Oven drying uses heat to evaporate moisture quickly but can cause nutrient loss and alter texture in sensitive foods. Freeze drying preserves nutritional content and texture by freezing the product and removing moisture under low pressure, though it requires specialized equipment and longer processing time. Choosing between oven drying and freeze drying depends on the desired quality, cost, and application of the dehydrated product.

Table of Comparison

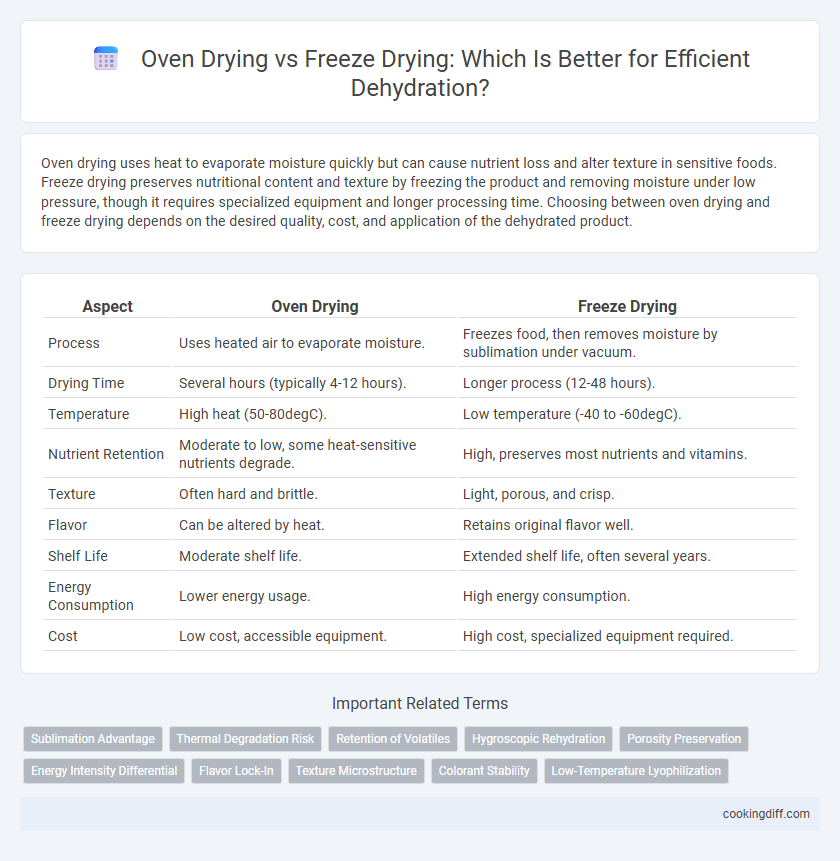

| Aspect | Oven Drying | Freeze Drying |

|---|---|---|

| Process | Uses heated air to evaporate moisture. | Freezes food, then removes moisture by sublimation under vacuum. |

| Drying Time | Several hours (typically 4-12 hours). | Longer process (12-48 hours). |

| Temperature | High heat (50-80degC). | Low temperature (-40 to -60degC). |

| Nutrient Retention | Moderate to low, some heat-sensitive nutrients degrade. | High, preserves most nutrients and vitamins. |

| Texture | Often hard and brittle. | Light, porous, and crisp. |

| Flavor | Can be altered by heat. | Retains original flavor well. |

| Shelf Life | Moderate shelf life. | Extended shelf life, often several years. |

| Energy Consumption | Lower energy usage. | High energy consumption. |

| Cost | Low cost, accessible equipment. | High cost, specialized equipment required. |

Introduction to Oven Drying and Freeze Drying

Oven drying involves using controlled heat to remove moisture from food, typically at temperatures between 50-70degC, which helps preserve texture and flavor while reducing drying time. Freeze drying, or lyophilization, freezes the food and then reduces surrounding pressure to allow the frozen water to sublimate directly from solid to gas, retaining nutritional content and structure more effectively. Both methods serve to dehydrate by removing moisture but differ significantly in processing time, energy consumption, and impact on food quality.

How Oven Drying Works

Oven drying removes moisture from food by circulating hot air at controlled temperatures, typically between 120degF and 200degF, which evaporates water content. This method is cost-effective and faster than freeze drying but can affect the texture and nutritional value of the food.

- Heat Application - Hot air is used to evaporate moisture evenly from the food surface.

- Temperature Control - Precise temperature settings prevent cooking or burning while drying.

- Moisture Removal - Continuous air circulation carries away released moisture for efficient drying.

How Freeze Drying Works

Freeze drying involves freezing the material and then reducing the surrounding pressure to allow the frozen water in the material to sublimate directly from solid to gas. This process preserves the structure, flavor, and nutritional value better than oven drying, which uses heat to evaporate moisture.

- Freezing Stage - The product is rapidly frozen to convert water content into ice crystals.

- Sublimation Phase - Under low pressure, ice turns directly into vapor, bypassing the liquid phase.

- Secondary Drying - Residual moisture is removed by gradually increasing temperature while maintaining low pressure.

Freeze drying produces lightweight and shelf-stable products with minimal nutrient loss compared to oven drying.

Key Differences Between Oven Drying and Freeze Drying

Oven drying uses heat to remove moisture from food, which can degrade nutrients and affect texture, while freeze drying removes moisture through sublimation at low temperatures, preserving nutritional value and original structure. Freeze drying is more energy-intensive and costly compared to the relatively simple and affordable oven drying process.

Freeze drying results in lightweight, shelf-stable products with better rehydration properties, making it ideal for long-term storage and sensitive ingredients. Oven drying is faster but may cause shrinkage, uneven drying, and loss of volatile compounds important for flavor and aroma.

Nutritional Impact: Oven Drying vs Freeze Drying

Oven drying causes nutrient loss due to heat exposure, especially reducing sensitive vitamins like vitamin C and some B vitamins. Freeze drying preserves most nutrients by sublimating water at low temperatures, maintaining the food's original nutritional profile more effectively.

Though oven drying is faster and more cost-effective, it compromises nutrient retention compared to freeze drying. Freeze drying retains up to 90-95% of nutrients, including antioxidants and enzymes, making it superior for preserving nutritional quality. This makes freeze drying ideal for nutrient-sensitive foods like fruits and herbs where maintaining vitamins and flavor is crucial.

Texture and Flavor Changes in Dehydrated Foods

Oven drying often results in a tougher, chewier texture due to higher heat exposure, which can also cause slight caramelization altering the flavor profile. Freeze drying maintains the original texture by sublimating moisture at low temperatures, preserving the food's natural flavor more effectively.

- Texture Impact - Oven drying can lead to a dense, leathery texture while freeze drying yields a light, porous, and crisp product.

- Flavor Retention - Freeze drying better preserves volatile compounds, maintaining the food's fresh taste compared to the slightly cooked flavor from oven drying.

- Nutrient Stability - Freeze drying retains more vitamins and antioxidants due to lower processing temperatures in comparison to oven drying.

Shelf Life Comparison: Oven vs Freeze Dried Foods

Freeze drying significantly extends the shelf life of foods, often preserving them for 20 to 30 years due to its low temperature and vacuum process that removes moisture without damaging nutrients. Oven drying typically results in a shorter shelf life, averaging 6 months to 1 year, since the higher temperatures can degrade food quality and increase oxidation risk.

Freeze dried foods maintain better flavor, texture, and nutritional value over time, which contributes to their longer shelf stability compared to oven dried products. The reduced moisture content in freeze dried foods inhibits microbial growth more effectively than the residual moisture left in oven dried items.

Equipment and Cost Considerations

Oven drying requires basic kitchen equipment like a conventional oven, making it more accessible and cost-effective for home use. Freeze drying demands specialized, expensive machinery that uses vacuum and low temperatures to preserve food quality but comes with high initial investment and maintenance costs. While oven drying is budget-friendly and simpler, freeze drying ensures superior preservation but at a significantly higher equipment and operational expense.

Best Foods for Oven Drying and Freeze Drying

Which foods are best suited for oven drying versus freeze drying? Oven drying works well for fruits like apples and bananas, as well as herbs and jerky due to its consistent heat application. Freeze drying is ideal for delicate foods such as berries, coffee, and ready-to-eat meals because it preserves texture and nutrients by removing moisture under low temperature and pressure.

Related Important Terms

Sublimation Advantage

Freeze drying utilizes sublimation to remove moisture directly from ice to vapor, preserving food texture, flavor, and nutrients better than oven drying, which relies on evaporation and high heat that can degrade quality. This sublimation advantage in freeze drying results in superior shelf stability and faster rehydration compared to conventional oven drying methods.

Thermal Degradation Risk

Oven drying exposes materials to higher temperatures, increasing the risk of thermal degradation and nutrient loss, whereas freeze drying uses low temperatures under vacuum, effectively preserving heat-sensitive compounds and minimizing structural damage. Freeze drying's ability to maintain product integrity makes it ideal for fragile biological samples and pharmaceuticals sensitive to thermal stress.

Retention of Volatiles

Oven drying often results in significant loss of volatile compounds due to exposure to high temperatures and prolonged drying times, which can alter flavor and aroma profiles. Freeze drying preserves volatiles more effectively by sublimating moisture under low temperatures and vacuum, maintaining the integrity of delicate essential oils and aromatic compounds.

Hygroscopic Rehydration

Oven drying typically results in higher hygroscopic rehydration rates due to the partial collapse of cellular structure, allowing greater water absorption upon rehydration, whereas freeze drying preserves the porous microstructure, minimizing hygroscopic rehydration but enhancing rapid water uptake and texture retention. The choice between oven and freeze drying techniques significantly impacts the product's hygroscopic behavior, influencing shelf life and rehydration quality in dehydrated foods.

Porosity Preservation

Freeze drying preserves porosity by sublimating ice directly from frozen samples, maintaining the material's cellular structure and preventing collapse. Oven drying removes moisture through heat, often causing shrinkage and reduced porosity due to cell wall collapse and structural damage.

Energy Intensity Differential

Oven drying consumes significantly more energy than freeze drying due to continuous high-temperature operation, often reaching up to 5 kWh per kilogram of moisture removed compared to freeze drying's approximate 2-3 kWh per kilogram. Freeze drying's vacuum and sublimation process, despite longer cycle times, achieves superior energy efficiency by minimizing heat loss and preserving product integrity.

Flavor Lock-In

Oven drying tends to degrade volatile flavor compounds due to prolonged heat exposure, leading to less intense taste retention, while freeze drying preserves flavor by sublimating moisture under low temperatures, effectively locking in aroma and nutrient profiles. Freeze drying maintains superior flavor integrity and texture compared to oven drying, making it ideal for high-quality dehydrated products.

Texture Microstructure

Oven drying causes cell wall collapse and shrinkage, leading to a dense, brittle texture due to heat-induced moisture loss, whereas freeze drying preserves the cellular structure by sublimation, resulting in a porous, lightweight texture that closely retains the original microstructure. The microstructural differences directly impact rehydration capacity and sensory qualities, with freeze-dried products exhibiting superior preservation of texture and volume compared to oven-dried counterparts.

Colorant Stability

Oven drying often causes significant color degradation due to higher temperature exposure, leading to reduced colorant stability in dehydrated foods. Freeze drying preserves colorant integrity more effectively by using low temperatures and sublimation, minimizing pigment oxidation and degradation.

Oven drying vs Freeze drying for dehydrating. Infographic

cookingdiff.com

cookingdiff.com