Using a rolling pin for dehydrating pet treats allows precise control over dough thickness but can lead to inconsistent results depending on pressure applied. An adjustable thickness roller offers uniform thickness settings, ensuring even dehydration and consistent texture across all treats. Choosing an adjustable roller simplifies the process, producing more reliable and professional-quality dehydrated pet snacks.

Table of Comparison

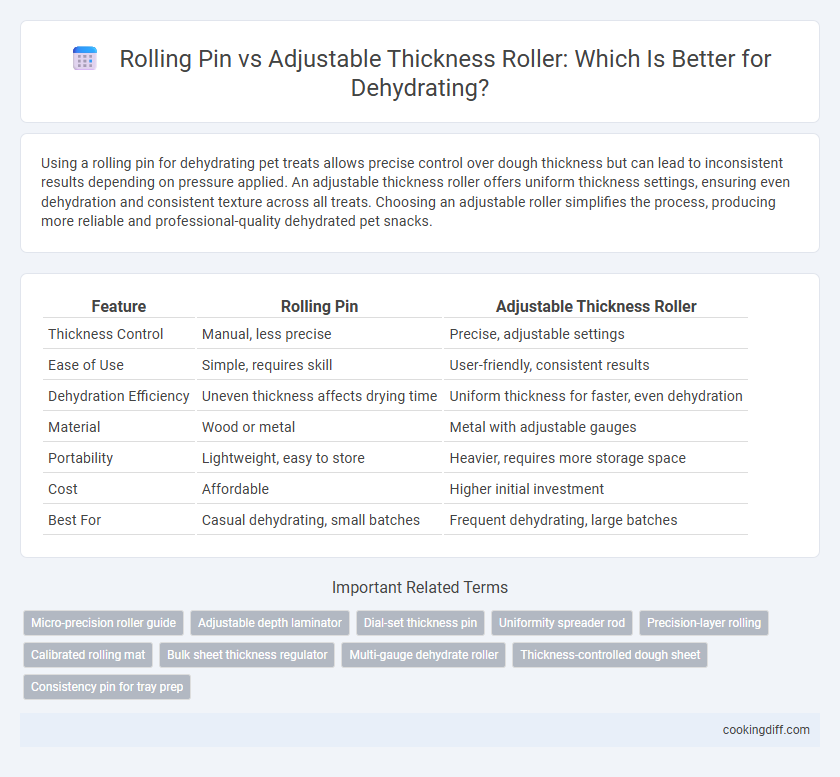

| Feature | Rolling Pin | Adjustable Thickness Roller |

|---|---|---|

| Thickness Control | Manual, less precise | Precise, adjustable settings |

| Ease of Use | Simple, requires skill | User-friendly, consistent results |

| Dehydration Efficiency | Uneven thickness affects drying time | Uniform thickness for faster, even dehydration |

| Material | Wood or metal | Metal with adjustable gauges |

| Portability | Lightweight, easy to store | Heavier, requires more storage space |

| Cost | Affordable | Higher initial investment |

| Best For | Casual dehydrating, small batches | Frequent dehydrating, large batches |

Understanding Rolling Pins in Dehydrating Recipes

Rolling pins are essential tools in dehydrating recipes for evenly flattening dough or fruit slices before drying, ensuring consistent moisture loss and texture. Unlike adjustable thickness rollers, standard rolling pins provide less control over the thickness, which can impact drying times and final product quality. Understanding the optimal thickness for specific dehydrated foods helps achieve uniform dehydration and prevents over-drying or under-drying.

What Is an Adjustable Thickness Roller?

An adjustable thickness roller is a kitchen tool designed to roll out dough or slices to a precise thickness, which is crucial for even dehydrating. Its adjustable settings allow users to customize the thickness for various dehydrating needs, unlike a traditional rolling pin that lacks this control.

This roller enhances consistency in dehydrated products by ensuring uniform thickness, which aids in even drying and prevents under- or over-dehydration. It is especially beneficial when preparing fruits, vegetables, or jerky slices that require specific thickness levels for optimal dehydration. The adjustable thickness roller offers precision and efficiency, making it a valuable tool in the dehydrating process.

Material Differences: Wood, Silicone, and More

Wood rolling pins offer a traditional, sturdy option for dehydrating tasks, providing even pressure and a natural non-stick surface. Silicone adjustable thickness rollers allow precise control over dough thickness, preventing uneven dehydration and enhancing consistency. Other materials like stainless steel combine durability with easy cleaning, making them versatile tools for various dehydrating applications.

Precision and Consistency in Food Thickness

Adjustable thickness rollers provide superior precision and consistency in food thickness compared to traditional rolling pins, which rely heavily on user skill. This consistency is crucial for dehydrating as uniform thickness ensures even drying and preserves food quality.

- Adjustable thickness control - Enables precise setting for uniform slices, reducing the risk of uneven dehydration.

- User-friendly operation - Simplifies achieving consistent thickness without extensive practice or guesswork.

- Improved dehydration results - Consistent slices dry evenly, preventing spoilage and optimizing texture and flavor.

Investing in an adjustable thickness roller enhances dehydrating efficiency by delivering precise, consistent food slices every time.

Impact on Dehydrating Times and Results

Using an adjustable thickness roller allows for consistent and precise dough thickness, which results in more even dehydrating times and uniform drying. A rolling pin, however, may cause uneven thickness, leading to variable dehydration rates and potential over- or under-drying of certain areas.

- Consistent Thickness Control - Adjustable rollers provide uniform thickness that optimizes dehydrating efficiency and results.

- Variable Thickness Impact - Rolling pins create irregular thickness, causing uneven moisture loss and longer drying times.

- Dehydration Quality - Even drying with adjustable rollers enhances texture and shelf life compared to uneven results from rolling pins.

Ease of Use: Rolling Pin vs Adjustable Roller

Which tool offers greater ease of use for dehydrating: a rolling pin or an adjustable thickness roller? A rolling pin requires manual control to achieve uniform thickness, which can be challenging for precise dehydration. The adjustable thickness roller provides consistent, customizable slices, enhancing efficiency and reducing preparation time.

Versatility for Different Food Types

Adjustable thickness rollers offer superior versatility for dehydrating a wide range of food types, allowing precise control over thickness that ensures even drying and consistent texture. Rolling pins require more manual skill and can result in uneven slices, making them less effective for delicate or irregularly shaped items.

Using an adjustable thickness roller streamlines the preparation of fruits, vegetables, and meats by quickly adapting to different thickness settings that optimize drying times. In contrast, rolling pins are better suited for simpler tasks but lack the precision needed for diverse dehydrating applications.

Cleaning and Maintenance Considerations

Adjustable thickness rollers typically have multiple components that require disassembly for thorough cleaning, potentially making maintenance more time-consuming compared to a standard rolling pin. Rolling pins offer a simpler design that generally allows for easier and quicker cleaning, which can reduce the risk of residue buildup during dehydrating preparation.

- Adjustable thickness roller complexity - Requires disassembly of parts to clean all crevices thoroughly.

- Rolling pin simplicity - Smooth, single-piece design allows for quick wiping and less frequent deep cleaning.

- Maintenance impact on hygiene - Proper cleaning of adjustable rollers is crucial to prevent mold growth in dehydrated food prep.

Cost Comparison: Investing in Tools

| Rolling Pin | Low upfront cost, typically under $20 |

| Adjustable Thickness Roller | Higher initial investment, ranging from $40 to $70 |

| Cost Efficiency | Rolling pin is budget-friendly but may require more time and precision, adjustable rollers offer consistent thickness reducing waste and rework |

Related Important Terms

Micro-precision roller guide

The adjustable thickness roller offers enhanced micro-precision roller guides, allowing for consistent and ultra-thin slices crucial in uniform dehydration. Rolling pins lack this precise control, leading to variable thickness that can affect drying times and the quality of dehydrated foods.

Adjustable depth laminator

An adjustable depth laminator provides precise control over dough thickness, enhancing uniform dehydration and consistent drying results for optimal texture. This tool outperforms rolling pins by ensuring even moisture removal and minimizing the risk of uneven dehydration in food preparation.

Dial-set thickness pin

Dial-set thickness pins on rolling pins provide precise control over dough thickness, ensuring uniform dehydration and consistent texture in dried foods. Adjustable thickness rollers offer versatility for various thickness settings but may lack the exact measurement precision of dial-set pins, impacting dehydration efficiency.

Uniformity spreader rod

An adjustable thickness roller provides consistent, uniform spreading of dehydrated food slices by allowing precise control over thickness, ensuring even drying and preventing under- or over-dehydration. In contrast, rolling pins often result in uneven thickness, leading to inconsistent dehydration and reduced product quality.

Precision-layer rolling

An adjustable thickness roller offers superior precision-layer rolling for dehydrating by allowing consistent control over dough or fruit leather thickness, ensuring even dehydration and optimal texture. In contrast, a traditional rolling pin lacks precise thickness settings, which can result in uneven layers and inconsistent drying outcomes.

Calibrated rolling mat

A calibrated rolling mat provides precise thickness control when dehydrating, ensuring uniform moisture removal and consistent drying times. Unlike an adjustable thickness roller, it offers a stable, flat surface that maintains dough shape without uneven pressure variations during rolling.

Bulk sheet thickness regulator

Bulk sheet thickness regulators for dehydrating, such as adjustable thickness rollers, ensure precise control over the uniformity of dehydrated sheets, enhancing drying efficiency and product consistency. Unlike rolling pins, adjustable thickness rollers provide consistent pressure and adjustable gaps, allowing for scalable and repeatable thickness regulation critical in bulk food processing.

Multi-gauge dehydrate roller

Multi-gauge dehydrate rollers offer precise thickness control for evenly dehydrated foods, enhancing texture and drying efficiency compared to traditional rolling pins. Adjustable thickness settings ensure consistent moisture removal, reducing drying time and improving the overall quality of dehydrated products.

Thickness-controlled dough sheet

Rolling pins offer basic control over dough thickness but lack precise measurements, making consistent dehydration results challenging. Adjustable thickness rollers provide accurate, uniform dough sheets by allowing exact thickness settings, optimizing dehydration efficiency and texture consistency.

Rolling pin vs Adjustable thickness roller for dehydrating. Infographic

cookingdiff.com

cookingdiff.com