Convection drying for fruit leathers relies on hot air circulation to remove moisture, which can result in longer drying times and potential nutrient loss due to prolonged heat exposure. Refractance window drying uses infrared energy transmitted through a transparent surface to rapidly dry fruit leathers, preserving color, flavor, and nutritional content more effectively. This method also offers greater energy efficiency and reduced oxidation compared to convection drying.

Table of Comparison

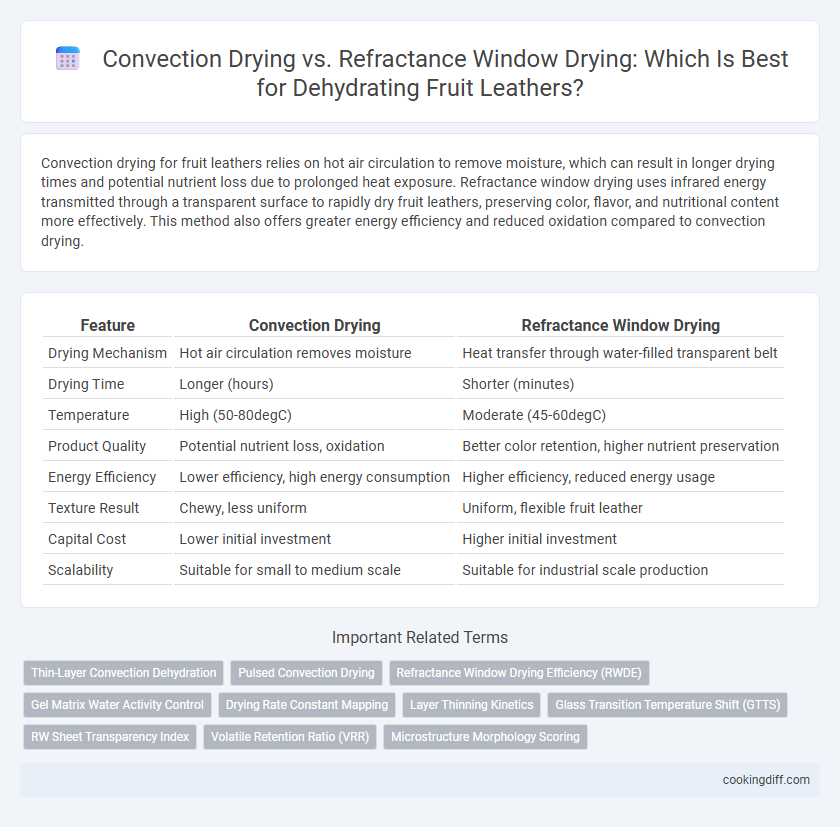

| Feature | Convection Drying | Refractance Window Drying |

|---|---|---|

| Drying Mechanism | Hot air circulation removes moisture | Heat transfer through water-filled transparent belt |

| Drying Time | Longer (hours) | Shorter (minutes) |

| Temperature | High (50-80degC) | Moderate (45-60degC) |

| Product Quality | Potential nutrient loss, oxidation | Better color retention, higher nutrient preservation |

| Energy Efficiency | Lower efficiency, high energy consumption | Higher efficiency, reduced energy usage |

| Texture Result | Chewy, less uniform | Uniform, flexible fruit leather |

| Capital Cost | Lower initial investment | Higher initial investment |

| Scalability | Suitable for small to medium scale | Suitable for industrial scale production |

Overview of Fruit Leather Dehydration Methods

Fruit leather dehydration methods significantly impact texture, flavor retention, and drying efficiency. Convection drying and refractance window drying represent two advanced techniques used to optimize these parameters in fruit leather production.

- Convection Drying - Uses heated air circulation to remove moisture, often resulting in longer drying times and potential nutrient loss.

- Refractance Window Drying - Employs a transparent conveyor belt over hot water, enabling rapid drying with better preservation of color and bioactive compounds.

- Energy Efficiency - Refractance window drying generally consumes less energy compared to convection drying due to faster moisture removal.

Choosing the appropriate dehydration method depends on desired product quality and processing costs.

Introduction to Convection Drying Technology

Convection drying technology utilizes hot air circulation to remove moisture from fruit leathers efficiently, ensuring even drying and preservation of texture. This method is widely adopted due to its simplicity and cost-effectiveness in industrial-scale fruit leather production. Unlike Refractance Window drying, convection drying may require longer processing times and can affect heat-sensitive nutrients.

What Is Refractance Window Drying?

Refractance Window Drying (RWD) is an innovative dehydration technique that uses a transparent plastic conveyor belt over hot water to dry fruit leathers quickly and efficiently. This method preserves the color, flavor, and nutritional content better than convection drying by reducing exposure to high heat and oxygen. RWD offers uniform drying, lower energy consumption, and a shorter processing time compared to traditional convection drying methods.

Energy Efficiency: Convection vs Refractance Window Drying

Convection drying of fruit leathers typically consumes higher energy due to prolonged exposure to hot air, leading to increased operational costs and carbon footprint. Refractance window drying offers superior energy efficiency by using low-temperature water heat transfer, significantly reducing drying time and energy consumption.

Refractance window drying maintains nutritional quality while minimizing energy use compared to convection drying methods. The process achieves uniform drying at lower temperatures, preserving antioxidants and vitamins in fruit leathers. This method reduces overall energy demand by up to 50% compared to conventional convection drying techniques.

Impact on Nutrient Retention in Fruit Leathers

Convection drying often leads to significant nutrient loss in fruit leathers due to prolonged exposure to high temperatures and oxygen. Refractance window drying preserves more vitamins and antioxidants by utilizing lower temperatures and shorter drying times.

- Vitamin retention - Refractance window drying maintains up to 80% of vitamin C, compared to less than 50% in convection drying.

- Antioxidant preservation - The gentle heat of refractance window drying protects polyphenols better than the oxidative conditions in convection drying.

- Texture and flavor impact - Reduced drying time in refractance window drying minimizes nutrient degradation and helps retain the natural flavor and texture of fruit leathers.

Texture and Sensory Quality Comparison

Convection drying typically results in a firmer texture with a slight toughness in fruit leathers due to slower moisture removal, which can affect chewiness and overall mouthfeel. This method often leads to a less vibrant color and a reduced retention of volatile aroma compounds, impacting sensory appeal.

Refractance window drying preserves a softer, more pliable texture in fruit leathers by rapidly removing moisture at lower temperatures, enhancing tenderness and flexibility. It better retains natural colors and flavors, resulting in superior sensory quality with enhanced aroma and taste profiles.

Drying Time and Process Optimization

| Convection drying of fruit leathers typically requires 4-6 hours at 60-70degC, resulting in moderate energy consumption and uniform moisture removal. Refractance window drying significantly reduces drying time to 20-40 minutes by directly transferring heat through a thin water film, optimizing processing efficiency. Process optimization in refractance drying yields higher retention of flavor and nutrients due to rapid dehydration and controlled temperature exposure compared to convection drying. |

Cost Analysis of Both Drying Methods

Convection drying of fruit leathers involves higher energy consumption and longer drying times, leading to increased operational costs compared to refractance window drying. Equipment costs for convection dryers are generally lower, but the extended drying process raises labor and utility expenses significantly.

Refractance window drying offers faster drying rates and lower energy usage, reducing overall production costs despite higher initial equipment investment. This method minimizes product loss and enhances yield, improving cost-efficiency for large-scale fruit leather production.

Scalability for Industrial and Home Production

Convection drying offers scalable solutions suitable for both industrial and home production of fruit leathers due to its well-established technology and ease of control. Refractance window drying, while more energy-efficient and faster, currently faces limitations in large-scale industrial deployment but excels in small-batch, artisanal settings.

- Convection drying scalability - Widely adopted in industry with equipment ranging from small household units to large industrial dryers.

- Refractance window drying efficiency - Provides rapid drying with higher nutrient retention, ideal for premium fruit leather products in home or boutique production.

- Industrial challenges - Refractance window drying requires specialized equipment and infrastructure, limiting its current use in mass production.

Related Important Terms

Thin-Layer Convection Dehydration

Thin-layer convection drying of fruit leathers involves circulating hot air to remove moisture efficiently, offering uniform drying but often requiring longer processing times and higher energy consumption compared to refractance window drying. Refractance window drying uses infrared energy transmitted through a thin plastic sheet to rapidly dehydrate fruit leathers while preserving color, flavor, and nutritional quality more effectively than traditional convection methods.

Pulsed Convection Drying

Pulsed convection drying enhances moisture removal efficiency in fruit leathers by intermittently cycling hot air, reducing thermal degradation compared to continuous convection methods. Unlike refractance window drying, pulsed convection offers improved control over drying kinetics, resulting in better texture retention and nutrient preservation in the final product.

Refractance Window Drying Efficiency (RWDE)

Refractance Window Drying (RWD) demonstrates superior RWDE by preserving higher nutrient retention and achieving faster drying rates compared to conventional convection drying for fruit leathers. Its ability to utilize low-temperature, transparent thermal conduction through a thin film significantly reduces drying time while maintaining product quality and texture.

Gel Matrix Water Activity Control

Convection drying reduces water activity in fruit leathers by promoting gel matrix dehydration through heated air circulation, but often results in uneven moisture removal and longer drying times. Refractance window drying efficiently controls water activity by rapidly evaporating surface moisture with minimal heat exposure, preserving the gel matrix integrity and enhancing shelf stability.

Drying Rate Constant Mapping

Convection drying exhibits a lower drying rate constant compared to refractance window drying, indicating slower moisture removal in fruit leathers. Refractance window drying accelerates dehydration by enhancing heat transfer through direct contact with the heated transparent membrane, leading to higher drying rate constants and improved product quality.

Layer Thinning Kinetics

Convection drying of fruit leathers exhibits slower layer thinning kinetics due to limited heat transfer efficiency, resulting in prolonged drying times and potential quality degradation. Refractance window drying enhances layer thinning rates by utilizing direct infrared energy transfer through a transparent medium, accelerating moisture removal while preserving sensory and nutritional qualities.

Glass Transition Temperature Shift (GTTS)

Convection drying of fruit leathers often induces a higher Glass Transition Temperature Shift (GTTS), leading to increased molecular mobility and potential texture degradation; in contrast, Refractance Window drying minimizes GTTS by rapidly removing moisture at lower temperatures, preserving the fruit leather's structural integrity and sensory properties. Optimizing drying parameters through Refractance Window technology effectively maintains the desirable glassy state, enhancing shelf life and preventing brittleness compared to conventional convection methods.

RW Sheet Transparency Index

Refractance window (RW) drying outperforms convection drying for fruit leathers by preserving higher nutrient retention and color quality due to its unique heat transfer through a transparent Mylar sheet, quantified by the RW Sheet Transparency Index. A higher RW Sheet Transparency Index directly enhances drying efficiency and product quality by optimizing solar energy transmission and minimizing thermal degradation in fruit leathers.

Volatile Retention Ratio (VRR)

Convection drying of fruit leathers generally results in lower Volatile Retention Ratio (VRR) due to prolonged exposure to high temperatures, leading to significant loss of aroma and flavor compounds. Refractance window drying maintains a higher VRR by employing rapid heat transfer at lower temperatures, preserving more volatile compounds crucial for the sensory quality of fruit leathers.

Convection drying vs Refractance window drying for fruit leathers. Infographic

cookingdiff.com

cookingdiff.com