Sun drying pet food exposes it to inconsistent temperatures and potential contamination from dust, insects, and animals, which can compromise quality and safety. Solar dehydrators provide controlled, uniform heat and protection from environmental contaminants, ensuring more efficient moisture removal and preservation of nutrients. This method enhances shelf life and maintains the nutritional integrity of dehydrated pet food compared to traditional sun drying.

Table of Comparison

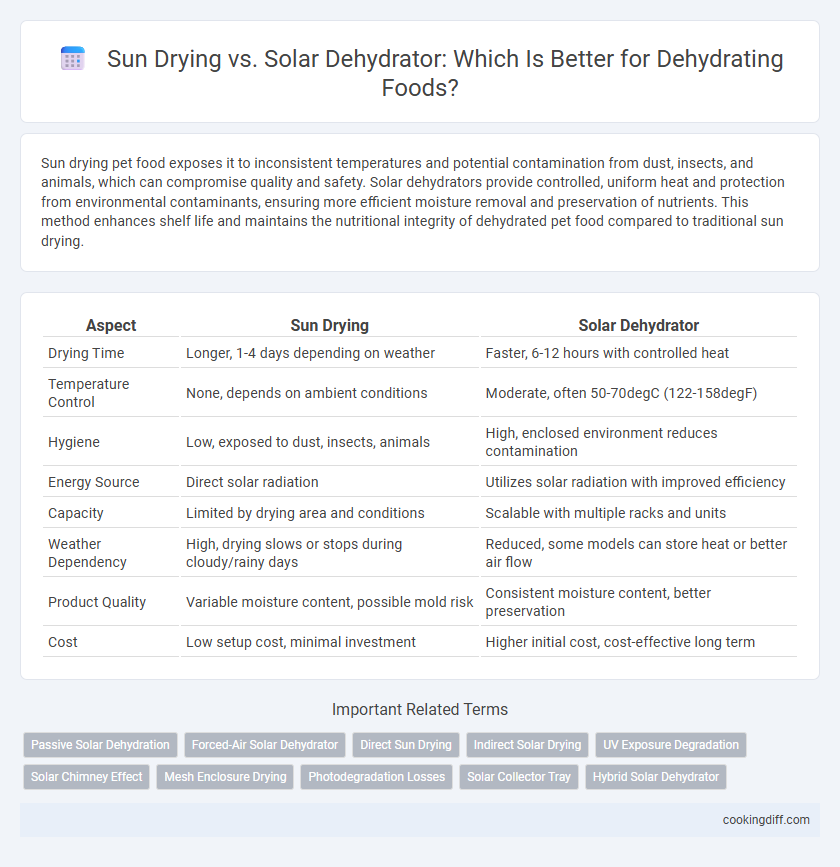

| Aspect | Sun Drying | Solar Dehydrator |

|---|---|---|

| Drying Time | Longer, 1-4 days depending on weather | Faster, 6-12 hours with controlled heat |

| Temperature Control | None, depends on ambient conditions | Moderate, often 50-70degC (122-158degF) |

| Hygiene | Low, exposed to dust, insects, animals | High, enclosed environment reduces contamination |

| Energy Source | Direct solar radiation | Utilizes solar radiation with improved efficiency |

| Capacity | Limited by drying area and conditions | Scalable with multiple racks and units |

| Weather Dependency | High, drying slows or stops during cloudy/rainy days | Reduced, some models can store heat or better air flow |

| Product Quality | Variable moisture content, possible mold risk | Consistent moisture content, better preservation |

| Cost | Low setup cost, minimal investment | Higher initial cost, cost-effective long term |

Introduction to Dehydrating: Sun Drying vs Solar Dehydrator

Dehydrating is a food preservation method that removes moisture to inhibit bacterial growth, extending shelf life. Sun drying and solar dehydrators are two popular techniques, differing mainly in control over drying conditions and efficiency.

- Sun drying - Utilizes natural sunlight and ambient air but depends heavily on weather conditions and can take several days to complete.

- Solar dehydrator - Employs a covered structure that captures and concentrates solar heat for faster, more consistent drying regardless of humidity.

- Efficiency comparison - Solar dehydrators typically reduce drying time by 50-70% compared to traditional sun drying, improving food safety and quality.

How Sun Drying Works for Food Preservation

Sun drying preserves food by harnessing direct sunlight and warm air to evaporate moisture, inhibiting microbial growth and enzymatic reactions. This traditional method requires clear, hot weather and can take several days depending on the type of food and humidity levels.

Solar dehydrators enhance this process by using enclosed chambers and solar collectors to concentrate heat and improve airflow, reducing drying time and contamination risks. These devices maintain consistent temperatures around 50-70degC, optimizing dehydration and preserving nutrients more effectively than open sun drying.

Understanding Solar Dehydrators: Design and Functionality

How do solar dehydrators enhance the efficiency of sun drying in food preservation? Solar dehydrators use enclosed chambers and controlled airflow to accelerate moisture removal compared to traditional open sun drying. Their design typically includes transparent covers and ventilation systems that protect food from contaminants while maximizing drying rates.

Key Differences Between Sun Drying and Solar Dehydration

Sun drying relies on direct exposure to natural sunlight, which can be inconsistent due to weather conditions and offers limited temperature control. In contrast, a solar dehydrator uses a solar collector and enclosed drying chamber to provide a controlled environment with consistent heat and airflow.

Sun drying often results in slower dehydration times and higher risk of contamination from dust and insects. Solar dehydrators enhance food safety, reduce drying time, and improve nutrient retention by maintaining optimal drying temperatures around 50-70degC (122-158degF).

Efficiency Comparison: Drying Times and Consistency

Sun drying typically requires 2 to 4 days depending on weather conditions, often leading to inconsistent moisture removal and potential contamination. Solar dehydrators, utilizing controlled airflow and higher temperatures around 50-70degC, reduce drying times to 12-24 hours while ensuring uniform dehydration. This efficiency improves product safety and shelf life, making solar dehydrators a superior choice for consistent drying outcomes.

Food Safety and Hygiene: Sun Drying vs Solar Dehydrators

Sun drying exposes food to open air, increasing the risk of contamination from dust, insects, and pathogens, compromising food safety and hygiene. Solar dehydrators provide a controlled environment that limits exposure to harmful elements and maintains consistent drying temperatures, reducing microbial growth. Using solar dehydrators enhances food safety by minimizing contamination and preserving the quality of dehydrated products more effectively than traditional sun drying.

Climate and Weather Considerations for Both Methods

| Sun Drying | Relies heavily on consistent, high temperatures and low humidity; best suited for arid, sunny climates where direct sunlight is abundant and weather remains stable. Cloudy or rainy conditions can significantly delay drying times and increase spoilage risks. |

| Solar Dehydrator | Operates efficiently in varied climates by trapping and circulating solar heat, providing protection against wind, insects, and inconsistent weather. Suitable for regions with fluctuating sunlight and humidity, maintaining controlled drying conditions even under less ideal weather. |

Nutrient Retention: Impact of Drying Method

Sun drying often leads to greater nutrient degradation due to prolonged exposure to UV rays and fluctuating temperatures. Solar dehydrators provide a controlled environment that better preserves vitamins and minerals during the drying process.

- Sun drying exposes food to direct sunlight - Ultraviolet rays cause significant breakdown of sensitive nutrients like vitamin C and carotenoids.

- Solar dehydrators regulate temperature and airflow - This reduces nutrient loss by minimizing oxidation and enzymatic reactions.

- Faster drying times in solar dehydrators - Shorter dehydration reduces the duration nutrients are exposed to damaging elements.

Cost, Accessibility, and Sustainability Factors

Sun drying is the most cost-effective and accessible method for dehydrating food, utilizing natural sunlight without any equipment expense. Solar dehydrators require an initial investment but provide faster, more reliable drying while preserving nutrients and reducing contamination risks.

- Cost - Sun drying incurs virtually no upfront costs, whereas solar dehydrators require purchase and occasional maintenance expenses.

- Accessibility - Sun drying is accessible to anyone with sufficient sunlight, making it suitable for rural or low-income areas.

- Sustainability - Both methods are environmentally friendly, but solar dehydrators optimize energy use and decrease food spoilage compared to open sun drying.

Choosing between sun drying and solar dehydrators depends on balancing budget constraints, drying needs, and environmental priorities.

Related Important Terms

Passive Solar Dehydration

Passive solar dehydration uses natural sunlight and airflow to remove moisture from food, preserving nutrients and flavors without electricity. Compared to sun drying, solar dehydrators provide controlled temperature and ventilation, reducing contamination risks and improving drying efficiency.

Forced-Air Solar Dehydrator

Forced-air solar dehydrators provide consistent airflow and controlled drying temperatures, significantly reducing dehydration time and minimizing nutrient loss compared to traditional sun drying. This method effectively prevents contamination from dust and insects, ensuring higher food safety and quality during the dehydration process.

Direct Sun Drying

Direct sun drying exposes food to open sunlight, relying solely on natural heat and airflow to remove moisture, which can lead to uneven drying and potential contamination from dust or insects. This traditional method is cost-effective but less efficient and slower compared to solar dehydrators that offer controlled temperature and hygiene.

Indirect Solar Drying

Indirect solar drying uses solar dehydrators to protect food from direct sunlight and contaminants, improving preservation quality and reducing nutrient loss compared to traditional sun drying. Solar dehydrators maintain controlled airflow and temperature, enhancing dehydration efficiency and extending shelf life of fruits and vegetables.

UV Exposure Degradation

Sun drying exposes food directly to ultraviolet (UV) rays, accelerating nutrient degradation and color loss due to prolonged UV exposure. Solar dehydrators reduce UV exposure by filtering or shielding food items, preserving nutritional quality and appearance while promoting efficient moisture removal.

Solar Chimney Effect

Solar dehydrators utilize the Solar Chimney Effect to enhance airflow and temperature control, accelerating moisture removal compared to traditional sun drying methods. This controlled ventilation increases dehydration efficiency by maintaining consistent heat and reducing contamination risks inherent in open-air sun drying.

Mesh Enclosure Drying

Mesh enclosure drying in sun drying exposes food directly to open air and sunlight, allowing natural evaporation but risking contamination from dust, insects, and uneven drying. Solar dehydrators use mesh trays within a controlled enclosed environment, enhancing airflow and temperature regulation to improve drying efficiency while maintaining food safety and quality.

Photodegradation Losses

Sun drying exposes food directly to ultraviolet rays, increasing the risk of photodegradation losses that degrade nutrients and color. Solar dehydrators minimize these losses by using controlled temperature and indirect sunlight, preserving food quality and extending shelf life.

Solar Collector Tray

Solar collector trays in solar dehydrators provide consistent heat distribution and higher temperatures compared to traditional sun drying, resulting in faster dehydration and improved food preservation. Unlike sun drying, the enclosed design of solar collector trays protects produce from contaminants and unpredictable weather, ensuring safer and more efficient drying.

Sun drying vs Solar dehydrator for dehydrating. Infographic

cookingdiff.com

cookingdiff.com