Rotary dehydrators provide consistent drying by continuously tumbling products, making them ideal for delicate items and ensuring uniform moisture removal in bulk processing. Vertical dehydrators maximize space efficiency with a stationary design that promotes airflow through stacked trays, which suits larger batches of dense or uniform products. Selecting between rotary and vertical dehydrators depends on product type, drying uniformity requirements, and available processing space.

Table of Comparison

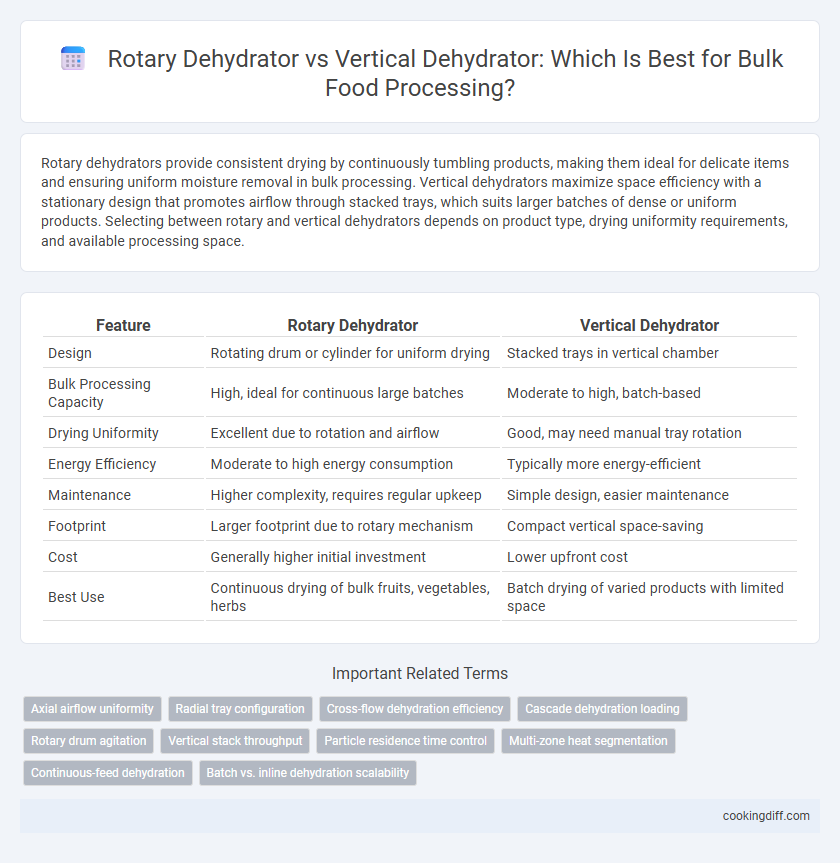

| Feature | Rotary Dehydrator | Vertical Dehydrator |

|---|---|---|

| Design | Rotating drum or cylinder for uniform drying | Stacked trays in vertical chamber |

| Bulk Processing Capacity | High, ideal for continuous large batches | Moderate to high, batch-based |

| Drying Uniformity | Excellent due to rotation and airflow | Good, may need manual tray rotation |

| Energy Efficiency | Moderate to high energy consumption | Typically more energy-efficient |

| Maintenance | Higher complexity, requires regular upkeep | Simple design, easier maintenance |

| Footprint | Larger footprint due to rotary mechanism | Compact vertical space-saving |

| Cost | Generally higher initial investment | Lower upfront cost |

| Best Use | Continuous drying of bulk fruits, vegetables, herbs | Batch drying of varied products with limited space |

Overview of Rotary and Vertical Dehydrators

Rotary dehydrators feature a rotating drum that ensures even drying by continuously tumbling the product, ideal for bulk processing of small, uniform items. Vertical dehydrators use stacked trays with a vertical air flow system, optimizing space and allowing simultaneous drying of large quantities with consistent temperature control.

Both systems enhance dehydration efficiency but differ in design focus: rotary models excel in uniformity and gentle handling, while vertical dehydrators prioritize capacity and ease of loading. Choosing between them depends on product type, drying time, and production scale in industrial dehydration applications.

Core Operating Principles: Rotary vs Vertical Designs

Rotary dehydrators utilize a rotating drum to ensure even exposure of materials to heated air, promoting uniform drying. Vertical dehydrators rely on stacked trays with hot air rising through natural or forced convection for batch processing.

- Rotary drum rotation - Continuously mixes product to prevent clumping and improve drying consistency.

- Vertical tray stacking - Maximizes space efficiency with a compact footprint for large batch volumes.

- Airflow direction - Rotary designs often use radial airflow, while vertical dehydrators employ upward airflow through trays.

Choosing between rotary and vertical designs depends on material type, batch size, and desired drying uniformity.

Capacity Comparison for Bulk Food Processing

Rotary dehydrators offer higher capacity for bulk food processing due to their continuous rotation mechanism, which ensures even drying and maximizes throughput. Vertical dehydrators generally have smaller trays stacked vertically, limiting their capacity in large-scale operations.

Rotary dehydrators can process several hundred pounds per batch, making them ideal for commercial use and large food production facilities. Vertical dehydrators are more suitable for small to medium batches, with capacities ranging from 20 to 100 pounds per cycle. Capacity efficiency in rotary models often translates to faster processing times and lower labor costs in bulk dehydrating scenarios.

Efficiency and Drying Time Differences

| Dehydrator Type | Efficiency | Drying Time |

|---|---|---|

| Rotary Dehydrator | Offers uniform drying through continuous rotation, enhancing airflow and minimizing hot spots for consistent bulk processing results. | Typically reduces drying time by 20-30% compared to vertical models due to improved heat distribution and constant material movement. |

| Vertical Dehydrator | Features stacked trays that may cause uneven airflow, leading to variable moisture levels across product batches. | Requires longer drying times as static trays limit heat penetration and airflow efficiency, often extending bulk processing cycles. |

Uniformity of Dehydration: Performance Analysis

Rotary dehydrators provide superior uniformity in bulk processing due to continuous rotation, which ensures even exposure to heat and airflow. Vertical dehydrators may suffer from uneven dehydration as trays on different levels experience varying airflow and temperature conditions.

- Rotary Motion Enhances Uniformity - Continuous rotation prevents localized drying or moisture retention on specific trays.

- Vertical Design Faces Airflow Limitations - Static trays in vertical dehydrators often result in inconsistent drying across layers.

- Efficiency in Large Volumes - Rotary dehydrators maintain consistent dehydration quality when processing large quantities of product.

Energy Consumption and Cost Implications

Rotary dehydrators typically consume more energy due to their rotating trays, which require continuous motor operation, leading to higher operational costs in bulk processing. Vertical dehydrators, with stationary trays and natural air circulation, tend to be more energy-efficient and cost-effective over long-term use.

- Energy Consumption - Rotary dehydrators use electric motors for rotation, increasing power usage compared to static vertical designs.

- Operational Cost - Elevated energy demand in rotary models results in higher electricity bills during extended bulk dehydration cycles.

- Maintenance Expenses - Rotary dehydrators often incur greater maintenance costs due to moving parts, unlike simpler vertical units with fewer mechanical components.

Maintenance and Cleaning Considerations

Which type of dehydrator requires less maintenance and easier cleaning for bulk processing? Rotary dehydrators often demand more frequent maintenance due to moving parts and complex mechanisms, increasing downtime. Vertical dehydrators feature simpler construction, making cleaning and upkeep more straightforward and efficient for continuous large-scale use.

Suitability for Various Food Types

Rotary dehydrators offer uniform drying and are highly suitable for small to medium-sized batches of thinly sliced fruits, vegetables, and herbs, ensuring consistent moisture removal. Vertical dehydrators excel in handling large quantities of bulkier items like meat and nuts, providing efficient airflow and uniform heat distribution across multiple trays. Selecting between rotary and vertical dehydrators depends on the specific food type and volume, with rotary preferred for delicate, thin products and vertical ideal for dense, heavy items in bulk processing.

Industrial Applications: Best Use Cases

Rotary dehydrators excel in industrial applications requiring uniform drying of bulky, irregularly shaped products such as fruits and vegetables, leveraging continuous rotation for even heat distribution. Their design supports high-capacity throughput with consistent moisture reduction, ideal for large-scale food processing facilities.

Vertical dehydrators are better suited for granular or small-size products like grains and powders due to their efficient airflow and compact footprint. They offer precise temperature control and energy efficiency, making them optimal for industries focused on dehydrating pharmaceuticals and fine chemicals.

Related Important Terms

Axial airflow uniformity

Rotary dehydrators provide superior axial airflow uniformity by continuously rotating the product trays, ensuring even exposure to heat and consistent drying in bulk processing. Vertical dehydrators often suffer from uneven airflow distribution, leading to hotspots and variable moisture content across batches.

Radial tray configuration

Rotary dehydrators with radial tray configurations provide uniform airflow and consistent drying for bulk processing, improving product quality and throughput. Vertical dehydrators typically have stacked trays that may limit airflow distribution, resulting in less efficient moisture removal and longer drying times.

Cross-flow dehydration efficiency

Rotary dehydrators utilize continuous rotation to enhance cross-flow dehydration efficiency by exposing product evenly to hot air, resulting in faster moisture removal and consistent drying for bulk processing. Vertical dehydrators rely on static trays stacked vertically, where cross-flow airflow is less uniform, often leading to longer drying times and reduced efficiency in large-scale operations.

Cascade dehydration loading

Rotary dehydrators offer uniform drying by rotating trays, ideal for bulk processing with cascade dehydration loading that enhances air distribution and moisture evaporation. Vertical dehydrators, while space-efficient, may have uneven drying and slower processing times due to stacked trays that limit airflow in cascade loading configurations.

Rotary drum agitation

Rotary dehydrators with drum agitation enhance bulk processing by ensuring uniform drying and preventing product clumping through continuous tumbling, which improves heat and mass transfer efficiency compared to static vertical dehydrators. Vertical dehydrators offer space-saving advantages but may lead to uneven drying and increased risk of product degradation due to limited agitation during bulk dehydration.

Vertical stack throughput

Vertical dehydrators with stacked trays maximize bulk processing throughput by enabling simultaneous large-batch drying in a compact footprint, outperforming rotary dehydrators which offer slower, less efficient drying due to their rotating mechanism. High-capacity vertical stack designs ensure uniform airflow distribution and faster moisture removal, making them ideal for industrial-scale dehydration operations.

Particle residence time control

Rotary dehydrators offer superior particle residence time control through continuous rotation, ensuring uniform drying and preventing material clumping in bulk processing. Vertical dehydrators have fixed particle trajectories, leading to less precise residence time management and potential variability in moisture content.

Multi-zone heat segmentation

Rotary dehydrators offer multi-zone heat segmentation that enables precise temperature control across different drum sections, enhancing uniform drying for bulk processing. Vertical dehydrators typically provide less distinct heat zones, resulting in slower moisture removal and less consistent product quality in large-scale dehydration.

Continuous-feed dehydration

Rotary dehydrators ensure uniform drying by continuously tumbling product in bulk, optimizing heat and airflow for consistent moisture removal in continuous-feed dehydration processes. Vertical dehydrators enable space-efficient stacking and easy product loading but may face challenges with uneven drying and airflow distribution during high-volume, continuous operations.

Rotary dehydrator vs Vertical dehydrator for bulk processing Infographic

cookingdiff.com

cookingdiff.com