When dehydrating pet treats, stainless steel trays offer superior durability and are less likely to retain odors or stains compared to plastic trays. Plastic trays may be more affordable but can warp under high heat and absorb moisture, potentially affecting the quality of dehydrated food. Choosing stainless steel ensures safer, long-lasting use and better hygiene for pet treat preparation.

Table of Comparison

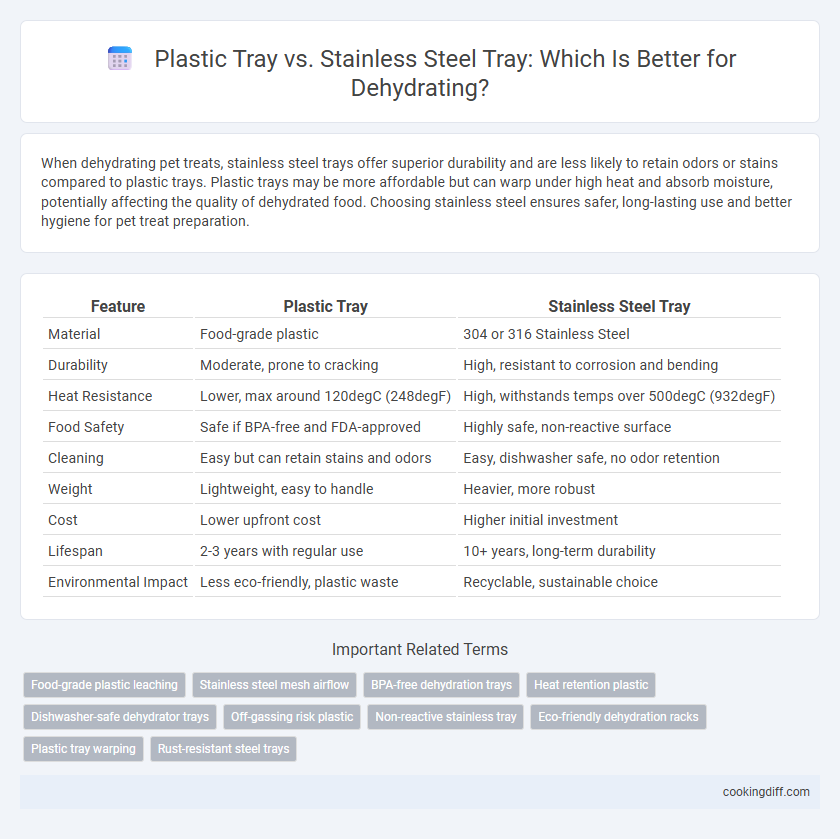

| Feature | Plastic Tray | Stainless Steel Tray |

|---|---|---|

| Material | Food-grade plastic | 304 or 316 Stainless Steel |

| Durability | Moderate, prone to cracking | High, resistant to corrosion and bending |

| Heat Resistance | Lower, max around 120degC (248degF) | High, withstands temps over 500degC (932degF) |

| Food Safety | Safe if BPA-free and FDA-approved | Highly safe, non-reactive surface |

| Cleaning | Easy but can retain stains and odors | Easy, dishwasher safe, no odor retention |

| Weight | Lightweight, easy to handle | Heavier, more robust |

| Cost | Lower upfront cost | Higher initial investment |

| Lifespan | 2-3 years with regular use | 10+ years, long-term durability |

| Environmental Impact | Less eco-friendly, plastic waste | Recyclable, sustainable choice |

Introduction to Dehydrating: Why Tray Material Matters

Tray material plays a crucial role in the efficiency and safety of dehydrating food. Choosing between plastic and stainless steel trays affects temperature control, hygiene, and durability during the dehydration process.

- Thermal Conductivity - Stainless steel trays distribute heat evenly, reducing dehydration time compared to plastic trays.

- Hygiene and Safety - Stainless steel is non-porous and easier to sanitize, preventing bacterial growth better than plastic trays.

- Durability - Stainless steel trays are resistant to warping and cracking under heat, unlike many plastic trays.

Understanding the benefits of each tray type enhances the quality and safety of dehydrated foods.

Overview: Plastic Trays vs Stainless Steel Trays

Plastic trays for dehydrating are lightweight, cost-effective, and resistant to corrosion, making them suitable for home use. Stainless steel trays offer superior durability, are non-reactive, and provide even heat distribution for consistent dehydration results.

Plastic trays can warp or degrade over time when exposed to high temperatures, limiting their lifespan compared to stainless steel trays. Stainless steel trays withstand high temperatures without deforming, ensuring long-term reliability and easy cleaning. Their resistance to bacteria and staining makes stainless steel trays ideal for commercial dehydrating applications.

Heat Distribution: Performance of Plastic and Stainless Steel Trays

How does heat distribution differ between plastic trays and stainless steel trays when dehydrating? Stainless steel trays provide superior heat conduction, ensuring even drying and preventing hotspots in dehydrated foods. Plastic trays tend to have uneven heat distribution, which can result in inconsistent dehydration and longer drying times.

Food Safety: Chemical Leaching and Hygiene Concerns

| Tray Type | Chemical Leaching Risk | Hygiene Concerns |

|---|---|---|

| Plastic Tray | Higher risk of chemical leaching, especially when exposed to heat during dehydrating, potentially contaminating food with harmful substances like BPA or phthalates. | Porous surface may retain odors and bacteria, requiring thorough and frequent cleaning to prevent contamination and ensure food safety. |

| Stainless Steel Tray | Virtually no chemical leaching, as stainless steel is inert and does not release harmful chemicals even under prolonged heat exposure. | Non-porous, easier to sanitize and maintain, reducing the risk of bacterial growth and cross-contamination during the dehydrating process. |

Durability and Longevity: Which Tray Lasts Longer?

Stainless steel trays offer superior durability compared to plastic trays, resisting warping, cracking, and discoloration during prolonged dehydrating processes. Their corrosion-resistant properties ensure they maintain structural integrity and functionality over years of usage.

Plastic trays, while lighter and more affordable, tend to degrade faster under high heat and repeated exposure to moisture, resulting in shorter lifespan and potential health risks from material breakdown. Investing in stainless steel trays provides long-term reliability and consistent performance for intensive dehydrating tasks.

Ease of Cleaning: Maintenance Comparison

Stainless steel trays offer superior ease of cleaning compared to plastic trays due to their non-porous surface that resists stains and odors. Plastic trays can harbor bacteria in scratches and are more prone to discoloration and warping from heat exposure. Maintenance of stainless steel trays typically requires less effort and ensures longer-lasting hygiene in dehydrating processes.

Flavor and Odor Retention: Impact on Dehydrated Foods

Stainless steel trays excel in preserving the natural flavor and odor of dehydrated foods due to their non-reactive surface, which prevents any metallic taste or unwanted odors from leaching into the food. Plastic trays, especially those made from lower-quality materials, may absorb and retain odors, potentially altering the flavor profile of dehydrated fruits, vegetables, or herbs over time. For optimal flavor retention and to ensure the pure taste of dried foods, stainless steel trays are the preferred choice in dehydration processes.

Cost Analysis: Plastic vs Stainless Steel Investment

Plastic trays for dehydrating generally incur lower upfront costs but may require more frequent replacement due to wear and tear. Stainless steel trays demand a higher initial investment but offer superior durability and long-term savings by resisting corrosion and damage.

- Initial Expense - Plastic trays typically cost 50-70% less than comparable stainless steel trays, making them attractive for budget-conscious buyers.

- Longevity - Stainless steel trays can last over a decade with proper maintenance, whereas plastic trays usually need replacement every 1-3 years.

- Maintenance Costs - Stainless steel's resistance to staining and warping reduces ongoing maintenance expenses compared to plastic counterparts prone to cracking and discoloration.

Environmental Impact: Sustainability Aspects

Stainless steel trays offer superior sustainability due to their durability and recyclability, reducing long-term environmental waste compared to plastic trays. Plastic trays, while lightweight and inexpensive, contribute to pollution and landfill accumulation because they degrade slowly and are often non-recyclable.

- Stainless steel is highly recyclable - It can be melted down and reused indefinitely without losing quality.

- Plastic trays contribute to landfill waste - Many types are not biodegradable and take centuries to break down.

- Durability impacts sustainability - Stainless steel trays last longer, reducing the frequency of replacement and resource consumption.

Related Important Terms

Food-grade plastic leaching

Food-grade plastic trays used for dehydrating may leach harmful chemicals such as phthalates and BPA into food when exposed to heat, affecting food safety and quality. Stainless steel trays offer a non-reactive, durable alternative that prevents chemical contamination while maintaining optimal airflow and heat distribution during dehydration.

Stainless steel mesh airflow

Stainless steel trays with mesh design enhance airflow during dehydrating by allowing hot air to circulate evenly around the food, preventing moisture buildup and ensuring consistent drying. This superior ventilation compared to solid plastic trays reduces drying time and improves overall dehydration efficiency.

BPA-free dehydration trays

Stainless steel trays are BPA-free, non-toxic, and resistant to corrosion, making them a safer and more durable option for dehydrating foods compared to plastic trays that may contain BPA or harmful chemicals. Choosing BPA-free stainless steel trays ensures the preservation of food quality and prevents chemical leaching during the dehydration process.

Heat retention plastic

Plastic trays used for dehydrating offer superior heat retention compared to stainless steel trays, promoting more consistent drying temperatures and energy efficiency. While stainless steel trays conduct heat quickly, their lower insulation properties can lead to uneven drying and longer dehydrating times.

Dishwasher-safe dehydrator trays

Stainless steel trays for dehydrating are dishwasher-safe, offering durability and resistance to staining or odors, making cleanup efficient and hygienic. Plastic trays may be dishwasher-safe but are prone to warping or retaining odors over time, reducing long-term usability compared to stainless steel options.

Off-gassing risk plastic

Stainless steel trays are preferred for dehydrating due to their non-reactive surface, eliminating the risk of off-gassing harmful chemicals that can occur with plastic trays when exposed to heat. Plastic trays may release toxins and microplastics during dehydration, potentially contaminating food and posing health hazards.

Non-reactive stainless tray

Non-reactive stainless steel trays prevent chemical interactions during dehydrating, preserving the purity and flavor of foods better than plastic trays, which may release harmful substances under heat. Stainless steel trays also offer superior durability and heat conductivity, ensuring even dehydration and long-term use without warping or degradation.

Eco-friendly dehydration racks

Stainless steel trays for dehydrating offer superior durability and recyclability, making them an eco-friendly choice compared to plastic trays, which can release harmful chemicals over time and contribute to plastic waste. Stainless steel's resistance to rust and ease of cleaning ensure a longer lifespan, reducing environmental impact and promoting sustainable food dehydration practices.

Plastic tray warping

Plastic trays for dehydrating often warp under high heat, compromising airflow and consistent drying, whereas stainless steel trays maintain structural integrity and ensure even dehydration. The heat resistance and durability of stainless steel make it a superior choice for long-term dehydrating performance compared to susceptible plastic trays.

Plastic tray vs Stainless steel tray for dehydrating. Infographic

cookingdiff.com

cookingdiff.com