Air drying relies on natural airflow and ambient temperature to remove moisture from materials, making it a cost-effective but slower method that may be influenced by environmental conditions. Vacuum drying uses reduced pressure to lower the boiling point of water, enabling faster drying at lower temperatures, which preserves the quality and nutrients of heat-sensitive products. Selecting between air drying and vacuum drying depends on factors such as product sensitivity, drying time requirements, and energy consumption priorities.

Table of Comparison

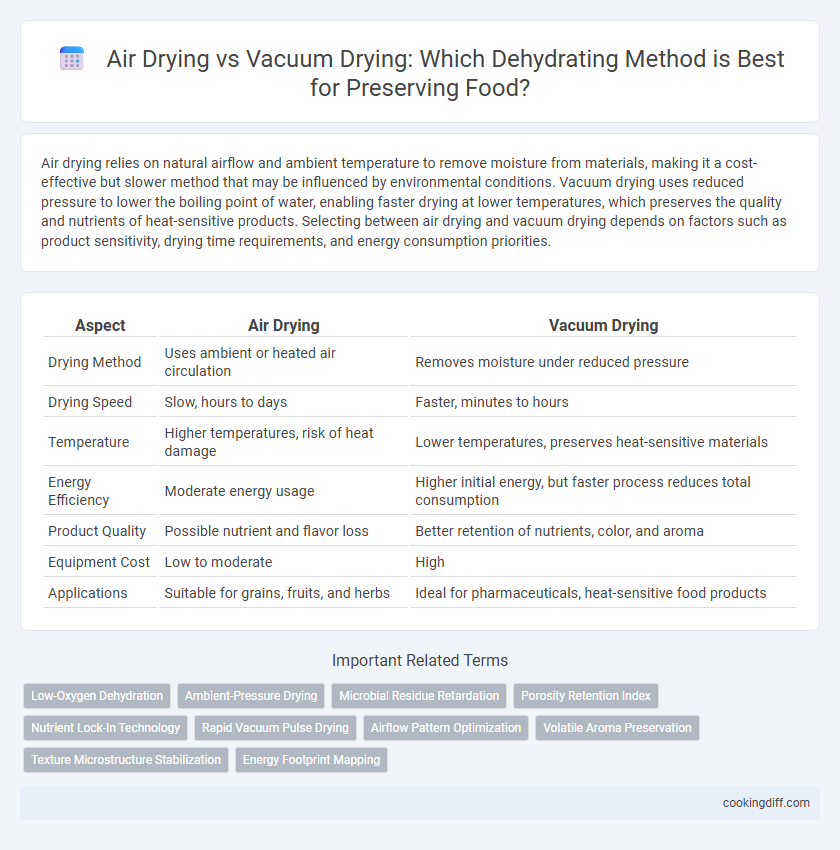

| Aspect | Air Drying | Vacuum Drying |

|---|---|---|

| Drying Method | Uses ambient or heated air circulation | Removes moisture under reduced pressure |

| Drying Speed | Slow, hours to days | Faster, minutes to hours |

| Temperature | Higher temperatures, risk of heat damage | Lower temperatures, preserves heat-sensitive materials |

| Energy Efficiency | Moderate energy usage | Higher initial energy, but faster process reduces total consumption |

| Product Quality | Possible nutrient and flavor loss | Better retention of nutrients, color, and aroma |

| Equipment Cost | Low to moderate | High |

| Applications | Suitable for grains, fruits, and herbs | Ideal for pharmaceuticals, heat-sensitive food products |

Introduction to Dehydration Methods

Air drying and vacuum drying are two prevalent dehydration methods used to remove moisture from various materials. Air drying relies on circulating hot air to evaporate water, making it a cost-effective and straightforward technique.

Vacuum drying removes moisture under reduced pressure, lowering the boiling point of water and preserving heat-sensitive substances. This method enhances drying speed and quality, especially for delicate or thermally sensitive products.

What is Air Drying in Food Dehydration?

Air drying in food dehydration involves removing moisture from food by exposing it to warm, dry air. This method relies on natural or forced air circulation to evaporate water content, preserving the food's texture and flavor.

Air drying is a traditional and energy-efficient technique commonly used for fruits, vegetables, and herbs. It operates at lower temperatures compared to vacuum drying, reducing the risk of nutrient loss and food shrinkage. The process is slower but maintains food quality by minimizing heat damage and oxidation.

What is Vacuum Drying in Food Dehydration?

Vacuum drying in food dehydration involves removing moisture from food under reduced pressure, significantly lowering the boiling point of water and preserving heat-sensitive nutrients and flavors. This method accelerates the drying process while maintaining the food's original color, texture, and nutritional value better than traditional air drying. Vacuum drying is especially effective for delicate foods like fruits, herbs, and pharmaceuticals, where quality retention is crucial.

Key Differences Between Air Drying and Vacuum Drying

Air drying removes moisture from materials using ambient air circulation, making it an energy-efficient method suitable for heat-sensitive products but often slower. It relies on natural evaporation, which can lead to uneven drying and potential microbial growth if not properly controlled.

Vacuum drying lowers the pressure around the material, enabling moisture to evaporate at lower temperatures and preserving heat-sensitive compounds more effectively. This method ensures faster drying times, uniform moisture removal, and reduced oxidation risk, making it ideal for pharmaceuticals and delicate food products.

Efficiency and Speed: Air Drying vs Vacuum Drying

Air drying is a slower dehydration method that relies on ambient air circulation and is less energy-intensive, making it suitable for less moisture-sensitive materials. Vacuum drying significantly speeds up the process by lowering the pressure to reduce boiling points, enhancing efficiency for heat-sensitive and high-moisture content products.

- Energy Consumption - Air drying uses less energy overall but requires longer drying times, potentially increasing operational costs.

- Drying Speed - Vacuum drying accelerates moisture removal by reducing pressure, enabling faster dehydration.

- Product Quality - Vacuum drying better preserves texture and nutrients due to lower temperature exposure.

Choosing between air drying and vacuum drying depends on the balance of speed, energy efficiency, and product sensitivity.

Nutrient Preservation: Which Method is Better?

Vacuum drying preserves nutrients more effectively than air drying by minimizing oxidation and reducing heat exposure. Nutrient retention in heat-sensitive vitamins such as vitamin C and B-complex is significantly higher with vacuum drying.

- Oxidation Reduction - Vacuum drying operates under low pressure, decreasing oxygen exposure and preserving antioxidants and vitamins.

- Temperature Control - Lower drying temperatures in vacuum drying prevent thermal degradation of sensitive nutrients.

- Retention of Phytochemicals - Vacuum drying better maintains bioactive compounds and phytochemicals compared to conventional air drying.

Effects on Texture, Flavor, and Appearance

How do air drying and vacuum drying compare in their effects on texture, flavor, and appearance during dehydration? Air drying often results in a chewier texture and can cause slight flavor oxidation, while vacuum drying preserves a more natural flavor profile and maintains a tender texture. Vacuum drying also enhances appearance by minimizing discoloration and shrinkage compared to the more exposed air drying method.

Equipment and Cost Comparison

Air drying equipment typically involves simple setups like drying racks or heated chambers, offering a cost-effective solution with minimal maintenance expenses. Vacuum drying requires more advanced machinery, such as vacuum pumps and sealed chambers, resulting in higher initial investment and operational costs. Comparing overall expenses, air drying is more affordable but less efficient for moisture-sensitive materials, while vacuum drying offers superior dehydration quality at a premium price.

Best Uses for Air Drying and Vacuum Drying

| Drying Method | Best Uses |

|---|---|

| Air Drying | Ideal for drying herbs, fruits, and vegetables where preservation of natural flavor and color is important. Suitable for small-scale or home dehydration due to low cost and simplicity. Works best in environments with good airflow and moderate humidity levels. |

| Vacuum Drying | Optimal for heat-sensitive materials such as pharmaceuticals, food powders, and delicate plant extracts. Preserves nutritional content and structural integrity by drying at lower temperatures under reduced pressure. Highly effective in industrial applications requiring fast drying with minimal oxidation. |

Related Important Terms

Low-Oxygen Dehydration

Low-oxygen dehydration techniques like vacuum drying significantly reduce oxidation by removing air pressure, preserving nutritional value and color more effectively than conventional air drying. Vacuum drying operates under low oxygen conditions, enhancing the retention of heat-sensitive compounds and improving shelf life in dehydrated products.

Ambient-Pressure Drying

Ambient-pressure drying methods like air drying rely on natural air flow and moderate temperatures to remove moisture, preserving product integrity without specialized equipment. Vacuum drying, although effective for moisture removal at lower temperatures, requires reduced pressure systems, making ambient-pressure air drying more energy-efficient and cost-effective for many dehydration applications.

Microbial Residue Retardation

Air drying and vacuum drying both reduce microbial residue, but vacuum drying offers superior microbial residue retardation by lowering oxygen exposure and moisture content more effectively. This method inhibits microbial growth faster and preserves food safety and quality compared to traditional air drying.

Porosity Retention Index

Air drying maintains a higher Porosity Retention Index compared to vacuum drying, preserving the cellular structure and enhancing rehydration capabilities. Vacuum drying, while faster, often reduces porosity due to cell collapse under low pressure, affecting texture and moisture absorption.

Nutrient Lock-In Technology

Air drying preserves nutrients by slowly removing moisture at ambient temperatures, while Vacuum drying employs reduced pressure to lower boiling points, enhancing nutrient retention through Nutrient Lock-In Technology. This technology minimizes thermal degradation and oxidation, ensuring maximum preservation of vitamins, minerals, and antioxidants during dehydration.

Rapid Vacuum Pulse Drying

Rapid Vacuum Pulse Drying accelerates moisture removal by cyclically reducing pressure, enhancing water vapor diffusion compared to traditional air drying methods that rely solely on ambient airflow and temperature. This technique preserves nutritional quality and texture by minimizing thermal exposure and oxidation, outperforming standard vacuum drying in efficiency and product integrity.

Airflow Pattern Optimization

Air drying achieves dehydration by optimizing airflow patterns to enhance moisture removal through consistent circulation, whereas vacuum drying relies on reduced pressure to lower the boiling point of water, resulting in faster drying times but requires careful airflow control to prevent uneven dehydration. Effective airflow pattern optimization in both methods ensures uniform drying, reduces processing time, and maintains product quality by minimizing heat damage and moisture retention.

Volatile Aroma Preservation

Air drying preserves volatile aromas more effectively due to its gentle, natural evaporation process, minimizing the loss of fragrance compounds during dehydration. Vacuum drying reduces aroma degradation by lowering pressure and drying temperature, which helps retain volatile oils better than conventional heat-based methods.

Texture Microstructure Stabilization

Air drying preserves food texture by slowly removing moisture, maintaining cell structure and minimizing microstructural damage, while vacuum drying accelerates dehydration under low pressure, reducing oxidation and better stabilizing microstructure by preventing cell collapse and preserving porosity essential for quality rehydration.

Air drying vs Vacuum drying for dehydrating. Infographic

cookingdiff.com

cookingdiff.com