Traditional rack drying of fruits relies on natural air circulation and ambient temperatures, resulting in longer drying times and potential nutrient loss. Infrared dehydration uses targeted radiation to rapidly remove moisture, preserving more vitamins and enhancing texture. This method offers energy efficiency and superior product quality compared to conventional drying racks.

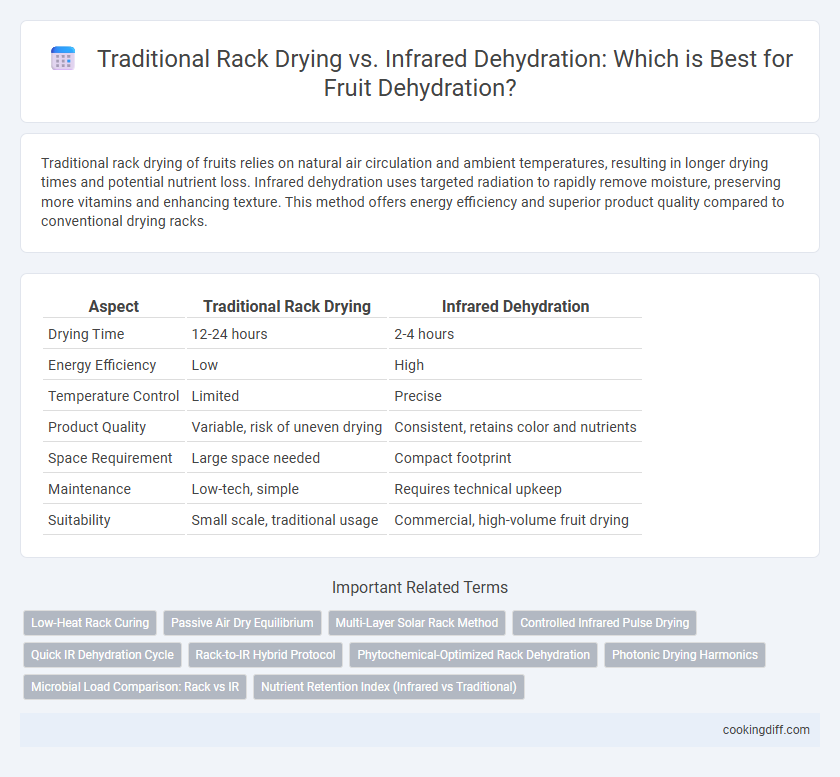

Table of Comparison

| Aspect | Traditional Rack Drying | Infrared Dehydration |

|---|---|---|

| Drying Time | 12-24 hours | 2-4 hours |

| Energy Efficiency | Low | High |

| Temperature Control | Limited | Precise |

| Product Quality | Variable, risk of uneven drying | Consistent, retains color and nutrients |

| Space Requirement | Large space needed | Compact footprint |

| Maintenance | Low-tech, simple | Requires technical upkeep |

| Suitability | Small scale, traditional usage | Commercial, high-volume fruit drying |

Introduction to Fruit Dehydration Methods

How do traditional rack drying and infrared dehydration compare in fruit preservation? Traditional rack drying relies on air circulation and ambient heat to remove moisture, offering a low-cost but slower method. Infrared dehydration uses electromagnetic waves to heat fruits internally, providing faster drying times and improved nutrient retention.

Overview of Traditional Rack Drying

| Traditional rack drying is a time-tested method using natural air flow and ambient temperature to dehydrate fruits, preserving flavor and texture. This process can take several hours to days, depending on the fruit's moisture content and environmental conditions. While cost-effective and simple, traditional drying often results in uneven dehydration and higher risk of microbial growth compared to advanced methods. |

Understanding Infrared Dehydration Technology

Traditional rack drying for fruits relies on natural airflow and ambient temperatures, often resulting in longer drying times and potential nutrient loss. Infrared dehydration technology uses electromagnetic radiation to penetrate fruit layers, accelerating moisture removal while preserving flavor and nutritional content.

Infrared dehydration improves energy efficiency by directly heating water molecules within the fruit, reducing drying duration compared to conventional methods. This technology enables more uniform drying, minimizing surface hardening and maintaining texture quality. As a result, infrared dehydration represents a technologically advanced solution for optimizing fruit preservation and maintaining higher product quality.

Energy Efficiency: Rack Drying vs Infrared Dehydrators

Infrared dehydrators consume significantly less energy compared to traditional rack drying methods due to faster moisture removal and targeted heat application. This efficiency translates into lower operational costs and reduced environmental impact for fruit dehydration.

- Energy Consumption Reduction - Infrared dehydration uses up to 50% less energy than rack drying by minimizing heat loss and drying time.

- Heat Transfer Efficiency - Infrared technology delivers heat directly to fruit surfaces, improving drying uniformity and conserving energy.

- Operational Cost Savings - Reduced energy usage in infrared dehydrators leads to lower electricity bills and maintenance expenses.

Drying Speed and Time Comparison

Infrared dehydration significantly reduces drying time for fruits, often completing the process in less than half the duration required by traditional rack drying methods. Traditional rack drying relies on slower air circulation and ambient heat, which can extend drying times to several hours or even days depending on fruit thickness and moisture content. Faster drying with infrared not only improves productivity but also helps preserve nutritional quality by minimizing heat exposure duration.

Impact on Nutrient Retention and Fruit Quality

Traditional rack drying often results in prolonged exposure to heat, causing significant degradation of heat-sensitive nutrients such as vitamin C and antioxidants in fruits. Infrared dehydration, by contrast, uses rapid heat transfer, preserving more nutrients and maintaining the fruit's natural color and texture better.

- Nutrient Retention - Infrared dehydration retains up to 30% more vitamin C compared to traditional rack drying.

- Drying Time - Traditional rack drying can take several hours longer, increasing nutrient loss through oxidation.

- Fruit Quality - Infrared methods produce fruits with superior texture, color, and flavor preservation.

Flavor and Texture Differences

Traditional rack drying preserves the natural texture of fruits by slowly removing moisture, resulting in a chewier consistency and intensified flavors due to prolonged enzymatic reactions. This method often retains more complex flavor profiles but can cause uneven drying and occasional spoilage.

Infrared dehydration uses radiant heat to swiftly evaporate moisture, maintaining fruit firmness and vibrant color while enhancing sweetness through rapid caramelization of surface sugars. The quick process reduces enzymatic changes, producing a more uniform texture and a brighter, fruit-forward taste.

Safety and Hygiene Considerations

Traditional rack drying exposes fruits to open air, increasing the risk of contamination from dust and microorganisms, while infrared dehydration uses controlled environments that minimize microbial growth. Infrared dehydration allows faster drying times at consistent temperatures, improving overall hygiene by reducing the window for microbial proliferation.

- Risk of Contamination - Rack drying leaves fruits vulnerable to airborne pathogens and insects due to open exposure.

- Temperature Control - Infrared dehydration maintains precise heat levels, ensuring safer and more uniform drying.

- Sanitation - Infrared systems often incorporate enclosed chambers that facilitate easier cleaning and reduce cross-contamination risks.

Infrared dehydration offers superior safety and hygiene by combining rapid drying with a closed, sanitized environment.

Cost Analysis and Accessibility

Traditional rack drying for fruits involves lower upfront equipment costs but requires significant labor and extended drying times, increasing overall operational expenses. Infrared dehydration demands higher initial investment in specialized technology but offers faster processing, reducing labor costs and energy consumption. Accessibility to infrared units may be limited in remote or low-resource areas, making traditional methods more practical despite longer drying durations.

Related Important Terms

Low-Heat Rack Curing

Low-heat rack curing in traditional rack drying preserves fruit texture and flavor by gradually reducing moisture at controlled temperatures, minimizing nutrient loss. Infrared dehydration accelerates moisture removal but may generate uneven heat, risking partial nutrient degradation and altered texture.

Passive Air Dry Equilibrium

Traditional rack drying relies on passive air dry equilibrium, where natural airflow slowly removes moisture from fruits, often resulting in uneven dehydration and longer processing times. Infrared dehydration enhances equilibrium by directly heating fruit surfaces, accelerating moisture removal and improving uniformity without the drawbacks of extended exposure to ambient air.

Multi-Layer Solar Rack Method

The Multi-Layer Solar Rack Method enhances traditional rack drying by utilizing solar energy to efficiently dehydrate fruits across multiple layers, reducing drying time while preserving nutritional quality. Infrared dehydration, though faster, often lacks the energy sustainability and cost-effectiveness inherent in multi-layer solar rack systems designed for large-scale fruit processing.

Controlled Infrared Pulse Drying

Controlled Infrared Pulse Drying (CIPD) offers precise temperature regulation and faster moisture removal compared to traditional rack drying, preserving fruit quality and nutritional content more effectively. This method reduces drying time by up to 50% and lowers energy consumption while maintaining vibrant color and texture in dehydrated fruits.

Quick IR Dehydration Cycle

Quick IR dehydration cycles significantly reduce drying times compared to traditional rack drying methods by using infrared radiation to penetrate fruit tissues rapidly, preserving flavor and nutrients more effectively. This efficient heat transfer accelerates moisture removal while minimizing enzymatic browning and microbial growth, resulting in higher-quality dehydrated fruits with extended shelf life.

Rack-to-IR Hybrid Protocol

The Rack-to-Infrared (IR) Hybrid Protocol combines traditional rack drying with infrared dehydration to optimize moisture removal and preserve fruit quality by reducing drying time and minimizing nutrient loss. This hybrid method enhances energy efficiency and ensures uniform drying, improving texture and flavor retention compared to conventional rack-only techniques.

Phytochemical-Optimized Rack Dehydration

Phytochemical-optimized rack dehydration preserves higher levels of antioxidants and vitamins in fruits by utilizing controlled airflow and moderate temperatures, minimizing nutrient degradation during drying. Unlike infrared dehydration, which can cause uneven heating and loss of sensitive phytochemicals, rack drying maintains fruit integrity and maximizes retention of bioactive compounds essential for health benefits.

Photonic Drying Harmonics

Traditional rack drying relies on convective heat transfer, leading to uneven moisture removal and longer processing times in fruit dehydration. Infrared dehydration employs photonic drying harmonics that penetrate fruit tissue, enhancing moisture evaporation rates, preserving nutritional content, and reducing drying duration by optimizing energy absorption at specific wavelengths.

Microbial Load Comparison: Rack vs IR

Infrared dehydration significantly reduces microbial load on fruits compared to traditional rack drying by utilizing shorter exposure times and higher surface temperatures that inhibit microbial growth. Traditional rack drying often results in uneven drying and prolonged moisture retention, creating conditions conducive to microbial proliferation.

Traditional Rack Drying vs Infrared Dehydration for fruits. Infographic

cookingdiff.com

cookingdiff.com