while maintaining color, flavor, and nutritional content, offering a superior solution for herb dehydration.

Aromatic retention protocol

Air drying preserves herbs by allowing a slow moisture evaporation process that maintains essential oil integrity, resulting in maximum aromatic retention. Infrared dehydrators offer controlled heat that accelerates drying times while minimizing the loss of volatile compounds, optimizing both flavor and fragrance stability in dried herbs.

Light-enhanced moisture removal

Air drying herbs relies on natural airflow and ambient temperature to slowly evaporate moisture, preserving delicate flavors but requiring extended time and consistent conditions. Infrared dehydrators use targeted infrared light to penetrate herb leaves, accelerating moisture removal by promoting internal water diffusion and enhancing drying efficiency without compromising herb quality.

Chlorophyll preservation drying

Air drying herbs preserves chlorophyll by slowly removing moisture at ambient temperatures, minimizing heat damage and maintaining vibrant green color. Infrared dehydrators accelerate drying through targeted heat, which can degrade chlorophyll more rapidly, potentially reducing the herb's natural color and antioxidants.

Air drying vs Infrared dehydrator for herbs Infographic

cookingdiff.com

cookingdiff.com