Stovetop drying citrus slices often leads to uneven moisture removal and potential burning due to direct heat exposure. Dehydrating with airflow regulation ensures consistent drying by maintaining optimal temperature and air circulation, preserving the fruit's flavor and texture. Controlled airflow prevents mold growth and extends shelf life, making it the superior method for dehydrating citrus slices.

Table of Comparison

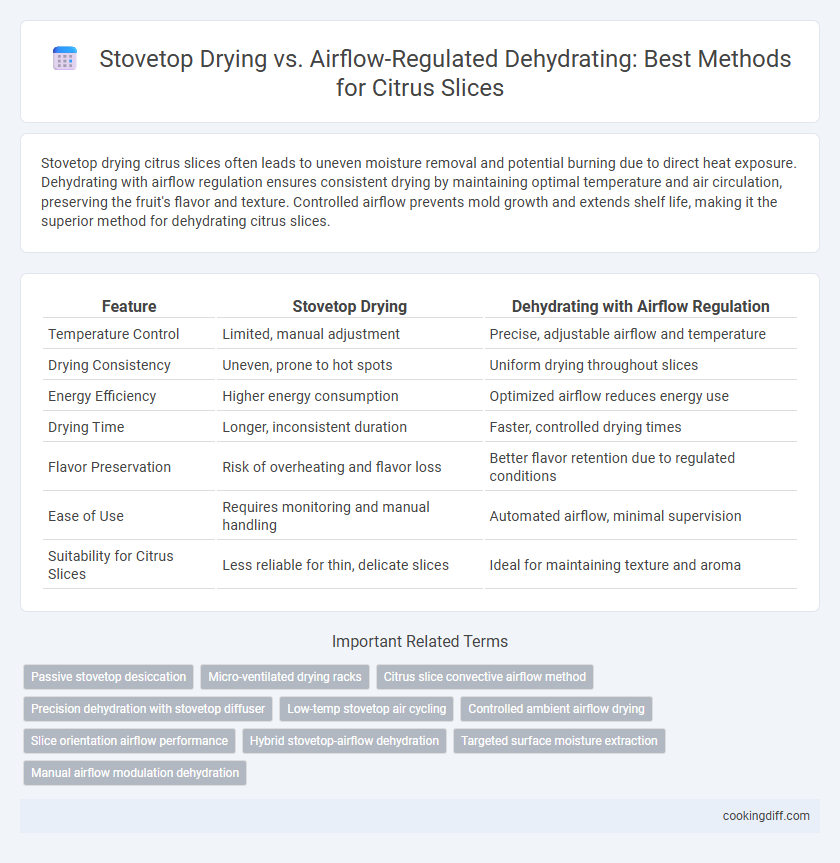

| Feature | Stovetop Drying | Dehydrating with Airflow Regulation |

|---|---|---|

| Temperature Control | Limited, manual adjustment | Precise, adjustable airflow and temperature |

| Drying Consistency | Uneven, prone to hot spots | Uniform drying throughout slices |

| Energy Efficiency | Higher energy consumption | Optimized airflow reduces energy use |

| Drying Time | Longer, inconsistent duration | Faster, controlled drying times |

| Flavor Preservation | Risk of overheating and flavor loss | Better flavor retention due to regulated conditions |

| Ease of Use | Requires monitoring and manual handling | Automated airflow, minimal supervision |

| Suitability for Citrus Slices | Less reliable for thin, delicate slices | Ideal for maintaining texture and aroma |

Introduction to Citrus Slice Drying Methods

Stovetop drying of citrus slices involves placing thinly cut fruit on a low heat source, relying on direct heat to remove moisture slowly. This method requires constant attention to avoid burning and uneven drying, often resulting in inconsistent texture.

Dehydrating with airflow regulation uses controlled temperature and airflow to evenly remove moisture from citrus slices, preserving flavor and preventing spoilage. This technique enhances drying efficiency and maintains the natural aroma and color of the fruit.

Overview of Stovetop Drying for Citrus Slices

How effective is stovetop drying for citrus slices compared to airflow-regulated dehydration? Stovetop drying involves placing citrus slices on a low heat source, which can lead to uneven drying due to inconsistent temperature control. This method lacks the precise airflow regulation found in modern dehydrators, often resulting in longer drying times and potential loss of flavor and nutrients.

Principles of Dehydrating with Airflow Regulation

Dehydrating citrus slices using airflow regulation ensures even moisture removal and prevents enzymatic browning by maintaining consistent temperatures and humidity levels. Stovetop drying lacks precise airflow control, often resulting in uneven drying and potential quality degradation of citrus slices.

- Airflow Regulation - Controls moisture evaporation rate, enhancing drying uniformity and preserving flavor and nutrients.

- Temperature Consistency - Maintains optimal heat for citrus slices, preventing overheating and nutrient loss.

- Humidity Control - Reduces the risk of mold growth and enzymatic reactions by balancing moisture levels during dehydration.

Efficiency Comparison: Stovetop vs. Airflow Dehydrators

Stovetop drying of citrus slices often results in uneven dehydration due to inconsistent temperature control, leading to potential moisture retention and spoilage. Airflow dehydrators provide regulated circulation and precise temperature settings, enhancing drying efficiency and preserving flavor.

Dehydrators with airflow regulation reduce drying time by evenly distributing heat, which prevents the need for frequent monitoring and manual adjustments common in stovetop methods. This consistent environment minimizes nutrient loss and maintains the citrus slices' vibrant color and texture. Consequently, airflow dehydrators achieve higher quality and energy-efficient results compared to traditional stovetop drying.

Flavor and Nutrient Retention in Citrus Slices

Dehydrating citrus slices using airflow regulation preserves essential oils and vitamin C more effectively than stovetop drying, which often exposes slices to uneven heat and moisture, leading to nutrient loss. Controlled airflow ensures consistent drying, maintaining the vibrant flavor and aroma unique to fresh citrus. Stovetop drying risks caramelization and bitterness, compromising both taste and the antioxidant properties of the fruit.

Texture Differences: Stovetop Drying vs. Regulated Airflow

| Method | Texture Outcome |

| Stovetop Drying | Produces unevenly textured citrus slices with chewy edges and often retains moisture pockets, leading to potential brittleness or sogginess. The direct heat causes rapid drying, which can result in tougher and less uniformly dried slices. |

| Dehydrating with Airflow Regulation | Yields uniformly crisp and consistently dried citrus slices, as controlled airflow optimizes moisture removal and prevents surface hardening. This method maintains the natural structure and enhances a pleasant, even crunch. |

Equipment and Setup Requirements

Stovetop drying citrus slices requires a heavy-bottomed pan and low, consistent heat to prevent burning and uneven drying. Dehydrating with airflow regulation involves specialized equipment such as a food dehydrator with adjustable fan speed and temperature controls, ensuring uniform moisture removal. The setup for airflow-regulated dehydrators enables optimal drying conditions by maintaining steady air circulation and heat distribution, resulting in higher quality citrus slices.

Energy Consumption and Cost Analysis

Stovetop drying of citrus slices consumes more energy per batch due to uneven heat distribution and longer drying times compared to dehydrators with airflow regulation. Devices with controlled airflow enhance drying efficiency, reducing both energy consumption and overall operational costs.

- Energy Consumption - Dehydrators with regulated airflow use approximately 30-40% less electricity than stovetop drying methods.

- Cost Efficiency - Lower energy use in airflow-regulated dehydrators translates to decreased electricity bills over time.

- Drying Consistency - Controlled airflow ensures uniform moisture extraction, minimizing product spoilage and waste, which further cuts costs.

Best Practices for Perfectly Dried Citrus Slices

Stovetop drying of citrus slices often results in uneven dehydration due to inconsistent heat distribution, whereas dehydrating with airflow regulation ensures uniform drying and preserves flavor. Controlled airflow optimizes moisture removal, preventing mold growth and maintaining the fruit's vibrant color and aroma.

- Consistent Temperature Control - Regulating heat during dehydration prevents over-drying or under-drying of citrus slices.

- Uniform Airflow Distribution - Even circulation eliminates hotspots and promotes balanced moisture evaporation across all slices.

- Extended Shelf Life - Proper airflow reduces residual moisture, decreasing spoilage and enhancing storage durability.

Applying these best practices guarantees perfectly dried citrus slices ideal for culinary and decorative uses.

Related Important Terms

Passive stovetop desiccation

Passive stovetop desiccation of citrus slices relies on gentle heat without forced airflow, preserving natural oils but often resulting in uneven drying and longer dehydration times. In contrast, dehydrating with airflow regulation ensures consistent moisture removal and uniform texture by optimizing air circulation and temperature control.

Micro-ventilated drying racks

Micro-ventilated drying racks enhance airflow regulation during stovetop drying, ensuring even dehydration of citrus slices by preventing excessive moisture buildup and promoting uniform drying. This method optimizes texture and flavor retention compared to traditional stovetop drying without airflow control.

Citrus slice convective airflow method

Citrus slice convective airflow drying efficiently removes moisture by circulating warm air evenly around the slices, preserving flavor and preventing uneven dehydration common in stovetop drying. This method enhances texture and retains essential oils by maintaining consistent airflow and temperature control throughout the drying process.

Precision dehydration with stovetop diffuser

Using a stovetop diffuser for citrus slices enables precision dehydration by evenly distributing heat and preventing scorching, which preserves flavor and nutritional content. Airflow regulation in dehydrators offers controlled moisture removal but often lacks the immediate temperature adjustments achievable with stovetop drying methods.

Low-temp stovetop air cycling

Low-temp stovetop air cycling maintains consistent airflow and gentle heat, preserving the delicate oils and flavors in citrus slices during dehydration. This method enhances moisture removal efficiency while preventing overheating and nutrient loss, outperforming traditional stovetop drying without airflow regulation.

Controlled ambient airflow drying

Controlled ambient airflow drying in dehydrating citrus slices ensures consistent moisture removal by maintaining optimal airflow and temperature, preventing uneven drying and mold growth often seen in stovetop drying. This method enhances flavor retention and texture by reducing drying time and minimizing heat stress on delicate citrus tissues.

Slice orientation airflow performance

Stovetop drying often results in uneven dehydration of citrus slices due to limited airflow circulation and inconsistent heat distribution, causing variations in dryness and texture. In contrast, dehydrating with airflow regulation ensures optimal slice orientation and uniform airflow performance, promoting even moisture removal and preserving the citrus's natural flavor and color.

Hybrid stovetop-airflow dehydration

Hybrid stovetop-airflow dehydration combines controlled heat from the stovetop with precise airflow regulation to evenly remove moisture from citrus slices, preserving essential oils and vibrant color. This method minimizes drying time compared to traditional stovetop drying alone while enhancing texture and flavor retention through consistent airflow management.

Targeted surface moisture extraction

Stovetop drying removes moisture from citrus slices through direct heat, often resulting in uneven dehydration and potential surface caramelization. Dehydrating with airflow regulation targets surface moisture extraction more precisely, promoting uniform drying and preserving the fruit's natural flavor and texture.

Stovetop drying vs Dehydrating with airflow regulation for citrus slices. Infographic

cookingdiff.com

cookingdiff.com