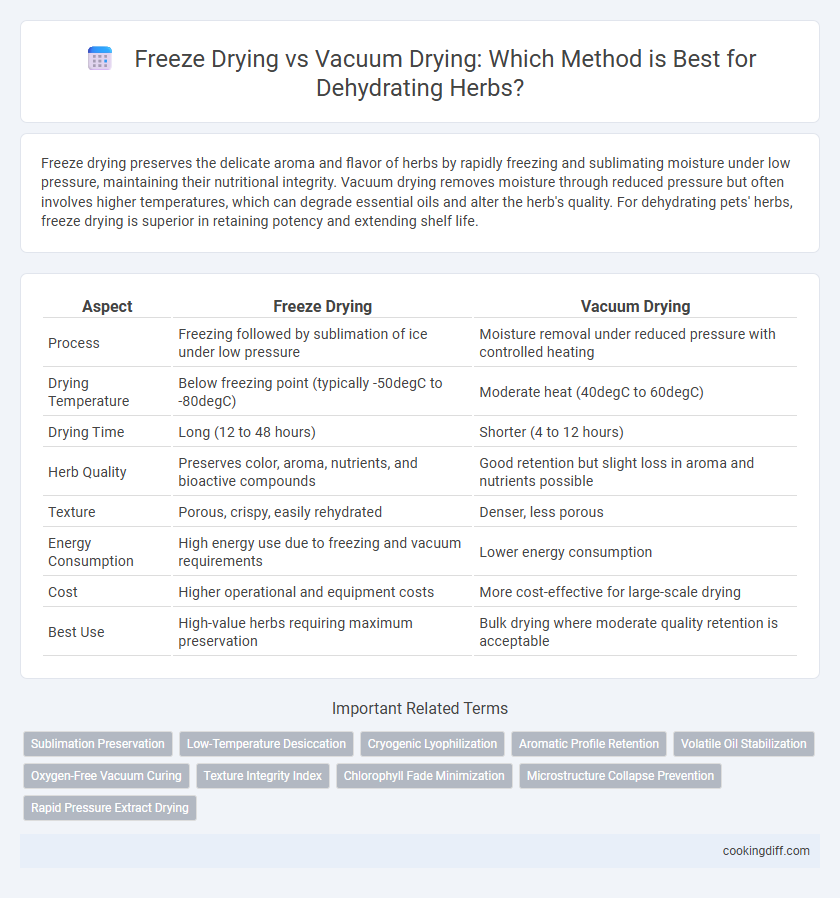

Freeze drying preserves the delicate aroma and flavor of herbs by rapidly freezing and sublimating moisture under low pressure, maintaining their nutritional integrity. Vacuum drying removes moisture through reduced pressure but often involves higher temperatures, which can degrade essential oils and alter the herb's quality. For dehydrating pets' herbs, freeze drying is superior in retaining potency and extending shelf life.

Table of Comparison

| Aspect | Freeze Drying | Vacuum Drying |

|---|---|---|

| Process | Freezing followed by sublimation of ice under low pressure | Moisture removal under reduced pressure with controlled heating |

| Drying Temperature | Below freezing point (typically -50degC to -80degC) | Moderate heat (40degC to 60degC) |

| Drying Time | Long (12 to 48 hours) | Shorter (4 to 12 hours) |

| Herb Quality | Preserves color, aroma, nutrients, and bioactive compounds | Good retention but slight loss in aroma and nutrients possible |

| Texture | Porous, crispy, easily rehydrated | Denser, less porous |

| Energy Consumption | High energy use due to freezing and vacuum requirements | Lower energy consumption |

| Cost | Higher operational and equipment costs | More cost-effective for large-scale drying |

| Best Use | High-value herbs requiring maximum preservation | Bulk drying where moderate quality retention is acceptable |

Introduction to Herb Preservation Methods

Freeze drying and vacuum drying are advanced dehydration techniques widely used for preserving herbs, each offering distinct benefits in maintaining flavor and nutrients. These methods differ primarily in temperature and pressure conditions, impacting the efficiency and quality of herb preservation.

- Freeze Drying - Removes moisture by freezing herbs and applying a vacuum to sublimate ice directly into vapor, preserving delicate flavors and active compounds.

- Vacuum Drying - Extracts moisture at low pressure using mild heat, reducing oxidation and preserving color while slightly affecting texture.

- Preservation Quality - Freeze drying generally retains more volatile oils and nutrients, making it ideal for high-value herbs used in culinary and medicinal applications.

Both methods significantly extend shelf life while maintaining herb quality better than traditional drying techniques.

What Is Freeze Drying for Herbs?

Freeze drying for herbs involves rapidly freezing the plant material and then reducing the surrounding pressure to allow the frozen water in the herbs to sublimate directly from ice to vapor. This method preserves the herbs' flavor, aroma, color, and nutritional content more effectively than traditional drying techniques. The low-temperature process minimizes cell damage, maintaining the herb's potency and extending shelf life significantly.

What Is Vacuum Drying for Herbs?

Vacuum drying for herbs involves removing moisture under reduced pressure, which lowers the boiling point of water and allows drying at lower temperatures. This method preserves the herbs' flavor, color, and essential oils better than traditional drying techniques. Vacuum drying is energy-efficient and effective for delicate herbs sensitive to heat degradation.

Freeze Drying vs Vacuum Drying: Process Overview

| Method | Process Overview |

|---|---|

| Freeze Drying | Freeze drying removes moisture by freezing herbs and then applying a vacuum to sublimate ice directly into vapor, preserving aroma, color, and nutritional content effectively. The process operates at low temperatures, minimizing thermal degradation and maintaining delicate herb structures. |

| Vacuum Drying | Vacuum drying extracts moisture under reduced pressure, allowing evaporation at lower temperatures than conventional drying to reduce heat damage. It offers faster drying times compared to ambient drying, with moderate retention of flavor and nutrients but can cause some cellular damage. |

Impact on Herb Aroma and Flavor

Freeze drying preserves herb aroma and flavor by sublimating water at low temperatures, maintaining volatile oils and active compounds intact. This method results in herbs with a potent fragrance and taste closely matching their fresh counterparts.

Vacuum drying removes moisture under reduced pressure but involves higher temperatures that can degrade delicate aromatic compounds. Consequently, herbs dried this way often exhibit diminished aroma intensity and altered flavor profiles compared to freeze-dried herbs.

Nutritional Retention: Freeze Drying vs Vacuum Drying

Freeze drying preserves up to 97% of the nutritional content in herbs by removing moisture at low temperatures, protecting heat-sensitive vitamins and antioxidants. Vacuum drying involves higher temperatures that can degrade some nutrients, resulting in slightly lower retention compared to freeze drying.

- Freeze Drying - Retains most vitamins and antioxidants by sublimating ice under low temperature and pressure.

- Vacuum Drying - Uses reduced pressure but higher temperatures, potentially diminishing sensitive nutrients.

- Nutritional Retention - Freeze drying generally offers superior preservation of nutritional value over vacuum drying in herbs.

Texture and Color: Comparing Final Results

Freeze drying preserves the vibrant color and delicate texture of herbs by sublimating moisture at low temperatures, maintaining cellular integrity. This method results in herbs that rehydrate quickly and retain their original flavor and appearance more effectively than vacuum drying.

Vacuum drying uses lower pressure and moderate heat to remove moisture, often causing slight color darkening and texture changes due to uneven drying. Herbs processed with vacuum drying may become more brittle and less visually vibrant compared to those freeze dried.

Shelf Life and Storage Differences

Freeze drying preserves herbs by removing moisture at low temperatures, resulting in a longer shelf life of up to 25 years due to minimal nutrient loss and oxidation. Vacuum drying, operating at higher temperatures, typically offers a shelf life of 6 months to 2 years depending on herb type and storage conditions.

Herbs processed through freeze drying require airtight, moisture-proof containers stored in cool, dark environments to maintain quality. Vacuum dried herbs need similar storage but are more sensitive to temperature fluctuations and humidity, which can reduce shelf life. Proper packaging with oxygen absorbers enhances the longevity of both methods while preserving flavor and potency.

Cost and Equipment Considerations

Freeze drying herbs involves higher initial investment and operational costs due to the sophisticated equipment and low-temperature vacuum conditions required. Vacuum drying is generally more affordable and accessible, utilizing simpler equipment with lower energy consumption but may compromise some herb quality.

- Freeze drying equipment cost - Requires expensive machinery with precise temperature and pressure control systems.

- Vacuum drying affordability - Uses less complex, more cost-effective vacuum ovens suitable for small to medium-scale operations.

- Operational expenses - Freeze drying consumes more energy and maintenance resources compared to vacuum drying methods.

Related Important Terms

Sublimation Preservation

Freeze drying preserves herbs by sublimation, turning ice directly into vapor under low temperature and pressure, which retains their flavor, color, and nutrient content more effectively than vacuum drying. Vacuum drying removes moisture through evaporation at slightly higher temperatures, risking the loss of volatile oils and delicate compounds essential for herb quality.

Low-Temperature Desiccation

Freeze drying preserves herbs by sublimating frozen moisture at temperatures below -40degC under vacuum, maintaining volatile oils and nutritional quality through low-temperature desiccation. Vacuum drying operates slightly above freezing, removing water by evaporation under reduced pressure, which risks some thermal degradation but accelerates drying compared to freeze drying.

Cryogenic Lyophilization

Cryogenic lyophilization, a specialized form of freeze drying, preserves the volatile oils and bioactive compounds in herbs more effectively than vacuum drying by rapidly freezing and sublimating water under ultra-low temperatures and pressure. This method minimizes thermal degradation and oxidation, ensuring superior retention of color, aroma, and nutritional value in dried herbs.

Aromatic Profile Retention

Freeze drying preserves the aromatic profile of herbs better than vacuum drying by rapidly removing moisture at low temperatures, minimizing volatile compound loss. Vacuum drying, operating at higher temperatures, often causes greater evaporation of essential oils, leading to diminished aroma intensity.

Volatile Oil Stabilization

Freeze drying effectively preserves volatile oils in herbs by sublimating moisture under low temperature and pressure, minimizing thermal degradation and retaining aromatic compounds. Vacuum drying, while reducing oxidation risks, exposes herbs to higher temperatures that can lead to significant volatile oil loss and altered flavor profiles.

Oxygen-Free Vacuum Curing

Freeze drying preserves herbs by sublimating ice under low temperature and pressure, maintaining their cellular structure and volatile oils without oxidation, while vacuum drying removes moisture through evaporation at reduced pressure but higher temperatures, risking some loss of antioxidants. Oxygen-free vacuum curing enhances both methods by eliminating oxygen exposure, preventing oxidative degradation and preserving color, aroma, and potency of delicate herbs.

Texture Integrity Index

Freeze drying preserves the Texture Integrity Index of herbs significantly better than vacuum drying by removing moisture at low temperatures, which maintains cellular structure and reduces shrinkage. Vacuum drying often leads to a lower Texture Integrity Index due to heat-induced cell collapse and surface hardening, compromising the herb's original texture.

Chlorophyll Fade Minimization

Freeze drying preserves chlorophyll in herbs more effectively by rapidly removing moisture at low temperatures, preventing cell damage and color degradation. Vacuum drying, although reducing drying time, often involves higher temperatures that accelerate chlorophyll fade, resulting in less vibrant herbs.

Microstructure Collapse Prevention

Freeze drying preserves the microstructure of herbs by sublimating water directly from ice to vapor, preventing cellular collapse and retaining cellular integrity. Vacuum drying, while effective at moisture removal, risks microstructure collapse due to elevated temperatures causing cell wall damage and shrinkage.

Freeze drying vs vacuum drying for herbs. Infographic

cookingdiff.com

cookingdiff.com