Plastic tray dehydrators are lightweight, cost-effective, and resistant to corrosion, making them a popular choice for drying mushrooms. Stainless steel tray dehydrators offer superior durability, easy cleaning, and excellent heat distribution, which helps maintain mushroom quality during dehydration. Choosing between the two depends on balancing budget constraints with the desired longevity and hygiene standards for mushroom preservation.

Table of Comparison

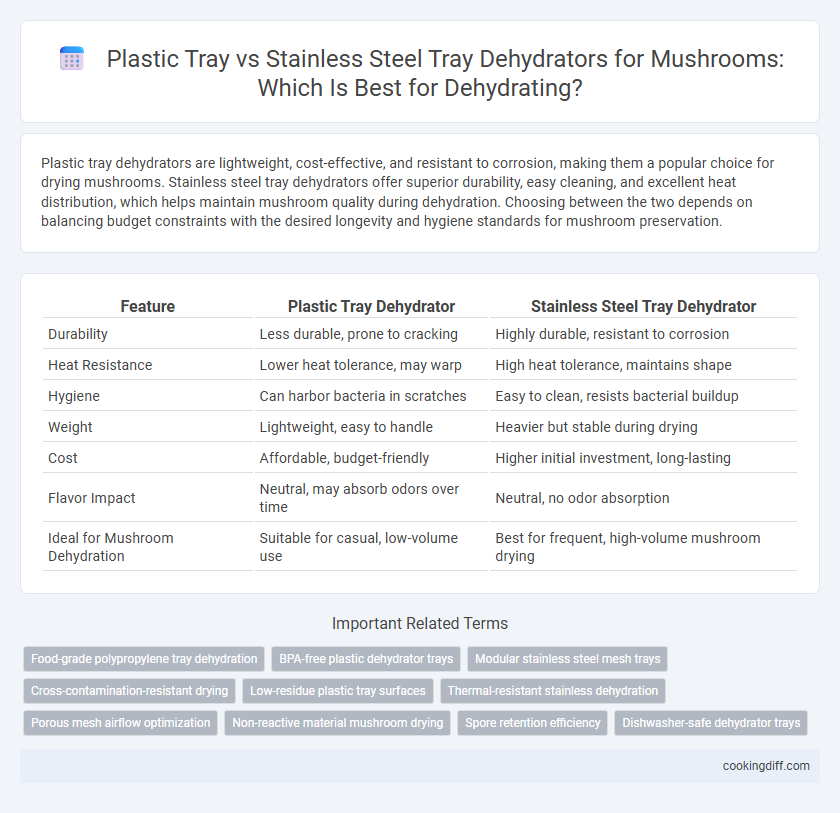

| Feature | Plastic Tray Dehydrator | Stainless Steel Tray Dehydrator |

|---|---|---|

| Durability | Less durable, prone to cracking | Highly durable, resistant to corrosion |

| Heat Resistance | Lower heat tolerance, may warp | High heat tolerance, maintains shape |

| Hygiene | Can harbor bacteria in scratches | Easy to clean, resists bacterial buildup |

| Weight | Lightweight, easy to handle | Heavier but stable during drying |

| Cost | Affordable, budget-friendly | Higher initial investment, long-lasting |

| Flavor Impact | Neutral, may absorb odors over time | Neutral, no odor absorption |

| Ideal for Mushroom Dehydration | Suitable for casual, low-volume use | Best for frequent, high-volume mushroom drying |

Introduction: Why Dehydrate Mushrooms?

| Mushroom dehydration preserves flavor, nutritional value, and extends shelf life by reducing moisture content below 10% to prevent microbial growth, favoring both plastic and stainless steel trays. Plastic trays offer lightweight, cost-effective solutions with good airflow but risk chemical leaching under high heat, while stainless steel trays provide durability, non-reactivity, and excellent heat conduction, ideal for maintaining mushroom quality during dehydration. Choosing the right tray impacts drying efficiency, texture retention, and overall mushroom preservation in commercial or home settings. |

Overview of Plastic Tray Dehydrators

Plastic tray dehydrators are lightweight and generally more affordable options for drying mushrooms, offering ease of handling and storage. They may retain moisture longer than stainless steel, potentially impacting drying speed and mold risk.

- Cost-Effective - Plastic trays are less expensive, making them accessible for home use and small-scale operations.

- Lightweight Design - Easier to maneuver and store compared to heavier stainless steel trays.

- Moisture Retention - Plastic can trap moisture, which may slow drying and increase the chance of mold growth.

Overview of Stainless Steel Tray Dehydrators

Stainless steel tray dehydrators offer superior durability and resistance to corrosion compared to plastic tray models, making them ideal for long-term use in mushroom drying. Their non-reactive surface ensures no contamination or flavor alteration during the dehydration process.

These dehydrators provide even heat distribution and maintain consistent airflow, which is critical for preserving the texture and nutritional quality of mushrooms. Stainless steel trays withstand higher temperatures without warping, supporting efficient moisture removal. Easy to clean and sanitize, they comply with food safety standards essential for commercial mushroom drying operations.

Durability: Plastic vs Stainless Steel Trays

Stainless steel trays offer superior durability compared to plastic trays, resisting warping and cracking under high heat during mushroom dehydration. Plastic trays may degrade over time from heat exposure and are prone to bending or breaking, which can affect the drying process.

- Heat Resistance - Stainless steel can withstand prolonged high temperatures without compromising structural integrity.

- Longevity - Stainless steel trays maintain their shape and performance after repeated use over years.

- Maintenance - Plastic trays are more susceptible to staining and can harbor odors from mushrooms, reducing their functional lifespan.

Stainless steel trays are the optimal choice for long-term durability and consistent mushroom dehydration results.

Food Safety and Material Reactivity

Stainless steel tray dehydrators offer superior food safety due to their non-porous, corrosion-resistant surface that prevents bacterial growth and chemical leaching during the dehydration of mushrooms. Plastic tray dehydrators, while lightweight and affordable, may pose risks of chemical contamination and can degrade over time with heat exposure.

- Non-reactive Surface - Stainless steel trays do not react with mushroom compounds, ensuring purity and safety in the drying process.

- Chemical Stability - Plastic trays risk releasing harmful substances when heated, potentially contaminating the mushrooms.

- Durability and Hygiene - Stainless steel is easier to sanitize and withstands prolonged heat without structural breakdown compared to plastic.

Airflow and Drying Consistency

Plastic tray dehydrators often have less efficient airflow compared to stainless steel tray dehydrators, which can result in uneven drying of mushrooms. Stainless steel trays promote better air circulation due to their rigid structure and perforation design, enhancing drying consistency.

The material of stainless steel trays withstands higher temperatures without warping, ensuring consistent heat distribution throughout the drying process. Plastic trays may retain moisture and heat unevenly, leading to variable drying times and potential mold growth in mushrooms.

Ease of Cleaning and Maintenance

Stainless steel tray dehydrators offer superior ease of cleaning due to their non-porous surfaces that resist staining and do not retain odors from mushrooms. Plastic tray dehydrators are more prone to scratches and can absorb odors, making thorough cleaning more challenging and increasing maintenance efforts. Choosing stainless steel trays reduces long-term maintenance time and ensures a more hygienic drying process for mushrooms.

Cost Comparison: Plastic vs Stainless Steel

Plastic tray dehydrators generally have a lower upfront cost compared to stainless steel tray dehydrators, making them more budget-friendly for small-scale mushroom drying. Stainless steel trays, while more expensive initially, offer greater durability and resistance to corrosion, potentially reducing replacement costs over time. When factoring in longevity and maintenance, stainless steel tray dehydrators often provide better value for commercial mushroom growers despite the higher initial investment.

Impact on Mushroom Flavor and Texture

Plastic tray dehydrators tend to retain more moisture during the drying process, which can result in mushrooms with a softer texture but less concentrated flavor. Stainless steel tray dehydrators promote better air circulation and even heat distribution, helping to preserve the mushroom's natural umami and firmness.

The choice of tray material directly impacts the final quality of dried mushrooms, with stainless steel trays enhancing flavor intensity and creating a chewier texture preferred in culinary uses. Plastic trays may cause slight off-flavors due to potential odor absorption and slower drying times, affecting overall mushroom taste and texture.

Related Important Terms

Food-grade polypropylene tray dehydration

Food-grade polypropylene trays in dehydrators offer superior moisture resistance and flexibility compared to stainless steel trays, making them ideal for gently drying mushrooms without risking metallic contamination or flavor alteration. Polypropylene's non-porous surface prevents mold growth and facilitates easy cleaning, ensuring a hygienic environment that preserves the mushrooms' nutritional value and aroma during dehydration.

BPA-free plastic dehydrator trays

BPA-free plastic trays in dehydrators offer a lightweight, non-corrosive option for drying mushrooms, ensuring no chemical leaching during the dehydration process. Stainless steel trays provide durability and easy cleaning but may retain heat unevenly, whereas BPA-free plastic trays maintain consistent airflow for optimal mushroom dehydration.

Modular stainless steel mesh trays

Modular stainless steel mesh trays in dehydrators offer superior airflow and even drying for mushrooms compared to plastic trays, enhancing moisture removal and preventing spoilage. Their durability and ease of cleaning make them ideal for repeated use, ensuring consistent dehydration performance and longer equipment lifespan.

Cross-contamination-resistant drying

Stainless steel tray dehydrators offer superior cross-contamination-resistant drying for mushrooms due to their non-porous, easy-to-clean surfaces that prevent residue buildup and bacterial growth, unlike plastic trays that can harbor contaminants in microscopic scratches. The durability and chemical resistance of stainless steel trays ensure safer, more hygienic drying cycles, minimizing the risk of cross-contamination in mushroom dehydration.

Low-residue plastic tray surfaces

Plastic tray dehydrators for mushrooms offer low-residue surfaces that minimize sticking and simplify cleaning, preserving mushroom quality during dehydration. Stainless steel trays, while durable and resistant to corrosion, often retain more residue, requiring more intensive maintenance to prevent contamination.

Thermal-resistant stainless dehydration

Stainless steel tray dehydrators offer superior thermal resistance and durability compared to plastic tray dehydrators, ensuring efficient and consistent moisture removal from mushrooms without risk of melting or warping under high temperatures. Their corrosion-resistant properties also enhance longevity and hygiene, making them ideal for repetitive dehydration processes in mushroom preservation.

Porous mesh airflow optimization

Plastic tray dehydrators often feature a porous mesh design that enhances airflow, promoting even drying and preventing moisture buildup in mushrooms. Stainless steel tray dehydrators provide durable, non-porous surfaces yet typically require perforated inserts to optimize airflow and avoid uneven dehydration.

Non-reactive material mushroom drying

Stainless steel tray dehydrators provide a non-reactive surface that prevents contamination and preserves the natural flavor and nutrients of mushrooms during drying, unlike plastic trays which may release harmful chemicals under heat. Choosing stainless steel ensures safe, efficient dehydration with long-lasting durability and easy cleaning.

Spore retention efficiency

Stainless steel tray dehydrators provide superior spore retention efficiency for mushrooms due to their non-porous surface, which prevents spore absorption and contamination. Plastic tray dehydrators tend to retain spores within their micro-textures, reducing overall spore collection and potentially affecting mushroom quality.

Plastic tray dehydrator vs Stainless steel tray dehydrator for mushrooms. Infographic

cookingdiff.com

cookingdiff.com