Microwave drying offers rapid moisture removal ideal for quick snack preparation, preserving flavor and texture effectively. Vacuum dehydrators operate at lower temperatures, enhancing nutrient retention and preventing oxidation for longer shelf life. Choosing between these methods depends on desired processing speed and product quality for snack dehydration.

Table of Comparison

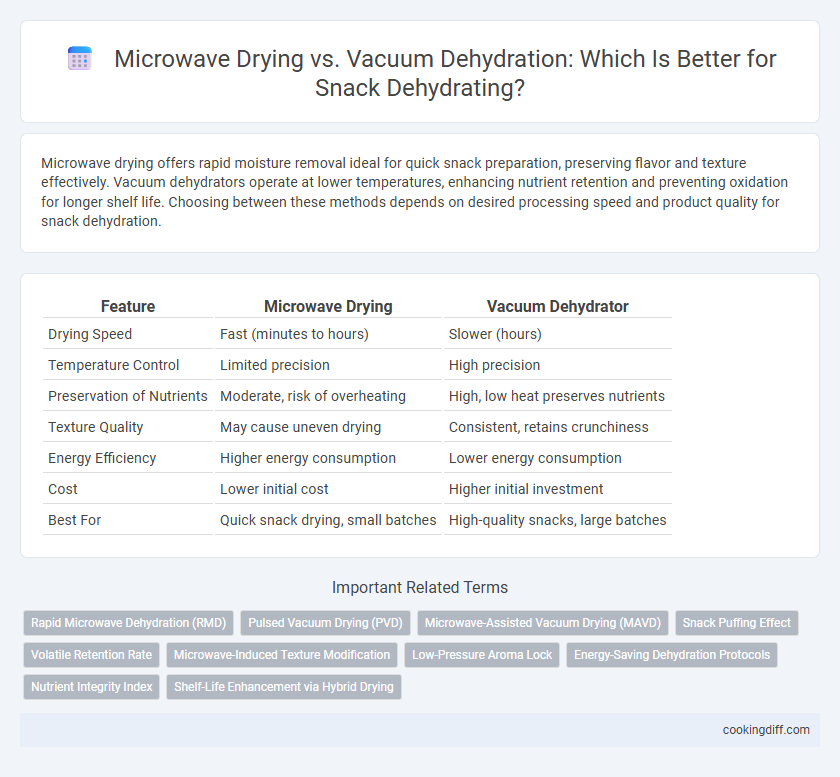

| Feature | Microwave Drying | Vacuum Dehydrator |

|---|---|---|

| Drying Speed | Fast (minutes to hours) | Slower (hours) |

| Temperature Control | Limited precision | High precision |

| Preservation of Nutrients | Moderate, risk of overheating | High, low heat preserves nutrients |

| Texture Quality | May cause uneven drying | Consistent, retains crunchiness |

| Energy Efficiency | Higher energy consumption | Lower energy consumption |

| Cost | Lower initial cost | Higher initial investment |

| Best For | Quick snack drying, small batches | High-quality snacks, large batches |

Introduction to Snack Dehydration Methods

| Microwave drying rapidly removes moisture from snacks through electromagnetic radiation, preserving nutrients and reducing processing time significantly. |

| Vacuum dehydrators extract water under low pressure and temperature, maintaining texture and flavor integrity while extending shelf life. |

| Both methods optimize snack dehydration but prioritize speed in microwave drying and quality retention in vacuum dehydration. |

How Microwave Drying Works for Snacks

Microwave drying uses electromagnetic waves to rapidly heat and evaporate moisture from snacks, reducing drying time compared to conventional methods. This technique preserves texture and flavor by quickly removing water content without excessive heat exposure.

- Rapid Moisture Removal - Microwaves penetrate snack material, causing water molecules to vibrate and evaporate swiftly, accelerating the drying process.

- Energy Efficiency - Microwave drying consumes less energy by targeting moisture directly, making it more efficient than many traditional dehydrating methods.

- Retention of Nutrients and Flavor - By minimizing exposure to high temperatures for prolonged periods, microwave drying helps preserve vitamins and natural flavors in snacks.

Understanding Vacuum Dehydrator Technology

Vacuum dehydrator technology removes moisture from snacks at low temperatures by creating a low-pressure environment, preserving flavor and nutritional content more effectively than microwave drying. Unlike microwave drying, which uses high heat that can degrade sensitive nutrients and alter texture, vacuum dehydration maintains the quality and shelf life of dried products. This method is particularly advantageous for delicate snacks such as fruits and herbs, ensuring better preservation of color, aroma, and taste.

Speed and Efficiency: Microwave vs Vacuum Dehydration

Microwave drying significantly reduces dehydration time by using rapid electromagnetic waves that excite water molecules, making it ideal for quick snack preparation. This method efficiently preserves nutrients and flavor but may cause uneven drying if not properly controlled.

Vacuum dehydrators operate by lowering pressure to reduce the boiling point of water, enabling moisture removal at lower temperatures, which enhances flavor retention and texture quality. Though slower than microwave drying, vacuum dehydration offers superior uniformity and extended shelf life for snacks.

Nutrient Retention in Microwave-Dried vs Vacuum-Dehydrated Snacks

Microwave drying preserves nutrients in snacks by reducing exposure time to heat compared to traditional methods, leading to higher retention of vitamins such as C and B-complex. Vacuum dehydrators operate at lower temperatures and reduced pressure, which slows oxidation and better preserves sensitive antioxidants and enzymes.

Microwave-dried snacks typically retain more water-soluble vitamins due to rapid processing, but vacuum dehydration excels in conserving heat-sensitive phytochemicals and flavor compounds. Studies demonstrate vacuum dehydration results in longer shelf life and improved texture due to minimal nutrient degradation. Both methods offer distinct advantages, with vacuum dehydration favored for delicate fruits and microwave drying preferred for quick processing of vegetables and herbs.

Flavor and Texture: Comparing Snack Quality

Microwave drying preserves more of the snack's original flavor by rapidly removing moisture, while vacuum dehydrators enhance texture by drying at lower temperatures to maintain crispness. Vacuum dehydration generally results in a more uniform texture, preventing tough spots common in microwave-dried snacks.

- Flavor retention in microwave drying - Rapid moisture removal minimizes flavor loss compared to slower methods.

- Texture quality in vacuum dehydrators - Low-temperature drying preserves a consistent, crispy texture.

- Comparison of snack quality - Microwave drying emphasizes flavor preservation; vacuum dehydration optimizes texture integrity.

Energy Consumption and Cost Considerations

Microwave drying typically uses less energy per batch compared to vacuum dehydrators, making it more efficient for small-scale snack production. Vacuum dehydrators consume more power due to their longer processing times and vacuum generation but offer superior product quality and shelf life.

- Microwave drying energy efficiency - Microwave dehydrators use electromagnetic waves that penetrate snacks directly, reducing drying time and energy use.

- Vacuum dehydrator power demand - Vacuum systems require continuous operation of vacuum pumps and heating elements, increasing overall energy consumption.

- Cost implications - Initial costs for microwave dryers are generally lower, but vacuum dehydrators may save money over time via reduced spoilage and higher product value.

Selecting between microwave drying and vacuum dehydration depends on balancing upfront investment with long-term energy and quality considerations.

Best Snack Types for Each Dehydration Method

Microwave drying is ideal for fruits like apples and berries that dry quickly and retain vibrant color and flavor with minimal nutrient loss. This method is also suitable for thin slices of vegetables, ensuring a crispy texture perfect for snacks like kale chips or carrot crisps.

Vacuum dehydrators excel in preserving delicate herbs, nuts, and meat jerky by drying at low temperatures, which retains essential oils and nutrients. This slow drying method is best for dense snacks requiring extended drying, such as beef jerky and nut mixes, maintaining texture and flavor integrity.

Safety and Ease of Use in Home Kitchens

Microwave drying offers rapid dehydration of snacks but requires careful monitoring to prevent overheating and uneven drying, which can pose safety risks in home kitchens. Vacuum dehydrators operate at lower temperatures, reducing the chance of nutrient loss or burning, and feature built-in safety mechanisms that make them user-friendly for consistent results. Ease of use is enhanced in vacuum dehydrators with preset programs and clear controls, while microwave drying demands more manual attention and experience to achieve optimal snack quality safely.

Related Important Terms

Rapid Microwave Dehydration (RMD)

Rapid Microwave Dehydration (RMD) significantly accelerates moisture removal in snack production compared to traditional vacuum dehydrators by combining microwave energy and controlled vacuum pressure, resulting in faster drying times and enhanced preservation of flavor and nutrients. RMD's efficient heat transfer mechanism reduces oxidative damage and microbial growth, producing high-quality dehydrated snacks with improved texture and shelf life.

Pulsed Vacuum Drying (PVD)

Pulsed Vacuum Drying (PVD) enhances microwave drying efficiency by alternating pressure levels to accelerate moisture removal while preserving nutritional quality and texture in snacks. Compared to vacuum dehydrators, PVD significantly reduces drying time and energy consumption, making it a superior method for producing high-quality, shelf-stable snack products.

Microwave-Assisted Vacuum Drying (MAVD)

Microwave-Assisted Vacuum Drying (MAVD) combines microwave energy and vacuum pressure to accelerate water removal while preserving the nutritional quality and texture of snacks. MAVD offers faster drying times and enhanced energy efficiency compared to conventional microwave drying and vacuum dehydrators, making it ideal for heat-sensitive food products.

Snack Puffing Effect

Microwave drying rapidly heats snack ingredients, causing expansion and creating a distinct puffing effect ideal for light, crispy textures, while vacuum dehydrators remove moisture at low pressure and temperature, resulting in denser, less expanded snacks with minimal puffing. The puffing effect from microwave drying enhances mouthfeel and visual appeal, making it preferable for producing airy snack products compared to the more compact results of vacuum dehydration.

Volatile Retention Rate

Microwave drying maintains a higher volatile retention rate compared to vacuum dehydrators, preserving more natural flavors and aromas in snacks due to its rapid heating process that minimizes volatile compound loss. Vacuum dehydrators, while effective in moisture removal, often result in lower volatile retention because prolonged low-pressure drying can lead to the evaporation of essential oils and flavor compounds.

Microwave-Induced Texture Modification

Microwave drying accelerates moisture removal by generating volumetric heat, which induces unique texture modifications such as puffiness and crispness in snacks, enhancing their sensory appeal. Vacuum dehydrators operate at low pressures to remove water gently, preserving structural integrity but often resulting in denser textures compared to the porous, crunchy textures created by microwave-induced rapid vaporization.

Low-Pressure Aroma Lock

Microwave drying offers rapid moisture removal but can compromise flavor due to uneven heat distribution, whereas vacuum dehydrators operate under low-pressure conditions that enhance Low-Pressure Aroma Lock technology, preserving the natural taste and aroma of snacks. Vacuum dehydration maintains product quality by minimizing oxidation and heat damage, making it ideal for flavor-sensitive foods.

Energy-Saving Dehydration Protocols

Microwave drying consumes significantly less energy by rapidly removing moisture through dielectric heating, whereas vacuum dehydrators operate at lower temperatures and pressures to preserve nutrient quality but often require longer drying times, resulting in higher overall energy use. Energy-saving dehydration protocols favor microwave drying for its speed and efficiency, though vacuum dehydration remains preferable for heat-sensitive snacks where energy cost is balanced against product quality.

Nutrient Integrity Index

Microwave drying preserves nutrients rapidly due to shorter exposure to heat, resulting in a higher Nutrient Integrity Index compared to conventional vacuum dehydrators which operate at lower temperatures but longer durations, potentially causing more nutrient degradation. Vacuum dehydrators excel in moisture removal efficiency but may compromise sensitive vitamins and antioxidants, making microwave drying preferable for nutrient retention in snacks.

Microwave drying vs Vacuum dehydrator for snacks Infographic

cookingdiff.com

cookingdiff.com