Dehydrators use low heat and airflow to remove moisture from food, preserving flavor and nutrients while reducing weight and volume. Freeze drying machines freeze food and then use a vacuum to remove ice through sublimation, retaining texture, color, and nutrients more effectively for long-term storage. Choosing between a dehydrator and a freeze drying machine depends on factors like budget, preservation duration, and desired food quality.

Table of Comparison

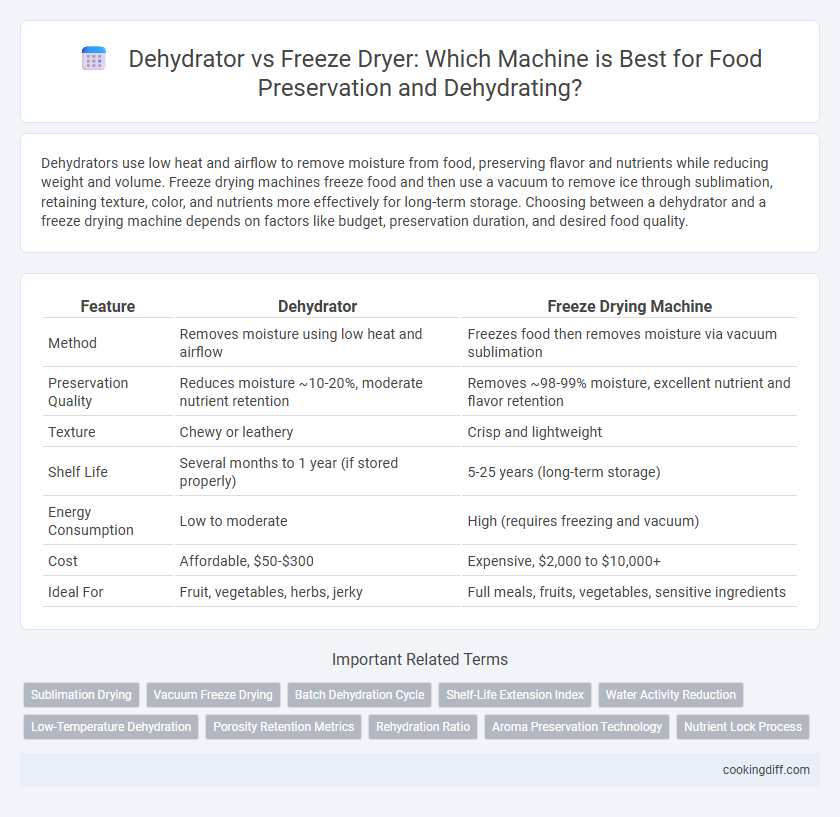

| Feature | Dehydrator | Freeze Drying Machine |

|---|---|---|

| Method | Removes moisture using low heat and airflow | Freezes food then removes moisture via vacuum sublimation |

| Preservation Quality | Reduces moisture ~10-20%, moderate nutrient retention | Removes ~98-99% moisture, excellent nutrient and flavor retention |

| Texture | Chewy or leathery | Crisp and lightweight |

| Shelf Life | Several months to 1 year (if stored properly) | 5-25 years (long-term storage) |

| Energy Consumption | Low to moderate | High (requires freezing and vacuum) |

| Cost | Affordable, $50-$300 | Expensive, $2,000 to $10,000+ |

| Ideal For | Fruit, vegetables, herbs, jerky | Full meals, fruits, vegetables, sensitive ingredients |

Introduction to Food Preservation Methods

Food preservation methods such as dehydrating and freeze drying extend shelf life by removing moisture from food, preventing microbial growth and spoilage. Both techniques retain nutritional value differently, influencing texture and flavor retention in preserved items.

- Dehydrator - Utilizes controlled heat and airflow to evaporate water content from food, producing a chewy or leathery texture.

- Freeze Drying Machine - Removes moisture through sublimation by freezing food and reducing surrounding pressure, preserving texture and nutrients more effectively.

- Application - Dehydrators are cost-effective and suitable for common household use, whereas freeze drying machines are more complex and ideal for long-term storage and specialty foods.

Choosing between a dehydrator and freeze drying machine depends on preservation goals, budget, and desired food quality outcomes.

How Dehydrators Work: Process and Benefits

Dehydrators preserve food by removing moisture through low heat and consistent airflow, effectively inhibiting microbial growth and enzymatic activity. This process maintains the food's flavor, nutrients, and texture while extending its shelf life significantly.

Proper dehydration reduces weight and volume, making storage and transportation easier and more cost-effective. Unlike freeze drying, dehydrators use less energy and equipment, providing an affordable option for long-term food preservation.

Understanding Freeze Drying Machines

Freeze drying machines preserve food by removing moisture through sublimation, which retains nutritional value and flavor better than traditional dehydrators. These machines are ideal for long-term storage and maintaining the original texture of food.

- Sublimation Process - Freeze drying removes water by turning ice directly into vapor, preserving food structure.

- Long-Term Storage - Freeze dried foods can last for years without refrigeration, making them suitable for emergency supplies.

- Higher Nutrient Retention - This method retains more nutrients compared to conventional dehydrating techniques.

Nutritional Impact: Dehydrating vs Freeze Drying

Dehydrators remove moisture from food by applying low heat over extended periods, causing some loss of heat-sensitive nutrients such as vitamins C and B complex. Freeze drying machines preserve nutritional content more effectively by sublimating ice directly into vapor under low temperatures, retaining up to 97% of vitamins and antioxidants.

While both methods extend shelf life and reduce spoilage, freeze drying offers superior nutrient retention and better maintains flavor and texture. Dehydration can lead to nutrient degradation and changes in food structure due to prolonged heat exposure. Freeze drying, albeit more expensive, remains the preferred choice for preserving delicate nutrients in fruits, vegetables, and herbs.

Texture and Flavor Differences

Dehydrators remove moisture through low heat and airflow, preserving a chewy texture and intensified flavor in foods. Freeze drying machines use sublimation to remove moisture, maintaining a light, crispy texture and more natural flavor retention. Foods processed by freeze drying typically rehydrate better, preserving original taste and nutrients more effectively than dehydrated products.

Storage Life and Shelf Stability Comparison

Dehydrators reduce moisture in food to around 10-20%, extending shelf life to several months under proper storage conditions. Freeze drying machines remove nearly 98-99% of moisture, resulting in shelf stability that can last several years without refrigeration. Freeze dried foods maintain more nutrients and texture, offering superior long-term preservation compared to dehydrated foods.

Energy Efficiency and Cost Considerations

Dehydrators generally consume less energy than freeze drying machines, making them more cost-effective for long-term food preservation. Freeze drying machines, while more expensive upfront and in energy use, preserve nutritional content and flavor more effectively.

- Energy consumption - Dehydrators use lower wattage and shorter run times compared to energy-intensive freeze drying machines.

- Initial cost - Freeze drying equipment has significantly higher purchase costs than most dehydrators.

- Operational cost - Freeze drying requires continuous energy input for vacuum and freezing functions, increasing electricity bills.

Space and Equipment Requirements

How do space and equipment requirements differ between dehydrators and freeze drying machines for food preservation? Dehydrators typically require less space and simpler equipment, making them suitable for home kitchens or small-scale use. Freeze drying machines demand larger, specialized equipment and more space due to their complex vacuum and freezing systems essential for preserving food quality.

Ideal Foods for Each Preservation Method

| Dehydrator | Freeze Drying Machine |

|---|---|

| Ideal for drying fruits like apples, bananas, and berries, vegetables such as tomatoes and peppers, and herbs that benefit from moisture removal while retaining flavor. | Perfect for preserving delicate foods like strawberries, mushrooms, and cooked meals that require maintaining shape, texture, and nutrient retention over long-term storage. |

| Works best with high-sugar or high-acid foods, allowing safe curing and extended shelf-life without refrigeration. | Suitable for complex dishes and dairy products, as it removes water through sublimation, preserving cell structure and rehydration quality. |

Related Important Terms

Sublimation Drying

Sublimation drying, employed in freeze drying machines, removes moisture from food by transitioning ice directly into vapor, preserving flavor, texture, and nutrients more effectively than dehydrators that use evaporative heat. Freeze drying machines maintain superior food quality and shelf life but require higher energy consumption and cost compared to traditional dehydrators.

Vacuum Freeze Drying

Vacuum freeze drying machines preserve food by removing moisture through sublimation under low temperature and vacuum, maintaining nutritional content, flavor, and texture better than conventional dehydrators. This advanced process extends shelf life without refrigeration and is ideal for delicate foods requiring minimal nutrient loss.

Batch Dehydration Cycle

Batch dehydration cycles in dehydrators typically last 6 to 12 hours at temperatures between 125degF and 160degF, efficiently removing moisture through controlled heat and air circulation to inhibit bacterial growth. Freeze drying machines use low pressure and subzero temperatures over 20 to 48 hours, preserving food texture and nutrients by sublimating ice directly into vapor without thawing, but require significantly longer processing times per batch.

Shelf-Life Extension Index

Dehydrators typically extend food shelf-life by reducing moisture content to around 10-20%, resulting in a shelf-life extension index of up to 6-12 months under proper storage conditions. Freeze drying machines remove nearly 98-99% of moisture through sublimation, achieving a shelf-life extension index exceeding 25 years while preserving nutritional content and flavor integrity.

Water Activity Reduction

Dehydrators reduce water activity by evaporating moisture through low heat, effectively lowering the water content to extend shelf life and inhibit microbial growth. Freeze drying machines remove water by sublimation under low pressure and temperature, achieving an even lower water activity level that preserves food texture and nutrients more efficiently than conventional dehydration.

Low-Temperature Dehydration

Low-temperature dehydration in food preservation maintains nutritional value and flavor by drying at temperatures below 140degF, unlike traditional dehydrators that may use higher heat and risk nutrient loss. Freeze drying machines use sublimation at extremely low temperatures, preserving texture and nutrients more effectively but at higher cost and complexity compared to economical low-temperature dehydrators.

Porosity Retention Metrics

Dehydrators typically reduce moisture content by evaporation, leading to a denser product with lower porosity retention, whereas freeze drying machines preserve food structure by sublimating ice directly, resulting in significantly higher porosity metrics often above 80%. This enhanced porosity in freeze-dried foods enables better rehydration and retention of texture compared to dehydrated products, which usually exhibit porosity retention below 50%.

Rehydration Ratio

Dehydrators typically achieve a rehydration ratio between 3:1 and 5:1, indicating moderate moisture absorption during food restoration, while freeze drying machines often reach ratios above 8:1, preserving cellular structure for superior water uptake. Higher rehydration ratios in freeze-dried foods contribute to better texture, flavor retention, and overall food quality compared to dehydrated products.

Aroma Preservation Technology

Dehydrators use low heat to remove moisture from food, which can slightly alter the aroma compounds due to slow evaporation, whereas freeze drying machines employ sublimation under low temperatures to preserve food aroma more effectively by maintaining volatile compounds intact. Freeze drying technology excels at retaining the original aroma profile of fruits, herbs, and meats, making it a superior choice for preserving the sensory qualities of food.

Dehydrator vs Freeze Drying Machine for Food Preservation Infographic

cookingdiff.com

cookingdiff.com