Using an oven for dehydrating pet food offers a cost-effective and straightforward method but may result in uneven drying and potential nutrient loss due to higher temperatures. Freeze dryers preserve the nutritional value and flavor by removing moisture at low temperatures and under vacuum, although they require a significant initial investment and longer processing times. Choosing between oven and freeze drying depends on balancing budget constraints with the desired quality and preservation of pet food.

Table of Comparison

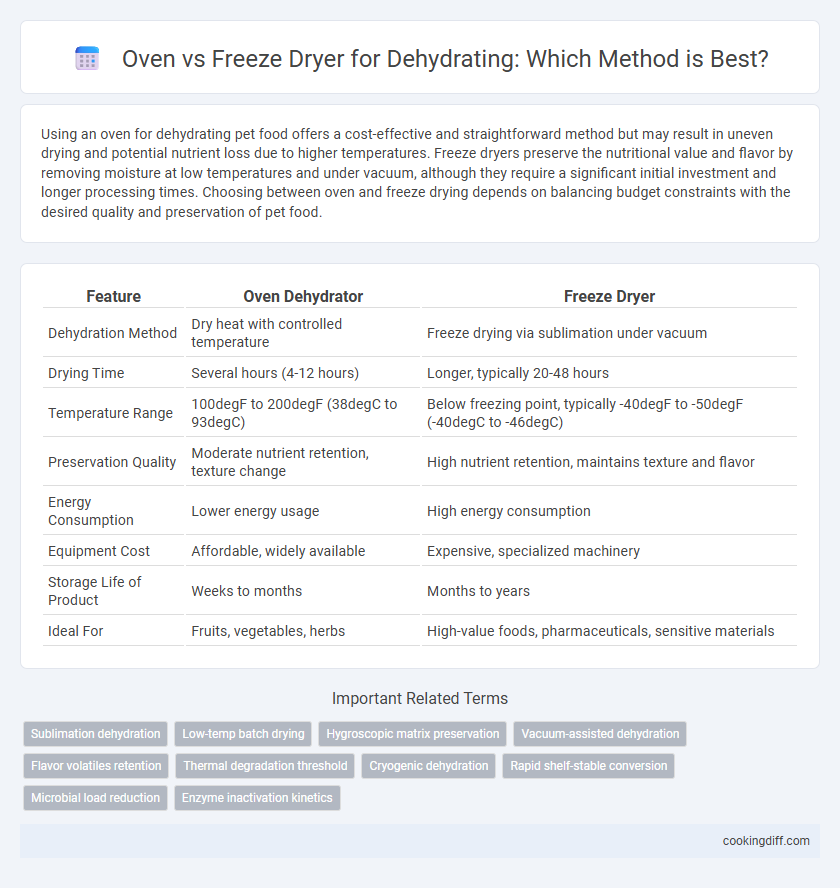

| Feature | Oven Dehydrator | Freeze Dryer |

|---|---|---|

| Dehydration Method | Dry heat with controlled temperature | Freeze drying via sublimation under vacuum |

| Drying Time | Several hours (4-12 hours) | Longer, typically 20-48 hours |

| Temperature Range | 100degF to 200degF (38degC to 93degC) | Below freezing point, typically -40degF to -50degF (-40degC to -46degC) |

| Preservation Quality | Moderate nutrient retention, texture change | High nutrient retention, maintains texture and flavor |

| Energy Consumption | Lower energy usage | High energy consumption |

| Equipment Cost | Affordable, widely available | Expensive, specialized machinery |

| Storage Life of Product | Weeks to months | Months to years |

| Ideal For | Fruits, vegetables, herbs | High-value foods, pharmaceuticals, sensitive materials |

Introduction to Dehydrating: Oven vs Freeze Dryer

Dehydrating food preserves it by removing moisture, which inhibits bacterial growth and extends shelf life. Two popular methods for dehydrating are using an oven or a freeze dryer, each with distinct advantages and applications.

Oven dehydrating is accessible and cost-effective, utilizing low heat to slowly evaporate water from food. Freeze drying, however, involves freezing the food and then reducing pressure to remove moisture via sublimation, preserving nutrients and flavor more effectively. This method offers superior quality but requires specialized equipment and higher upfront investment.

How Ovens Dehydrate Food

| Method | Description |

|---|---|

| Oven Dehydration | Ovens remove moisture by circulating hot air around food, typically at temperatures between 120degF and 200degF (49degC-93degC), causing water to evaporate from the food's surface. |

| Moisture Removal Process | Heat causes water molecules to vaporize, and ventilation within the oven helps carry away the moisture, effectively reducing water content and preserving the food. |

| Optimal Usage | Oven dehydration is best for fruits, vegetables, and meats when controlled temperature and airflow reduce drying time while minimizing nutrient loss. |

How Freeze Dryers Work for Dehydration

Freeze dryers remove moisture through a process called sublimation, where frozen water in the food transitions directly from solid ice to vapor under low pressure. This method preserves the food's cellular structure, nutrients, and flavor more effectively than traditional dehydration methods.

The food is first frozen, then placed in a vacuum chamber to lower the pressure, causing the ice to vaporize without passing through the liquid phase. This results in lightweight, shelf-stable products that retain their original shape and nutritional value for extended storage periods.

Efficiency: Oven vs Freeze Dryer

Oven dehydrators typically consume more energy and require longer drying times, averaging 6 to 12 hours depending on the food type and thickness. Freeze dryers, while using advanced vacuum and freezing technology, operate more efficiently by preserving nutritional content with drying times ranging from 20 to 48 hours but with higher energy demands per cycle.

Freeze drying achieves better moisture removal efficiency, reducing residual water content to below 1%, which significantly extends shelf life compared to oven drying that leaves 5-20% moisture. Despite higher initial costs, freeze dryers offer superior energy efficiency in large-scale or high-value food preservation where product quality and long-term stability are critical.

Nutrient Retention Comparison

Freeze drying preserves a higher percentage of vitamins and antioxidants compared to oven drying due to its low-temperature process. Oven drying often leads to greater nutrient degradation because of exposure to heat and air.

- Freeze dryer retains up to 97% of nutrients - Maintains vitamin C and bioactive compounds by sublimating water under low heat.

- Oven drying nutrient loss ranges from 20% to 50% - Prolonged heat exposure causes oxidation and nutrient breakdown.

- Freeze drying ensures superior antioxidant preservation - Protects phenolic compounds better than conventional oven methods.

Texture and Flavor Results

Oven dehydration typically results in a chewier texture and a more concentrated, caramelized flavor due to the application of consistent dry heat. Freeze drying preserves the original texture much better, maintaining a light, porous, and brittle consistency while retaining the food's natural flavors more accurately. Foods dehydrated in a freeze dryer often rehydrate more effectively, enhancing both texture and flavor when compared to oven-dried products.

Energy Consumption and Cost Analysis

Which method is more energy-efficient and cost-effective for dehydrating, oven or freeze dryer? Oven dehydrators typically consume less energy, averaging around 1.5 kWh per use, making them more affordable for small-scale dehydration. Freeze dryers, while efficient in preserving food quality, operate at higher energy levels between 3 to 7 kWh per cycle, leading to significantly increased operational costs.

Storage Life of Dehydrated Foods

Freeze drying preserves dehydrated foods significantly longer than oven drying, often extending storage life from months to several years due to superior moisture removal. Oven drying typically leaves higher residual moisture, which can reduce shelf life and increase the risk of spoilage. Foods processed with freeze dryers maintain better texture, flavor, and nutrients, enhancing long-term preservation compared to traditional oven dehydration.

Suitable Foods for Oven and Freeze Dryer Dehydration

Ovens are suitable for dehydrating fruits, vegetables, and herbs that can withstand moderate heat without losing essential nutrients, while freeze dryers excel at preserving delicate foods like berries, meats, and dairy with minimal nutrient degradation and texture retention.

- Oven dehydration - ideal for sturdy foods such as apples, tomatoes, and kale that tolerate consistent heat.

- Freeze drying - best for high-moisture, perishable items like strawberries, beef jerky, and cheese to preserve flavor and nutrients.

- Moisture content consideration - low-moisture foods dehydrate efficiently in ovens, whereas high-moisture or heat-sensitive foods benefit from freeze drying.

Choosing the proper dehydration method ensures maximum preservation of nutritional value and texture depending on food type.

Related Important Terms

Sublimation dehydration

Freeze dryers utilize sublimation dehydration by converting ice directly into vapor under low pressure, preserving nutritional content and cellular structure with minimal heat damage. In contrast, ovens apply heat that can degrade sensitive nutrients and alter texture, making freeze drying superior for maintaining food quality during dehydration.

Low-temp batch drying

Oven drying typically operates at temperatures between 50-70degC, which can lead to nutrient degradation and uneven drying during low-temp batch drying processes. Freeze drying preserves nutritional content and texture by sublimating ice directly from frozen samples under low temperature and vacuum conditions, making it superior for sensitive foods despite higher initial costs.

Hygroscopic matrix preservation

Oven drying can cause significant loss of volatile compounds and damage the hygroscopic matrix, leading to reduced preservation of bioactive properties. Freeze drying effectively preserves the hygroscopic matrix by sublimating moisture under low temperature and pressure, maintaining structural integrity and enhancing long-term stability of dehydrated products.

Vacuum-assisted dehydration

Vacuum-assisted dehydration enhances both oven and freeze drying by reducing boiling points, which preserves heat-sensitive nutrients and colors more effectively. Freeze dryers combine vacuum pressure with sublimation for superior moisture removal and texture retention, while vacuum oven dehydrators use controlled heat under vacuum to accelerate drying with less nutrient degradation than conventional ovens.

Flavor volatiles retention

Freeze drying preserves flavor volatiles more effectively than oven drying by sublimating water at low temperatures, minimizing heat-induced loss or alteration of aromatic compounds. Oven drying, which uses elevated temperatures, accelerates moisture removal but leads to significant degradation of delicate flavor volatiles, resulting in reduced aroma intensity.

Thermal degradation threshold

Oven dehydrators expose food to temperatures typically between 50degC and 70degC, often surpassing the thermal degradation threshold of sensitive nutrients like vitamin C and enzymes, leading to nutrient loss and altered texture. Freeze dryers operate below freezing and under vacuum conditions, preserving nutritional quality by avoiding thermal degradation and maintaining cellular structure during the dehydration process.

Cryogenic dehydration

Cryogenic dehydration using freeze dryers preserves cellular structure and nutrient content by sublimating ice directly from frozen material under low temperature and vacuum conditions, unlike ovens that rely on heat to evaporate water, often causing nutrient degradation and texture loss. Freeze drying is especially advantageous for heat-sensitive foods and pharmaceuticals, maintaining bioactive compounds and extending shelf life with minimal distortion.

Rapid shelf-stable conversion

Oven dehydrators use consistent heat to rapidly remove moisture, offering a cost-effective and straightforward method for producing shelf-stable foods but can degrade heat-sensitive nutrients. Freeze dryers preserve nutritional content and flavor by sublimating ice under low temperature and vacuum, enabling rapid conversion to lightweight, shelf-stable products with extended shelf life.

Microbial load reduction

Oven dehydrating typically reduces microbial load by applying consistent heat, effectively lowering moisture content to inhibit bacterial growth, though it may not eliminate all pathogens. Freeze drying achieves more significant microbial reduction by rapidly freezing and then sublimating moisture under vacuum, preserving product quality while destroying a broader spectrum of microorganisms.

Oven vs Freeze dryer for dehydrating. Infographic

cookingdiff.com

cookingdiff.com