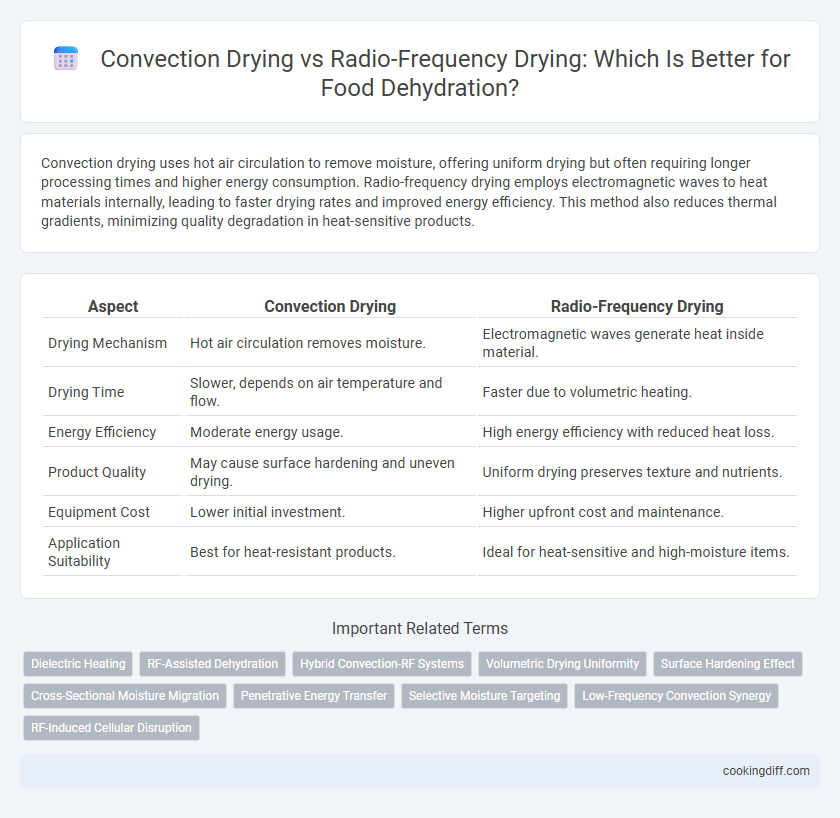

Convection drying uses hot air circulation to remove moisture, offering uniform drying but often requiring longer processing times and higher energy consumption. Radio-frequency drying employs electromagnetic waves to heat materials internally, leading to faster drying rates and improved energy efficiency. This method also reduces thermal gradients, minimizing quality degradation in heat-sensitive products.

Table of Comparison

| Aspect | Convection Drying | Radio-Frequency Drying |

|---|---|---|

| Drying Mechanism | Hot air circulation removes moisture. | Electromagnetic waves generate heat inside material. |

| Drying Time | Slower, depends on air temperature and flow. | Faster due to volumetric heating. |

| Energy Efficiency | Moderate energy usage. | High energy efficiency with reduced heat loss. |

| Product Quality | May cause surface hardening and uneven drying. | Uniform drying preserves texture and nutrients. |

| Equipment Cost | Lower initial investment. | Higher upfront cost and maintenance. |

| Application Suitability | Best for heat-resistant products. | Ideal for heat-sensitive and high-moisture items. |

Introduction to Convection Drying and Radio-Frequency Drying

What are the key differences between convection drying and radio-frequency drying in dehydration processes? Convection drying uses hot air to remove moisture from materials through heat transfer and evaporation, making it suitable for a variety of food products and pharmaceuticals. Radio-frequency drying employs electromagnetic waves to generate heat internally, offering faster drying rates and improved energy efficiency for certain heat-sensitive materials.

Principles of Convection Drying in Food Dehydration

Convection drying in food dehydration relies on the transfer of heat through hot air circulation to evaporate moisture from food surfaces. This method ensures uniform drying by maintaining consistent airflow and temperature control around the product.

- Heat Transfer by Hot Air - Hot air circulates over food, promoting moisture evaporation from the surface.

- Temperature and Airflow Control - Regulated temperature and airflow optimize drying rate and product quality.

- Surface Moisture Evaporation - Moisture is removed primarily through evaporation at the food-air interface.

Fundamentals of Radio-Frequency Drying Technology

Radio-frequency drying utilizes electromagnetic waves to heat materials volumetrically, resulting in faster and more uniform moisture removal compared to convection drying, which relies on heat transfer through hot air. This technology enhances drying efficiency and quality by reducing processing time and minimizing thermal degradation.

- Electromagnetic Wave Penetration - Radio-frequency drying uses radio waves that penetrate the material, heating internal moisture directly for uniform drying.

- Volumetric Heating Mechanism - Unlike convection drying's surface heat transfer, RF heats the entire volume simultaneously, speeding up dehydration.

- Energy Efficiency - RF drying reduces energy consumption due to rapid moisture removal and less heat loss to the environment.

Key Differences: Heat Transfer Mechanisms

| Convection Drying | Radio-frequency Drying |

|---|---|

| Uses hot air circulation to transfer heat primarily through convection, heating the product's surface followed by moisture evaporation. | Employs electromagnetic waves to generate heat volumetrically within the product, causing internal water molecules to vibrate and evaporate moisture uniformly. |

| Heat transfer is slower and dependent on air temperature and velocity, leading to potential surface hardening or case hardening in sensitive products. | Heat transfer is rapid and volumetric, reducing drying time and minimizing quality degradation caused by uneven heating. |

| Effective for thin or porous materials where surface drying is sufficient but less efficient for dense or thick samples. | Suitable for dense or thick materials due to deep penetration of radio-frequency waves, enabling uniform moisture removal. |

Energy Efficiency Comparison

Convection drying typically consumes more energy due to prolonged drying times and the continuous operation of heating elements and fans. Radio-frequency drying uses electromagnetic waves to generate heat internally, resulting in faster drying and lower overall energy consumption.

Energy efficiency in radio-frequency drying can be up to 30-50% higher compared to convection drying, making it more cost-effective for large-scale dehydration processes. However, convection drying remains widely used due to its simplicity and lower initial equipment costs despite higher operational energy demands.

Impact on Nutrient Retention and Food Quality

Convection drying often results in higher nutrient degradation due to prolonged exposure to heat and oxygen, compromising food quality. Radio-frequency drying preserves more nutrients by rapidly heating the product internally, reducing drying time and minimizing thermal damage.

- Nutrient Retention - Radio-frequency drying maintains higher levels of vitamins and antioxidants compared to convection drying.

- Texture and Appearance - Foods dried with radio-frequency retain better texture, color, and structural integrity.

- Drying Efficiency - Radio-frequency drying accelerates moisture removal, limiting nutrient loss and quality deterioration.

Radio-frequency drying offers superior preservation of nutritional and sensory attributes over convection drying methods.

Drying Time and Throughput Analysis

Convection drying typically requires longer drying times, ranging from several hours to even days depending on the material's moisture content and drying temperature, which limits throughput efficiency. Radio-frequency drying significantly reduces drying time to minutes or a few hours by heating the material volumetrically, enhancing throughput capacity for large-scale industrial applications.

The faster drying time of radio-frequency drying minimizes thermal degradation and preserves product quality better than convection drying, which relies on surface heat transfer and is slower. However, convection drying systems are generally simpler and less expensive, making them suitable for smaller batches with lower throughput demands. Optimizing throughput involves balancing drying time with energy consumption, product characteristics, and production scale.

Scalability and Cost Considerations

Convection drying offers scalable solutions suitable for large-scale operations due to its straightforward equipment and lower initial investment costs. Radio-frequency drying, while more expensive upfront, provides faster drying times and higher energy efficiency, which can reduce long-term operational expenses. Cost considerations favor convection drying for budget-conscious projects, whereas radio-frequency drying suits businesses prioritizing speed and product quality at a higher scale.

Typical Applications in the Food Industry

Convection drying is widely used in the food industry for dehydrating products like fruits, vegetables, and herbs due to its cost-effectiveness and ability to maintain product quality. It is ideal for applications requiring uniform drying at controlled temperatures, such as drying sliced apples and leafy greens.

Radio-frequency drying offers faster moisture removal and is commonly applied in drying high-moisture foods like meat, seafood, and dairy products. This method enhances drying efficiency and preserves nutritional content in foods such as shrimp and cheese.

Related Important Terms

Dielectric Heating

Radio-frequency drying leverages dielectric heating to generate volumetric heat within the material, resulting in faster moisture removal and more uniform drying compared to convection drying, which relies on surface heat transfer and air flow. The dielectric properties of the product determine the efficiency of radio-frequency drying, making it especially effective for materials with higher moisture content and dielectric constant.

RF-Assisted Dehydration

RF-assisted dehydration leverages radio-frequency electromagnetic waves to penetrate materials, generating uniform internal heat that accelerates moisture removal more efficiently than conventional convection drying. This method reduces drying time and energy consumption while preserving the quality and nutritional value of dehydrated products.

Hybrid Convection-RF Systems

Hybrid convection-radio frequency systems combine the deep volumetric heating of radio-frequency drying with the efficient surface moisture removal of convection drying, resulting in faster dehydration times and improved product quality. This integration optimizes energy consumption and ensures uniform drying, minimizing thermal degradation and preserving nutritional content in food products.

Volumetric Drying Uniformity

Radio-frequency drying provides superior volumetric drying uniformity compared to convection drying by penetrating moisture throughout the product, ensuring even heat distribution and minimizing surface over-drying. Convection drying relies on hot air contact, often resulting in uneven moisture removal and longer drying times due to surface-based heat transfer limitations.

Surface Hardening Effect

Convection drying often causes significant surface hardening due to prolonged exposure to hot air, which creates a dense outer layer that impedes moisture removal. In contrast, radio-frequency drying minimizes surface hardening by volumetrically heating the product, enabling more uniform moisture evaporation and preserving texture integrity.

Cross-Sectional Moisture Migration

Convection drying relies on hot air to remove surface moisture, resulting in slower and uneven cross-sectional moisture migration compared to radio-frequency drying, which uses electromagnetic waves to generate volumetric heating and promote uniform internal moisture evaporation. Radio-frequency drying significantly reduces drying time while maintaining product quality by enhancing internal moisture diffusion across the cross-section.

Penetrative Energy Transfer

Convection drying relies on hot air to transfer heat primarily through surface convection, resulting in slower penetration and uneven moisture removal. Radio-frequency drying employs electromagnetic waves that generate heat volumetrically within the material, enabling rapid and uniform energy transfer throughout the product.

Selective Moisture Targeting

Convection drying removes moisture through heated air circulation, offering uniform drying but often leading to slower moisture removal and potential quality degradation. Radio-frequency drying uses electromagnetic waves to selectively target internal moisture, enabling faster, energy-efficient dehydration with improved retention of nutritional and sensory properties.

Low-Frequency Convection Synergy

Low-frequency convection synergy combines airflow at lower frequencies with controlled heat distribution, enhancing moisture removal efficiency compared to conventional convection drying. This technique reduces drying time and preserves product quality better than standalone radio-frequency drying by optimizing thermal penetration and minimizing surface overheating.

Convection drying vs Radio-frequency drying for dehydrating. Infographic

cookingdiff.com

cookingdiff.com