Vacuum dehydrators preserve the nutritional value and flavor of pet food more effectively by removing moisture at lower temperatures compared to traditional dehydrators, which use higher heat and longer drying times. The gentle dehydration process in vacuum dehydrators reduces nutrient loss and prevents oxidation, making them ideal for maintaining the quality of sensitive ingredients. In contrast, traditional dehydrators may lead to uneven drying and diminished nutrient retention, affecting the overall health benefits of dehydrated pet treats.

Table of Comparison

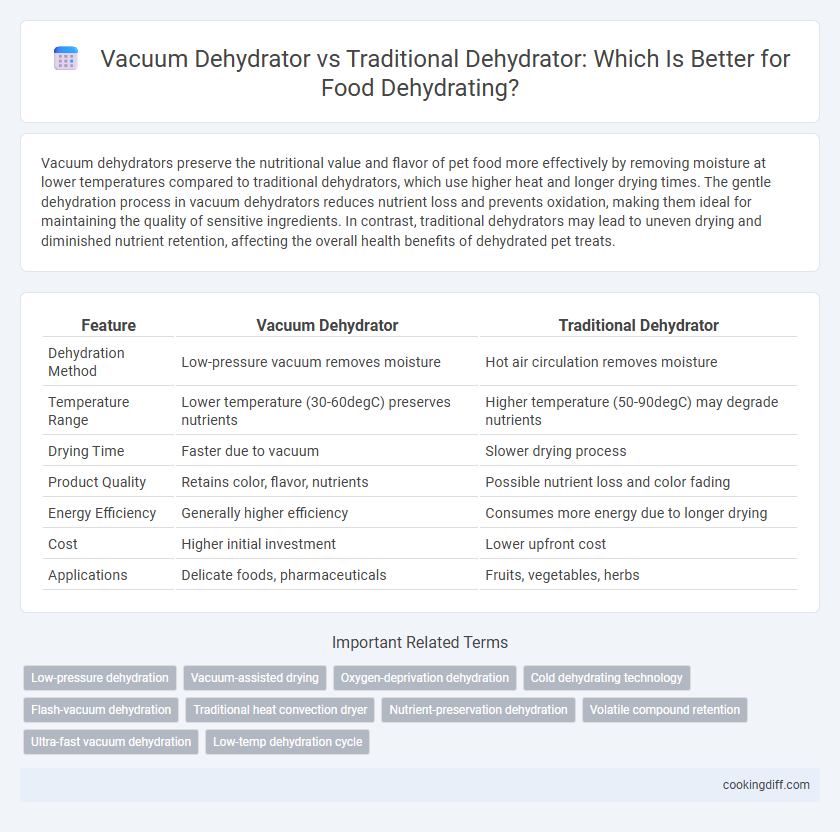

| Feature | Vacuum Dehydrator | Traditional Dehydrator |

|---|---|---|

| Dehydration Method | Low-pressure vacuum removes moisture | Hot air circulation removes moisture |

| Temperature Range | Lower temperature (30-60degC) preserves nutrients | Higher temperature (50-90degC) may degrade nutrients |

| Drying Time | Faster due to vacuum | Slower drying process |

| Product Quality | Retains color, flavor, nutrients | Possible nutrient loss and color fading |

| Energy Efficiency | Generally higher efficiency | Consumes more energy due to longer drying |

| Cost | Higher initial investment | Lower upfront cost |

| Applications | Delicate foods, pharmaceuticals | Fruits, vegetables, herbs |

Introduction to Food Dehydration

What are the differences between vacuum dehydrators and traditional dehydrators in food dehydration? Vacuum dehydrators remove moisture at lower temperatures by creating a vacuum environment, which helps preserve nutrients and flavor more effectively. Traditional dehydrators use heat and air circulation, which can be less efficient and may cause some nutrient loss during the drying process.

What is a Vacuum Dehydrator?

A vacuum dehydrator removes moisture from food by lowering the pressure around it, enabling dehydration at lower temperatures and preserving nutritional quality. This method reduces oxidation and enzymatic reactions, resulting in better flavor retention and color compared to traditional dehydrators. Vacuum dehydrators are especially effective for heat-sensitive foods and pharmaceuticals, ensuring longer shelf life and enhanced product integrity.

What is a Traditional Dehydrator?

A traditional dehydrator uses heated air circulation to remove moisture from food, relying on a built-in fan and heating element to maintain consistent drying temperatures. It operates at temperatures typically ranging from 95degF to 160degF, suitable for drying fruits, vegetables, and herbs.

These dehydrators are widely available and often more affordable, providing straightforward control over temperature settings and drying time. They do not create a vacuum environment, so the drying process can take longer compared to vacuum dehydrators and may result in some nutrient loss due to exposure to oxygen and heat.

Key Differences: Vacuum vs Traditional Dehydrators

Vacuum dehydrators operate under reduced pressure, which lowers the boiling point of water and enables dehydration at lower temperatures, preserving nutrients and flavors better than traditional dehydrators. Traditional dehydrators use higher temperatures and atmospheric pressure, often resulting in longer drying times and potential nutrient loss.

- Operating Pressure - Vacuum dehydrators function under low pressure, while traditional dehydrators operate at atmospheric pressure.

- Temperature Control - Vacuum methods allow drying at lower temperatures, reducing thermal damage compared to high temperatures in traditional dehydrators.

- Drying Efficiency - Vacuum dehydrators typically dry products faster and maintain better color and nutritional quality than traditional methods.

Efficiency and Dehydration Speed Comparison

Vacuum dehydrators significantly enhance efficiency by operating at lower temperatures, preserving nutrients while reducing energy consumption. Their dehydration speed outperforms traditional dehydrators due to the vacuum environment accelerating moisture removal.

- Energy Efficiency - Vacuum dehydrators consume up to 30% less energy compared to traditional hot-air dehydrators.

- Dehydration Temperature - Operating at 40-60degC, vacuum dehydrators prevent nutrient loss unlike traditional units that require 60-85degC.

- Drying Time - Vacuum technology can reduce dehydration time by 20-50% versus conventional methods.

Nutrient and Flavor Retention Analysis

Vacuum dehydrators operate under reduced pressure and lower temperatures, significantly preserving heat-sensitive nutrients such as vitamins C and B-complex, which are often degraded in traditional dehydrators. This method also retains volatile flavor compounds by minimizing oxidation and thermal breakdown, resulting in superior taste profiles.

Traditional dehydrators use higher temperatures and normal atmospheric pressure, leading to greater nutrient loss and diminished flavor intensity due to prolonged exposure to oxygen and heat. Comparative studies indicate vacuum dehydration can retain up to 40% more antioxidants and essential oils compared to conventional drying techniques.

Energy Consumption: Which is More Efficient?

Vacuum dehydrators consume significantly less energy compared to traditional dehydrators due to their lower drying temperatures and faster moisture removal rates. This efficiency translates into reduced operational costs and a smaller environmental footprint during food dehydration processes.

- Lower Temperature Requirement - Vacuum dehydrators operate at lower temperatures, reducing energy needed for heating.

- Faster Drying Times - Accelerated moisture evaporation shortens cycle duration, saving electricity.

- Energy Cost Savings - Efficient energy use leads to decreased utility bills over extended use.

Choosing vacuum dehydration is a more sustainable option for energy-conscious food processing.

Cost Comparison: Investment and Maintenance

Vacuum dehydrators generally require a higher initial investment compared to traditional dehydrators due to advanced technology and specialized components. Maintenance costs for vacuum dehydrators tend to be more expensive because of the need for periodic calibration and vacuum pump servicing. Traditional dehydrators have lower upfront and upkeep costs, making them more accessible for small-scale operations but potentially less efficient in preserving product quality.

Suitability for Different Foods and Use Cases

| Vacuum Dehydrator | Ideal for heat-sensitive foods like fruits, vegetables, and herbs due to low-temperature drying preserving nutrients and flavor. Suitable for delicate items requiring uniform moisture removal without oxidation. Commonly used in pharmaceutical and specialty food industries for high-quality preservation. |

| Traditional Dehydrator | Best for sturdy foods such as meats, nuts, and thicker fruits that tolerate higher temperatures. Works well for general home use where rapid drying is prioritized over nutrient retention. Suitable for large batches and versatile food varieties with standard moisture levels. |

Related Important Terms

Low-pressure dehydration

Vacuum dehydrators utilize low-pressure environments to lower the boiling point of water, enabling faster and more efficient dehydration at lower temperatures, which preserves nutritional content and flavor better than traditional dehydrators. Traditional dehydrators rely on ambient pressure and higher heat, resulting in longer drying times and potential degradation of heat-sensitive compounds during dehydration.

Vacuum-assisted drying

Vacuum-assisted drying in vacuum dehydrators reduces the boiling point of water, enabling faster moisture removal at lower temperatures and preserving heat-sensitive nutrients and flavors more effectively than traditional dehydrators. This method improves energy efficiency and product quality by minimizing oxidation and enzymatic degradation during the dehydration process.

Oxygen-deprivation dehydration

Vacuum dehydrators remove oxygen from the environment, significantly reducing oxidation and preserving the nutritional quality and color of food compared to traditional dehydrators that rely on hot air and expose food to oxygen. Oxygen-deprivation dehydration in vacuum systems enhances shelf life and flavor retention by minimizing enzymatic and oxidative reactions during the drying process.

Cold dehydrating technology

Vacuum dehydrators utilize cold dehydrating technology by lowering the pressure to remove moisture at reduced temperatures, preserving heat-sensitive nutrients and flavors better than traditional dehydrators that rely on heat to evaporate water. This method minimizes thermal damage and enhances retention of color, aroma, and nutritional value in dehydrated products, making vacuum dehydration ideal for delicate food items.

Flash-vacuum dehydration

Flash-vacuum dehydration uses rapid pressure reduction combined with controlled heat to remove moisture instantly, preserving more nutrients and color compared to traditional dehydrators that rely on prolonged heat exposure. Vacuum dehydrators reduce oxidation and enzymatic reactions, enhancing shelf life and flavor retention in fruits and vegetables.

Traditional heat convection dryer

Traditional heat convection dryers use hot air circulation to remove moisture from food, providing an affordable and straightforward dehydration method ideal for home use. These dryers rely on consistent temperature control and airflow but typically require longer drying times compared to vacuum dehydrators, which operate under low pressure to speed up dehydration while preserving nutrients and flavor.

Nutrient-preservation dehydration

Vacuum dehydrators operate at lower temperatures and reduced pressure, significantly minimizing nutrient degradation compared to traditional dehydrators that use higher heat and longer drying times. This controlled environment in vacuum dehydration preserves heat-sensitive vitamins and antioxidants more effectively, ensuring higher nutritional retention in dried foods.

Volatile compound retention

Vacuum dehydrators preserve volatile compounds more effectively than traditional dehydrators due to their low-pressure environment, which reduces oxidation and thermal degradation during drying. This method maintains the aroma and flavor profile of sensitive foods, making it ideal for herbs and spices requiring high-quality retention.

Ultra-fast vacuum dehydration

Ultra-fast vacuum dehydration reduces drying time by up to 70% compared to traditional dehydrators, preserving nutrients and flavor through low-temperature processing. Vacuum dehydrators maintain a controlled low-pressure environment that prevents oxidation and thermal damage, resulting in higher-quality dehydrated products.

Vacuum dehydrator vs Traditional dehydrator for dehydrating. Infographic

cookingdiff.com

cookingdiff.com