A manual chopper offers precise control over uniform cutting, which ensures even dehydration by producing consistently sized pieces, ideal for pet treats. Spiralizers create long, thin strands that dry quickly but may result in uneven moisture retention depending on the thickness and type of vegetable used. Choosing between the two depends on the desired texture and drying time for the dehydrated pet food.

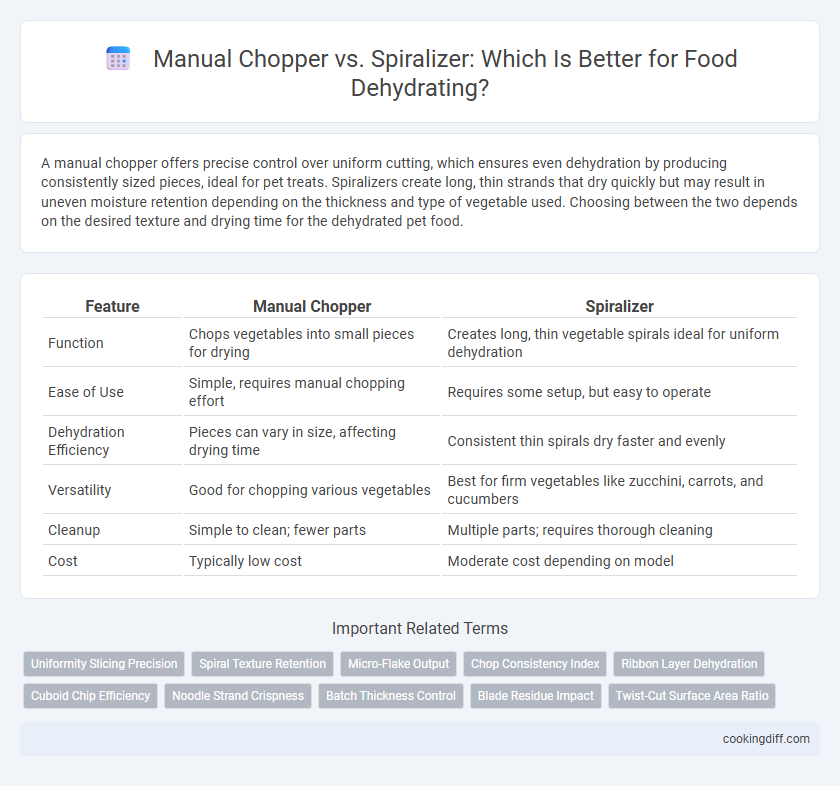

Table of Comparison

| Feature | Manual Chopper | Spiralizer |

|---|---|---|

| Function | Chops vegetables into small pieces for drying | Creates long, thin vegetable spirals ideal for uniform dehydration |

| Ease of Use | Simple, requires manual chopping effort | Requires some setup, but easy to operate |

| Dehydration Efficiency | Pieces can vary in size, affecting drying time | Consistent thin spirals dry faster and evenly |

| Versatility | Good for chopping various vegetables | Best for firm vegetables like zucchini, carrots, and cucumbers |

| Cleanup | Simple to clean; fewer parts | Multiple parts; requires thorough cleaning |

| Cost | Typically low cost | Moderate cost depending on model |

Introduction to Dehydrating: Manual Chopper vs Spiralizer

Dehydrating requires precise slicing to ensure even drying and preserve nutrients. Choosing between a manual chopper and a spiralizer affects texture and drying efficiency.

- Manual Chopper - Offers uniform, thick slices ideal for slow, consistent dehydration.

- Spiralizer - Produces thin, noodle-like strips that dry quickly and are perfect for creative presentations.

- Dehydration Efficiency - Proper slicing with either tool reduces drying time and maintains food quality.

Key Differences Between Manual Choppers and Spiralizers

| Feature | Manual Chopper | Spiralizer |

|---|---|---|

| Cutting Style | Produces irregular, chopped pieces ideal for uniform drying | Creates long, continuous spiral cuts, enhancing surface area for faster dehydration |

| Efficiency | Requires more physical effort and time for large quantities | Allows quicker processing of vegetables, especially zucchini and carrots |

| Use Case | Best for dicing fruits and vegetables into consistent chunks for balanced drying | Perfect for creating spiraled vegetables suitable for recipe presentation and rapid dehydration |

Efficiency in Food Preparation for Dehydrating

Manual choppers offer speed by quickly chopping large quantities of food, ideal for efficiently preparing ingredients for dehydrating. Spiralizers create uniform, thin spiral cuts that ensure consistent dehydration and enhanced texture, particularly for vegetables. Choosing between these tools depends on whether rapid preparation or uniform slicing is prioritized for optimal dehydration results.

Consistency of Slices: Impact on Dehydration Quality

How does the consistency of slices from a manual chopper compare to a spiralizer for dehydrating? Manual choppers often produce uneven slices, resulting in inconsistent dehydration and varied texture in dried foods. Spiralizers create uniform, continuous strips, promoting even drying and improved preservation quality.

Speed and Ease of Use for Large Batches

Manual choppers offer faster processing speeds for large batches due to their straightforward chopping mechanism, enabling quick preparation of uniform pieces ideal for even dehydration. Spiralizers require more effort and time per batch, especially with dense vegetables, making them less efficient for high-volume dehydrating tasks. The ease of use in manual choppers reduces fatigue and speeds up workflow, crucial when handling large quantities for dehydration projects.

Versatility for Different Fruits and Vegetables

Manual choppers provide versatility by accommodating a wide range of fruits and vegetables in various sizes and textures, making them suitable for preparing ingredients for dehydrating. They allow for customized cuts, from chunks to slices, enhancing the drying process for items like apples, carrots, and potatoes.

Spiralizers excel in creating uniform, spiral cuts ideal for vegetables such as zucchini and cucumbers, which promotes even dehydration and attractive presentation. Their design limits use mostly to long, firm vegetables, reducing flexibility when processing softer or irregularly shaped produce.

Cleaning and Maintenance Considerations

Manual choppers typically have fewer parts and simpler mechanisms, making them easier to clean thoroughly after dehydrating vegetables. Spiralizers often feature multiple blades and intricate components that require careful disassembly to ensure all food residue is removed effectively.

Maintaining a manual chopper usually involves quick rinsing and occasional blade sharpening, which demands minimal time investment. Spiralizers need regular blade maintenance and thorough cleaning to prevent buildup in hard-to-reach areas, ensuring optimal performance and hygiene. Choosing between the two depends on your willingness to allocate time for detailed cleaning and upkeep.

Storage and Space Requirements

Manual choppers are compact and easy to store, making them ideal for kitchens with limited counter space. Spiralizers, while offering more decorative slicing options, tend to be bulkier and require more storage space due to their larger frames.

- Manual choppers take up minimal space - Their small size allows for easy storage in drawers or cabinets.

- Spiralizers have larger footprints - Designed with extended arms and multiple attachments, they occupy more countertop or shelf space.

- Choosing between the two depends on kitchen storage capacity - Users must balance space availability with the desired functionality for dehydrating food.

Cost Comparison: Manual Chopper vs Spiralizer

Manual choppers generally have a lower upfront cost, often priced between $10 and $30, making them budget-friendly for dehydrating tasks. Spiralizers, especially high-quality models, range from $20 to $50, reflecting their multifunctional design.

While manual choppers are economical, spiralizers provide value by producing uniform vegetable spirals, which can enhance drying efficiency. The choice depends on whether initial expense or dehydration effectiveness is prioritized.

Related Important Terms

Uniformity Slicing Precision

Manual choppers offer less uniform slicing precision compared to spiralizers, which create consistent, evenly cut spirals ideal for even dehydration. Spiralizers ensure uniform texture and drying times, reducing the risk of uneven moisture retention and spoilage during the dehydration process.

Spiral Texture Retention

A spiralizer preserves the texture of vegetables during dehydration by creating uniform, thin strands that dry evenly and retain structural integrity. This method enhances moisture evaporation while maintaining the visual appeal and crispness compared to the uneven cuts produced by a manual chopper.

Micro-Flake Output

Manual choppers produce larger, unevenly sized pieces that may lead to inconsistent dehydration and less efficient moisture removal. Spiralizers create uniform, thin spirals or ribbons ideal for micro-flake output, promoting faster drying and enhanced texture in dehydrated foods.

Chop Consistency Index

Manual choppers produce unevenly sized pieces, resulting in a lower Chop Consistency Index and inconsistent dehydration rates, whereas spiralizers create uniform, consistent cuts that enhance drying efficiency. High Chop Consistency Index from spiralizers ensures even moisture removal, reducing drying time and preserving texture during dehydration.

Ribbon Layer Dehydration

Manual choppers create uneven ribbon layers that can result in inconsistent dehydration times and texture, while spiralizers produce uniform, thin ribbons that enhance airflow and accelerate even drying. Uniform ribbon layers from spiralizers optimize moisture removal efficiency and preserve nutrient quality during dehydrating processes.

Cuboid Chip Efficiency

Manual choppers produce uniform cuboid chips that dehydrate evenly and faster due to consistent thickness and shape, improving drying efficiency. Spiralizers create long, thin strands that may dry unevenly and take longer, reducing overall cuboid chip efficiency for dehydration.

Noodle Strand Crispness

Manual choppers produce thicker, uneven noodle strands that often require longer dehydrating times and may result in less consistent crispness. Spiralizers create uniform, thin strands that dehydrate more evenly and quickly, enhancing noodle strand crispness and texture.

Batch Thickness Control

Manual choppers allow for adjustable batch thickness by controlling the size of each chop, offering variable dehydrating times and uniform drying. Spiralizers produce consistent, thin spirals that ensure faster dehydration and even moisture removal due to uniform thickness.

Blade Residue Impact

Manual choppers often leave irregular blade residue that can trap moisture, slowing the dehydration process and affecting texture consistency. Spiralizers produce uniform, thin slices with minimal blade residue, promoting faster and more even dehydration for optimal preservation.

Manual chopper vs Spiralizer for dehydrating. Infographic

cookingdiff.com

cookingdiff.com