Microwave dehydrators heat pet food quickly by agitating water molecules, preserving nutrients while reducing drying time significantly. Infrared dehydrators use radiant heat to penetrate evenly, maintaining texture and flavor without overcooking. Choosing between them depends on desired drying speed and nutrient retention, with microwaves excelling in speed and infrared in gentle, uniform dehydration.

Table of Comparison

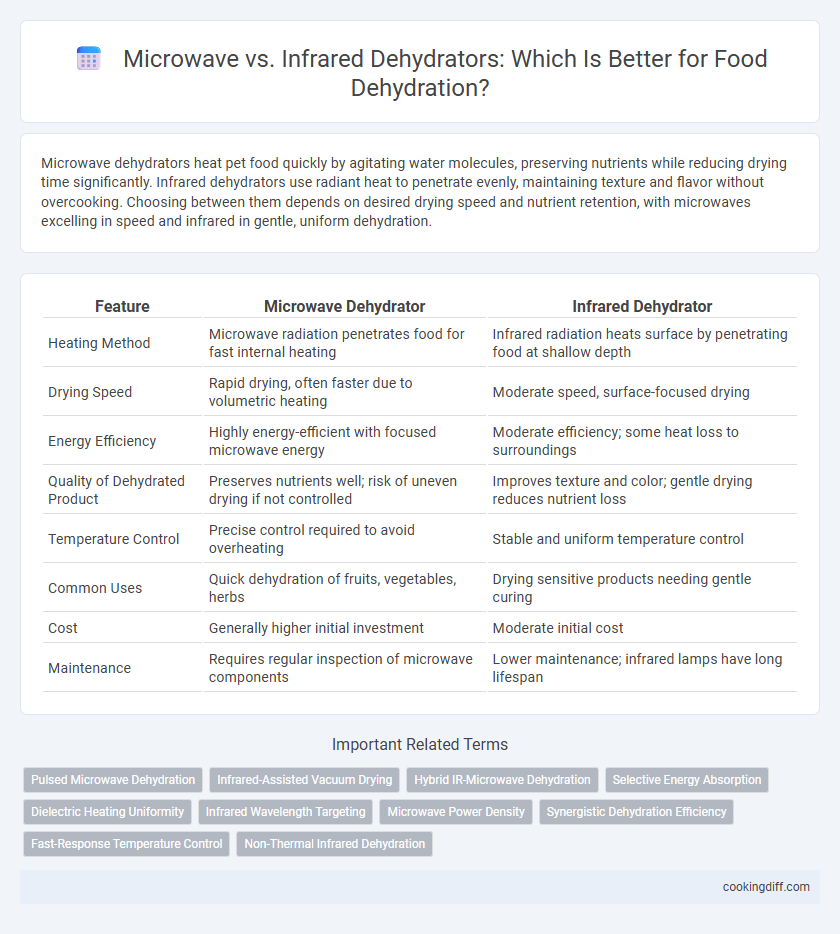

| Feature | Microwave Dehydrator | Infrared Dehydrator |

|---|---|---|

| Heating Method | Microwave radiation penetrates food for fast internal heating | Infrared radiation heats surface by penetrating food at shallow depth |

| Drying Speed | Rapid drying, often faster due to volumetric heating | Moderate speed, surface-focused drying |

| Energy Efficiency | Highly energy-efficient with focused microwave energy | Moderate efficiency; some heat loss to surroundings |

| Quality of Dehydrated Product | Preserves nutrients well; risk of uneven drying if not controlled | Improves texture and color; gentle drying reduces nutrient loss |

| Temperature Control | Precise control required to avoid overheating | Stable and uniform temperature control |

| Common Uses | Quick dehydration of fruits, vegetables, herbs | Drying sensitive products needing gentle curing |

| Cost | Generally higher initial investment | Moderate initial cost |

| Maintenance | Requires regular inspection of microwave components | Lower maintenance; infrared lamps have long lifespan |

Introduction to Microwave and Infrared Dehydrators

Microwave dehydrators use electromagnetic waves to rapidly heat and remove moisture from food, preserving nutrients and reducing drying time. Infrared dehydrators emit infrared radiation that penetrates food surfaces, providing even drying while maintaining texture and flavor. Both technologies offer efficient dehydration but differ in heat transfer methods and drying speed.

How Microwave Dehydrators Work

Microwave dehydrators use microwave radiation to rapidly heat water molecules within food, causing internal moisture to evaporate quickly. This method preserves nutrients efficiently while significantly reducing drying time compared to traditional dehydrators.

- Microwave radiation - Penetrates food to agitate water molecules, generating heat from within.

- Rapid moisture evaporation - Speeds up dehydration by drying the interior as well as the surface of the food.

- Energy efficiency - Uses less energy due to shorter operating times and focused heat application.

How Infrared Dehydrators Work

Infrared dehydrators use infrared light waves to penetrate food, causing molecules to vibrate and generate heat internally for efficient moisture removal. This method preserves nutrients and flavors better than conventional heat-based drying techniques.

- Energy Efficiency - Infrared waves directly heat the food without warming the surrounding air, reducing energy consumption.

- Even Drying - Infrared radiation penetrates deeper, ensuring uniform dehydration throughout the food item.

- Faster Process - The internal heating mechanism speeds up drying time compared to microwave and traditional dehydrators.

Infrared dehydrators are ideal for retaining food quality while speeding up the dehydration process with lower energy use.

Efficiency Comparison: Microwave vs Infrared Dehydration

| Dehydration Method | Energy Efficiency | Drying Speed | Temperature Control |

|---|---|---|---|

| Microwave Dehydrator | High energy efficiency due to direct water molecule excitation | Faster drying times, often reducing dehydration by 50% | Moderate to low precision; risk of uneven heating |

| Infrared Dehydrator | Moderate energy efficiency by surface heat radiation | Slower drying compared to microwave, suited for delicate items | Better temperature uniformity with adjustable settings |

Energy Consumption and Cost Analysis

Microwave dehydrators consume significantly less energy, averaging between 400 to 700 watts, compared to infrared dehydrators, which typically operate at 800 to 1200 watts. This lower wattage directly translates to reduced electricity bills and a smaller carbon footprint over time.

Cost analysis reveals microwave dehydrators often have a higher upfront price, ranging from $150 to $300, while infrared dehydrators can range from $100 to $250 depending on capacity and features. However, the energy savings of microwave models can offset the initial investment within a year of regular use, making them more cost-effective in the long run.

Nutrient Retention in Dehydrated Foods

Microwave dehydrators use rapid heat generation that can preserve more vitamins sensitive to prolonged heat exposure, such as vitamin C. Infrared dehydrators provide a gentle, consistent drying process that retains minerals and antioxidants effectively in dehydrated foods.

- Microwave heat intensity - Rapid heating minimizes nutrient degradation by shortening drying time.

- Infrared gentle drying - Low surface temperature helps maintain enzyme activity and antioxidant levels.

- Nutrient retention - Both methods excel in preserving different nutrient profiles based on heat application and exposure duration.

Flavor and Texture Differences

Microwave dehydrators preserve flavor by rapidly removing moisture, which minimizes nutrient loss and maintains vibrant taste profiles. Infrared dehydrators enhance texture by promoting even drying and preventing surface case hardening, resulting in chewier and more uniformly dried products. Flavor in microwave dehydration tends to be fresher, while infrared drying often intensifies aromas due to gentle heat application.

Suitability for Different Foods

Microwave dehydrators excel in rapidly removing moisture from fruits and vegetables, making them suitable for high-water-content foods but less effective for thicker or denser items. Infrared dehydrators provide consistent, gentle heat ideal for herbs, meats, and delicate items requiring uniform drying without cooking.

Foods like leafy greens and berries benefit from microwave dehydration due to quick drying times that preserve nutrients and color. Infrared dehydrators are better suited for meats or roots, as their slow, even heat prevents case hardening and maintains texture.

User Experience and Safety Considerations

Microwave dehydrators offer rapid dehydration but can cause uneven drying and hot spots, posing a risk of burns if handled improperly. Infrared dehydrators provide more uniform heat distribution, enhancing user safety by reducing the likelihood of overheating specific food areas.

Users often prefer infrared dehydrators for their consistent temperature control and lower risk of fire hazards, contributing to a smoother and safer drying process. Microwave dehydrators require careful monitoring to avoid damaging the food or causing accidents due to sudden temperature spikes. Proper ventilation and heat-resistant gloves are recommended when using either device to maximize safety and comfort during dehydration tasks.

Related Important Terms

Pulsed Microwave Dehydration

Pulsed microwave dehydration offers rapid moisture removal by utilizing intermittent microwave energy, enhancing drying efficiency compared to continuous infrared dehydrators that rely on surface heat transfer. This method reduces drying time and preserves nutritional quality by minimizing thermal degradation and uneven moisture diffusion typical in infrared dehydration.

Infrared-Assisted Vacuum Drying

Infrared-assisted vacuum drying combines infrared radiation with reduced pressure to accelerate moisture removal while preserving nutritional quality and color better than conventional microwave dehydrators. This method enhances dehydration efficiency, reduces drying time, and minimizes thermal degradation, making it ideal for heat-sensitive food products.

Hybrid IR-Microwave Dehydration

Hybrid IR-Microwave dehydration combines the rapid heating capabilities of microwaves with the uniform surface drying of infrared radiation, resulting in faster moisture removal and improved product quality compared to using either method alone. This synergistic approach enhances energy efficiency and preserves nutritional content, making it ideal for industrial-scale dehydrating applications.

Selective Energy Absorption

Microwave dehydrators utilize selective energy absorption by targeting water molecules directly, resulting in faster moisture removal with reduced heat damage to nutrients. Infrared dehydrators rely on radiant heat absorption by the food's surface, which may cause uneven drying and longer processing times compared to microwave technology.

Dielectric Heating Uniformity

Microwave dehydrators utilize dielectric heating to penetrate food uniformly, resulting in faster and more consistent moisture removal compared to infrared dehydrators, which primarily heat the surface and rely on conduction for internal drying. This uniform dielectric heating minimizes uneven dehydration and preserves nutrient quality more effectively in microwave drying processes.

Infrared Wavelength Targeting

Infrared dehydrators utilize wavelengths typically between 700 nm and 1 mm, which directly target water molecules within food, enabling efficient heat penetration and faster moisture removal without compromising nutritional content. This precise wavelength targeting contrasts with microwaves that use 2.45 GHz frequencies, primarily agitating water molecules volumetrically but often leading to uneven dehydration and potential nutrient loss.

Microwave Power Density

Microwave dehydrators operate with a high microwave power density that enables rapid internal heating by agitating water molecules, leading to faster moisture removal compared to infrared dehydrators, which rely on surface heating through radiation. This concentrated microwave power density improves energy efficiency and reduces dehydration time, but may require precise control to prevent uneven drying or overheating.

Synergistic Dehydration Efficiency

Microwave dehydrators rapidly remove moisture by exciting water molecules, preserving nutrients and reducing drying time, while infrared dehydrators use heat radiation to penetrate food evenly, preventing surface hardening and enhancing flavor retention. Combining microwave and infrared technologies creates a synergistic dehydration efficiency that optimizes drying speed, uniformity, and energy consumption for superior food preservation.

Fast-Response Temperature Control

Microwave dehydrators offer fast-response temperature control by quickly adjusting energy output, ensuring precise moisture removal without overheating delicate food items. Infrared dehydrators rely on radiant heat for steady temperature maintenance but respond slower to temperature changes, making them less efficient for rapid dehydration cycles.

Microwave vs Infrared dehydrator for dehydrating. Infographic

cookingdiff.com

cookingdiff.com