Air drying jerky relies on natural airflow and ambient temperatures, which can be inconsistent and increase the risk of uneven drying or bacterial growth. Low-temperature dehydrators provide controlled heat and airflow, ensuring consistent moisture removal and safer preservation. Using a dehydrator optimizes texture, flavor, and shelf life for high-quality jerky.

Table of Comparison

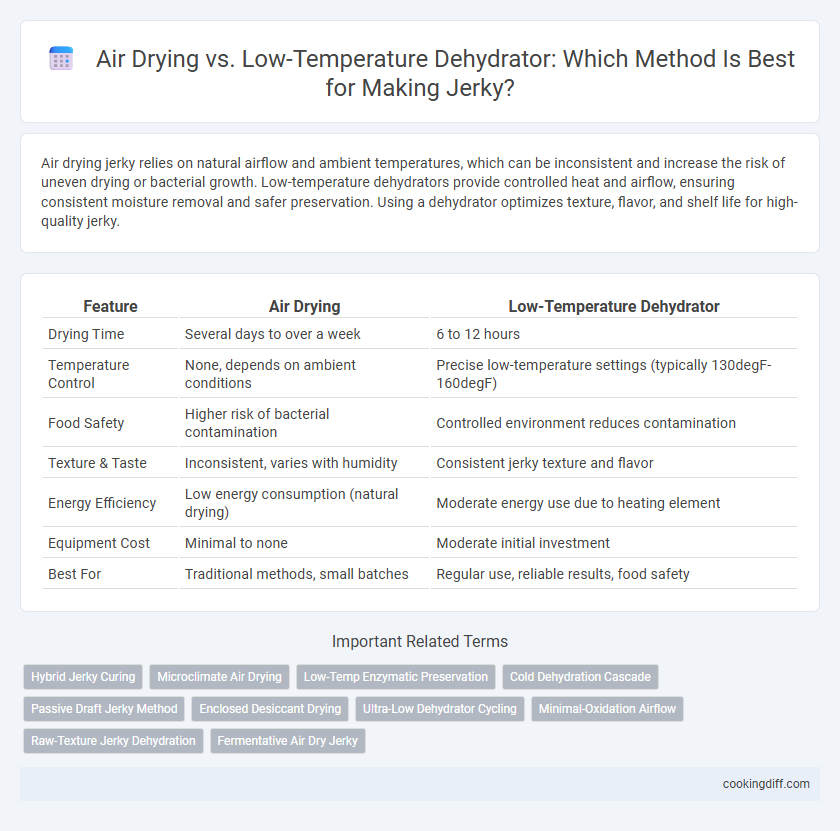

| Feature | Air Drying | Low-Temperature Dehydrator |

|---|---|---|

| Drying Time | Several days to over a week | 6 to 12 hours |

| Temperature Control | None, depends on ambient conditions | Precise low-temperature settings (typically 130degF-160degF) |

| Food Safety | Higher risk of bacterial contamination | Controlled environment reduces contamination |

| Texture & Taste | Inconsistent, varies with humidity | Consistent jerky texture and flavor |

| Energy Efficiency | Low energy consumption (natural drying) | Moderate energy use due to heating element |

| Equipment Cost | Minimal to none | Moderate initial investment |

| Best For | Traditional methods, small batches | Regular use, reliable results, food safety |

Introduction: Choosing the Best Jerky Dehydration Method

Air drying and low-temperature dehydrators are popular methods for jerky dehydration, each offering unique benefits. Air drying relies on natural airflow and ambient temperature, while low-temperature dehydrators use controlled heat settings for consistent results.

The choice between these methods impacts texture, flavor, and preservation of jerky. Understanding the advantages of air drying versus low-temperature dehydration helps in selecting the most effective technique for safe and delicious jerky production.

Overview of Air Drying Jerky: Traditional Techniques

Air drying jerky is a traditional preservation method that relies on natural airflow and ambient temperature to remove moisture from meat. This technique requires careful control of humidity and cleanliness to prevent spoilage and ensure safe drying.

- Natural airflow - Jerky dries slowly as air circulates around the meat, aiding moisture evaporation without using artificial heat.

- Environmental factors - Successful air drying depends heavily on low humidity, moderate temperatures, and protection from insects.

- Time-intensive process - Drying jerky by air can take several days, requiring constant monitoring to avoid bacterial growth.

Low-Temperature Dehydrators: Modern Efficiency Explained

Low-temperature dehydrators maintain consistent heat levels between 130degF and 160degF, ensuring jerky dries evenly without cooking the meat. This controlled environment preserves flavor and nutrients while reducing the risk of bacterial growth during dehydration.

Modern low-temperature dehydrators feature adjustable thermostats and airflow mechanisms that enhance drying efficiency and energy use. These innovations make them a superior choice over traditional air drying by providing uniform results and shorter drying times.

Flavor Differences: Air Dried vs Dehydrator Jerky

How does the flavor of air dried jerky compare to jerky made with a low-temperature dehydrator? Air drying jerky imparts a natural, smoky flavor with subtle variations due to environmental factors, whereas low-temperature dehydrators offer consistent heat that enhances the meat's inherent flavors without overcooking. Dehydrator jerky typically has a more uniform texture and concentrated taste, making it preferred for controlled flavor profiles.

Food Safety Considerations in Both Methods

| Air drying jerky at ambient temperatures risks uneven dehydration, allowing bacteria like Salmonella and E. coli to survive, compromising food safety. Low-temperature dehydrators maintain consistent heat, typically between 130degF and 160degF (54degC to 71degC), ensuring thorough moisture removal and pathogen reduction according to USDA guidelines. Proper internal jerky temperature monitoring and drying duration are critical in both methods to prevent microbial contamination and ensure safe consumption. |

Texture and Appearance: Comparing Results

Air drying jerky produces a chewier texture with a slightly uneven surface due to natural airflow and slower moisture removal. Low-temperature dehydrators offer a more uniform texture and consistent appearance by controlling drying conditions precisely.

Air drying can result in darker, sometimes patchy coloration influenced by ambient humidity and temperature fluctuations. Dehydrators maintain a consistent low heat that enhances the jerky's color uniformity and reduces the risk of over-drying or spoilage. Both methods affect the jerky's shelf life and tenderness, but dehydrators provide greater control over final product quality.

Equipment and Setup Requirements

Air drying jerky requires minimal equipment, typically just a clean, ventilated space and hanging racks, making it a low-cost option but dependent on environmental conditions. Low-temperature dehydrators offer precise temperature control and consistent airflow, ensuring even drying and food safety with digital or analog settings. Setup for dehydrators involves plug-in power sources and adjustable trays designed for airflow optimization, providing a more controlled and efficient drying process compared to traditional air drying.

Energy Consumption and Cost Analysis

Air drying jerky utilizes natural airflow and ambient temperature, resulting in minimal energy consumption and near-zero operational costs. Low-temperature dehydrators consume electricity consistently, leading to higher energy expenses but offering controlled drying conditions.

- Energy Efficiency - Air drying requires no electrical input, maximizing energy savings compared to dehydrators.

- Cost of Operation - Dehydrators incur ongoing electricity costs that vary based on usage duration and power rating.

- Drying Consistency - Dehydrators provide uniform temperature control, potentially reducing waste and improving quality despite higher energy use.

Choosing between air drying and low-temperature dehydrators involves balancing energy savings with product consistency and drying time.

Time Commitment: Air Drying vs Dehydrator Speeds

Air drying jerky requires several days depending on environmental conditions, making it a lengthy process with less consistent results. Low-temperature dehydrators significantly reduce drying time by maintaining steady heat, typically finishing in 6 to 12 hours.

- Air Drying Duration - Takes 2 to 5 days influenced by humidity and airflow, impacting jerky texture and safety.

- Dehydrator Speed Efficiency - Operates at controlled temperatures around 130degF, accelerating drying while preventing spoilage.

- Time Commitment Comparison - Dehydrators offer predictable timing, ideal for efficient jerky production over the variable air drying method.

Related Important Terms

Hybrid Jerky Curing

Hybrid jerky curing combines air drying and low-temperature dehydrator methods to optimize moisture removal while preserving flavor and texture integrity. Utilizing controlled airflow and precise temperature regulation around 130degF enhances microbial safety and ensures uniform drying without overcooking.

Microclimate Air Drying

Microclimate air drying creates a controlled environment with optimal humidity and airflow, enhancing the safety and consistency of jerky dehydration compared to traditional air drying. Low-temperature dehydrators maintain steady heat and ventilation, but microclimate techniques use natural air currents and moisture control for superior flavor and texture preservation.

Low-Temp Enzymatic Preservation

Low-temperature dehydrators preserve jerky by maintaining enzymatic activity, which enhances flavor retention and nutrient preservation compared to traditional air drying. This method reduces oxidation and microbial growth, ensuring a safer, higher-quality jerky with extended shelf life.

Cold Dehydration Cascade

Cold dehydration cascade in air drying preserves jerky's flavor and nutrients by gradually lowering temperatures to below 40degF, preventing bacterial growth without cooking. Low-temperature dehydrators maintain consistent heat around 130degF, ensuring moisture removal but risking slight nutrient degradation compared to the cold cascade's gentle preservation.

Passive Draft Jerky Method

Passive draft jerky drying relies on natural airflow and ambient temperature, making it an energy-efficient method but slower and potentially less consistent than low-temperature dehydrators. Low-temperature dehydrators maintain a controlled environment with steady heat around 130degF (54degC), ensuring safer, faster, and more uniform jerky dehydration.

Enclosed Desiccant Drying

Enclosed desiccant drying enhances air drying by absorbing moisture within a sealed environment, reducing drying time and improving jerky shelf life without heat damage. Low-temperature dehydrators maintain consistent temperatures around 130degF, preserving meat texture and safety but use more energy compared to passive desiccant air drying methods.

Ultra-Low Dehydrator Cycling

Ultra-low dehydrator cycling in air drying jerky minimizes temperature fluctuations, preserving meat texture and preventing bacterial growth more effectively compared to traditional low-temperature dehydrators. This precise temperature control enhances moisture removal efficiency while maintaining safety standards critical for jerky preservation.

Minimal-Oxidation Airflow

Air drying jerky utilizes natural airflow with minimal oxidation, preserving flavor and color by reducing exposure to oxygen compared to low-temperature dehydrators that circulate heated air and can accelerate oxidation. Minimal-oxidation airflow in air drying helps maintain nutrient integrity and prevents rancidity, whereas low-temperature dehydrators run a higher risk of lipid degradation despite controlled temperatures.

Raw-Texture Jerky Dehydration

Air drying raw-texture jerky relies on ambient conditions, which can result in uneven moisture removal and longer dehydration times, potentially compromising food safety and texture consistency. Low-temperature dehydrators provide controlled heat and airflow, ensuring uniform drying that preserves the jerky's natural chewiness while reducing bacterial risk during the dehydration process.

Air Drying vs Low-Temperature Dehydrator for Jerky Infographic

cookingdiff.com

cookingdiff.com