Vacuum sealers are ideal for quick and simple dehydration tasks, offering efficient air removal for smaller portions and everyday cooking needs. Chamber vacuum machines provide a superior seal by removing air inside a sealed chamber, making them perfect for larger batches and more delicate foods that require consistent vacuum pressure. Choosing between the two depends on the volume of food and precision needed for optimal dehydration results.

Table of Comparison

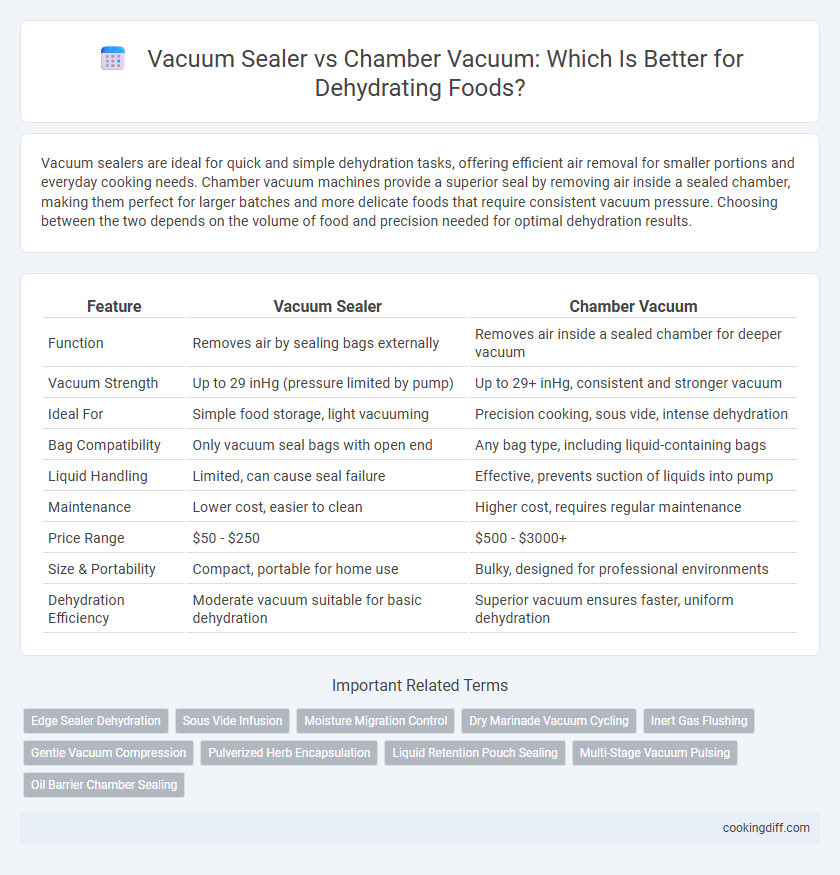

| Feature | Vacuum Sealer | Chamber Vacuum |

|---|---|---|

| Function | Removes air by sealing bags externally | Removes air inside a sealed chamber for deeper vacuum |

| Vacuum Strength | Up to 29 inHg (pressure limited by pump) | Up to 29+ inHg, consistent and stronger vacuum |

| Ideal For | Simple food storage, light vacuuming | Precision cooking, sous vide, intense dehydration |

| Bag Compatibility | Only vacuum seal bags with open end | Any bag type, including liquid-containing bags |

| Liquid Handling | Limited, can cause seal failure | Effective, prevents suction of liquids into pump |

| Maintenance | Lower cost, easier to clean | Higher cost, requires regular maintenance |

| Price Range | $50 - $250 | $500 - $3000+ |

| Size & Portability | Compact, portable for home use | Bulky, designed for professional environments |

| Dehydration Efficiency | Moderate vacuum suitable for basic dehydration | Superior vacuum ensures faster, uniform dehydration |

Introduction to Vacuum Sealers and Chamber Vacuum Sealers

Vacuum sealers remove air from packaging to preserve food freshness and extend shelf life. Chamber vacuum sealers create a vacuum inside a sealed chamber, allowing for airtight sealing of liquids and moist foods without product deformation.

- Vacuum Sealers - Ideal for dry or low-moisture foods, they use external suction to remove air before sealing.

- Chamber Vacuum Sealers - Suitable for high-moisture or liquid-rich foods, they vacuum seal by removing air within a sealed chamber.

- Cooking Applications - Chamber vacuum sealers excel in sous-vide and dehydrating processes due to superior air removal and gentle sealing.

How Each Device Works: Basic Principles

How does a vacuum sealer differ from a chamber vacuum in food dehydration processes? A vacuum sealer removes air by sealing food in a bag with a built-in pump that sucks air out from the outside. In contrast, a chamber vacuum places the entire bag inside a sealed chamber, removing air from both inside and outside the bag, allowing more efficient and uniform dehydration.

Key Differences Between Vacuum Sealers and Chamber Vacuums

Vacuum sealers use external suction to remove air from bags, making them ideal for home use and lightweight foods, while chamber vacuums extract air from a sealed chamber, allowing for sealing of liquids and wet foods without loss of vacuum pressure. Chamber vacuum machines provide a more consistent, stronger vacuum, which preserves food quality longer and prevents freezer burn more effectively than external vacuum sealers. The key differences center on pressure methods, the ability to seal liquids, and suitability for different cooking and storage needs.

Advantages of Vacuum Sealers in Cooking

Vacuum sealers enhance food preservation by removing air, extending the shelf life of ingredients and preventing freezer burn. They maintain flavor and nutritional value, crucial for preparing meals in advance or sous vide cooking.

Home vacuum sealers are typically more affordable and easier to use compared to chamber vacuums, making them ideal for everyday kitchen use. Their compact size fits well in most kitchens without sacrificing sealing efficiency for thin or flexible packaging.

Advantages of Chamber Vacuum Sealers in Culinary Use

Chamber vacuum sealers provide superior vacuum strength and uniform sealing, essential for consistent dehydration in culinary applications. Their ability to handle liquids and moist foods without compromising the seal quality makes them ideal for professional kitchens.

- Enhanced Vacuum Pressure - Chamber vacuum sealers achieve higher vacuum levels for more effective moisture removal during dehydration.

- Batch Processing Efficiency - These sealers can process multiple bags simultaneously, improving kitchen workflow and reducing preparation time.

- Versatility with Liquids - Chamber vacuum sealers effectively seal liquid-rich ingredients without risk of pouch collapse or leakage.

Performance in Dehydrating and Sous Vide Cooking

Vacuum sealers and chamber vacuum machines differ significantly in performance during dehydrating and sous vide cooking. Chamber vacuums provide a stronger, more uniform seal by removing air both inside and outside the bag, enhancing moisture retention and preventing oxidation.

Dehydrating with a chamber vacuum offers faster drying times and better texture preservation by ensuring consistent pressure and reducing air pockets. For sous vide cooking, chamber vacuum sealers create airtight seals that improve heat transfer and flavor infusion. Vacuum sealers typically struggle with liquids, while chamber vacuums efficiently handle wet ingredients, making them ideal for complex cooking techniques.

Usability and Maintenance Considerations

| Vacuum Sealer Usability | Ideal for dry or moist foods, easier for home use due to simple operation and quick sealing process. |

| Vacuum Sealer Maintenance | Requires regular cleaning of the sealing strip and drip tray to prevent residue buildup and ensure proper suction. |

| Chamber Vacuum Usability | Suited for wet or delicate items, offers deeper vacuum levels and better bag flexibility but involves more complex settings. |

| Chamber Vacuum Maintenance | Needs routine oil changes, gasket inspections, and thorough cleaning inside the chamber to maintain performance and seal integrity. |

Cost Comparison and Value for Home Cooks

Vacuum sealers typically cost between $50 and $200, making them an affordable option for home cooks focused on basic food preservation. Chamber vacuum sealers, priced from $400 to over $1,000, offer superior sealing for liquids and extended freshness, providing greater value for serious culinary enthusiasts. The higher initial investment in a chamber vacuum sealer is justified by its enhanced performance and versatility in dehydrating and sous vide cooking.

Which One Best Suits Your Cooking Needs?

Choosing between a vacuum sealer and a chamber vacuum depends on the type of food and cooking method you use. Chamber vacuum sealers handle liquids and moist foods efficiently, while external vacuum sealers are suitable for dry items and smaller kitchens.

- Vacuum Sealer - Ideal for solid, dry foods and quick sealing jobs, commonly used in home kitchens for sous vide cooking.

- Chamber Vacuum - Designed to seal liquids and long-cook meals without crushing delicate ingredients, perfect for professional or frequent use.

- Cooking Needs - Consider moisture content and frequency of use to determine the best vacuum sealing option for your culinary projects.

Selecting the right vacuum sealer enhances food preservation and cooking efficiency based on your specific needs.

Related Important Terms

Edge Sealer Dehydration

Edge sealer dehydration in vacuum sealers ensures airtight packaging by creating a strong, uniform seal that prevents moisture loss and preserves food texture during dehydration. Chamber vacuum machines offer superior edge sealing by equalizing pressure inside and outside the bag, enhancing dehydration efficiency and extending shelf life compared to traditional vacuum sealers.

Sous Vide Infusion

Vacuum sealers create airtight bags by removing air, ideal for sous vide infusion by preserving flavors during slow cooking, while chamber vacuum machines enhance this process with uniform vacuum pressure inside the chamber, ensuring deeper infusion and longer shelf life. For sous vide enthusiasts, chamber vacuum sealers provide superior marinating efficiency and moisture retention, critical for tender, flavorful dishes.

Moisture Migration Control

Vacuum sealers with external suction effectively remove air but may allow moisture migration during deaeration, compromising food texture in dehydrating processes. Chamber vacuum systems create a uniform vacuum environment that prevents moisture migration by equalizing pressure inside and outside the package, preserving food quality and ensuring consistent dehydration results.

Dry Marinade Vacuum Cycling

Vacuum sealers with dry marinade vacuum cycling effectively remove air to enhance flavor infusion while preserving food texture during dehydration, but chamber vacuum sealers provide superior air removal and consistent pressure control, improving marinade absorption and drying efficiency. Chamber vacuum technology enables deeper penetration of dry marinades and faster moisture removal, making it ideal for precise and high-quality dehydrating processes in culinary applications.

Inert Gas Flushing

Vacuum sealers with inert gas flushing prevent oxidation and preserve food color and flavor by replacing oxygen with gases like nitrogen or carbon dioxide, ideal for dehydrated ingredients. Chamber vacuum systems excel in maintaining product integrity by achieving deeper vacuum levels and uniformly infusing inert gases, enhancing shelf life and quality for dehydrated foods.

Gentle Vacuum Compression

Chamber vacuum machines provide gentle vacuum compression ideal for dehydrating delicate foods, preserving texture and flavor without crushing or damaging them. Unlike external vacuum sealers, chamber vacuums evenly remove air from the entire package, preventing moisture loss and maintaining the quality of ingredients during slow drying processes.

Pulverized Herb Encapsulation

Vacuum sealers create an airtight environment for pulverized herb encapsulation, preserving aroma and potency by removing oxygen and moisture, but chamber vacuum machines achieve deeper vacuum levels with uniform pressure distribution, enhancing herb texture and long-term flavor retention. Chamber vacuum systems excel at maintaining volatile oils during dehydration, making them ideal for culinary applications requiring precise encapsulation of powdered herbs.

Liquid Retention Pouch Sealing

Vacuum sealers with chamber technology excel at liquid retention pouch sealing by creating a controlled vacuum environment that prevents liquids from being sucked out during the sealing process. This method ensures optimal moisture preservation for dehydrated foods, unlike external vacuum sealers that risk pouch collapse and liquid loss.

Multi-Stage Vacuum Pulsing

Multi-stage vacuum pulsing in chamber vacuum sealers enhances dehydration by repeatedly removing air and moisture, preserving food texture and flavor more effectively than traditional vacuum sealers. This technology ensures uniform drying and extends shelf life, making it ideal for precision cooking and long-term storage.

Vacuum sealer vs Chamber vacuum for cooking. Infographic

cookingdiff.com

cookingdiff.com