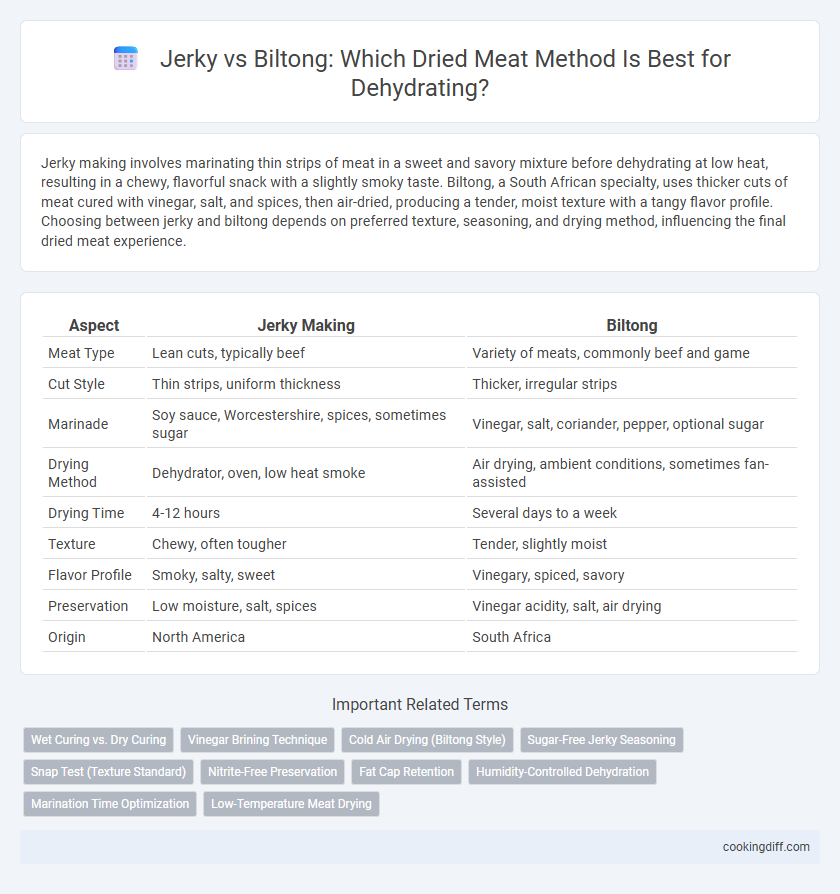

Jerky making involves marinating thin strips of meat in a sweet and savory mixture before dehydrating at low heat, resulting in a chewy, flavorful snack with a slightly smoky taste. Biltong, a South African specialty, uses thicker cuts of meat cured with vinegar, salt, and spices, then air-dried, producing a tender, moist texture with a tangy flavor profile. Choosing between jerky and biltong depends on preferred texture, seasoning, and drying method, influencing the final dried meat experience.

Table of Comparison

| Aspect | Jerky Making | Biltong |

|---|---|---|

| Meat Type | Lean cuts, typically beef | Variety of meats, commonly beef and game |

| Cut Style | Thin strips, uniform thickness | Thicker, irregular strips |

| Marinade | Soy sauce, Worcestershire, spices, sometimes sugar | Vinegar, salt, coriander, pepper, optional sugar |

| Drying Method | Dehydrator, oven, low heat smoke | Air drying, ambient conditions, sometimes fan-assisted |

| Drying Time | 4-12 hours | Several days to a week |

| Texture | Chewy, often tougher | Tender, slightly moist |

| Flavor Profile | Smoky, salty, sweet | Vinegary, spiced, savory |

| Preservation | Low moisture, salt, spices | Vinegar acidity, salt, air drying |

| Origin | North America | South Africa |

Introduction to Jerky and Biltong

Jerky and biltong are popular methods of preserving meat through dehydration, each with unique preparation techniques and flavors. Jerky typically involves thinly sliced, marinated meat dried quickly at low temperatures, while biltong uses thicker cuts cured with vinegar and spices before air-drying.

- Jerky Origin - Jerky originates from Native American cultures and is traditionally made from lean beef strips marinated with a variety of spices and dried at controlled temperatures.

- Biltong Origin - Biltong has South African roots, involving curing meat in vinegar and spices before slow air-drying, resulting in a more tender texture.

- Flavor Profiles - Jerky offers a smoky, spicy flavor due to its marination and drying process, whereas biltong tends to have a tangy, rich taste from vinegar and natural fermentation.

Both jerky and biltong represent distinct culinary traditions that use dehydration to create long-lasting, flavorful meat snacks.

Origins and Cultural Background

| Jerky | Originates from Native American culinary traditions, particularly from tribes in the Great Plains region, and involves thinly sliced, salted, and smoked meat for preservation. Popularized in the United States, jerky reflects a method designed for portability and longevity, often using beef but also other meats. Its cultural significance ties to North American outdoor and survivalist practices. |

| Biltong | Stems from Southern African heritage, particularly among the indigenous Khoisan and Dutch settlers, evolving as a cured and air-dried meat rich in spices like coriander and vinegar. Biltong's preparation and seasoning reflect South African biodiversity and traditional preservation techniques adapted to local climates. It holds strong cultural value as a staple snack and shares a communal eating tradition in Southern Africa. |

Meat Selection and Preparation

Jerky making typically involves using lean cuts of beef such as top round or flank steak, which are trimmed of fat to ensure longer shelf life and a chewier texture. Biltong preparation uses thicker cuts like silverside or topside, often marinated in vinegar and spices to tenderize the meat and enhance flavor before drying. Proper slicing against the grain in jerky contrasts with the thicker, grain-aligned strips in biltong, influencing texture and drying time.

Seasoning and Flavor Profiles

Jerky making often features bold, smoky flavors with marinades utilizing soy sauce, Worcestershire, and liquid smoke to enhance savory notes. Biltong relies on simpler seasoning blends such as salt, vinegar, coriander, and black pepper, creating a tangy and aromatic flavor distinct to South African cuisine. The drying process also influences flavor absorption, with jerky's thinner slices allowing for more intense seasoning penetration compared to the thicker cuts used in biltong.

Drying and Dehydration Methods

Jerky making typically involves marinating thin strips of meat and drying them at a low temperature using electric dehydrators or ovens, resulting in a lean, dry texture. The dehydration process in jerky emphasizes consistent airflow and heat application to efficiently remove moisture while preserving protein structure.

Biltong drying relies on air drying meat strips cured with vinegar and spices, often hanging in a controlled environment with low humidity and moderate temperatures, which slows dehydration and enhances flavor development. This traditional South African method promotes enzymatic activity during drying, creating a tender texture distinct from jerky. The slower moisture removal in biltong retains more juiciness compared to the rapid drying used in jerky making.

Texture and Final Product Comparison

Jerky features a tougher, chewier texture due to thin slicing and high heat dehydration, resulting in a dense and dry final product. Biltong undergoes air drying with thicker cuts and vinegar marination, producing a tender, moist, and flavorful dried meat.

- Jerky Texture - Thin slices and rapid dehydration create a firm, chewy bite typical of American-style dried meat.

- Biltong Texture - Thicker strips and slow air drying retain moisture, yielding a softer, more succulent texture.

- Final Product Comparison - Jerky tends to be drier and denser, while biltong is moister with a more pronounced meat flavor due to its curing process.

Storage and Shelf Life

How do storage and shelf life differ between jerky and biltong? Jerky typically has a longer shelf life due to its lower moisture content and often vacuum-sealed packaging, allowing it to last several months to a year when stored in a cool, dry place. Biltong, with its higher moisture content and natural curing process, usually requires refrigeration and lasts only a few weeks to a couple of months to maintain optimal quality.

Nutritional Differences

Jerky typically contains higher sodium levels due to the curing process with salt and additives, which can impact its overall nutritional profile. Biltong, dried through air-curing without excessive salt, generally offers a leaner option with lower sodium content and retains more natural protein.

Both jerky and biltong provide rich sources of protein, but biltong often includes additional vitamins and minerals because it is less processed and free from preservatives. The fat content in biltong can be slightly higher, contributing to a different nutritional balance compared to the leaner jerky varieties.

Cost and Equipment Considerations

Jerky making requires specialized dehydrators or ovens that can maintain consistent low temperatures, often increasing initial equipment costs. Biltong preparation demands additional tools such as curing boxes and air-drying setups, which may lead to higher complexity but potentially lower energy expenses.

- Jerky Equipment Costs - High-quality electric dehydrators suitable for jerky production typically range from $50 to $300, depending on size and features.

- Biltong Equipment Requirements - Biltong making involves using curing chambers and fans, which can add to initial setup time but use less electricity than continuous dehydrators.

- Cost Efficiency - Jerky machines consume more power for extended drying periods, whereas biltong's air-drying method reduces ongoing energy costs but requires more manual monitoring.

Related Important Terms

Wet Curing vs. Dry Curing

Jerky making primarily involves wet curing, where meat is marinated in a seasoned liquid to enhance flavor and tenderness before dehydration, while biltong relies on dry curing, using salt and spices applied directly to the meat to draw out moisture and preserve it. Wet curing in jerky results in a chewier texture and intensified taste, whereas biltong's dry curing produces a drier, more tender product with a distinctively rich flavor profile.

Vinegar Brining Technique

Vinegar brining in biltong making enhances flavor and acts as a natural preservative by lowering pH, which inhibits bacterial growth during dehydration, while jerky typically relies on a salt and sugar cure without vinegar. This acidic brine not only tenderizes the meat but also contributes to biltong's distinct tangy taste, contrasting with jerky's generally sweeter, spiced profile.

Cold Air Drying (Biltong Style)

Cold air drying in biltong making preserves meat quality by using lower temperatures and longer drying times, which retain natural enzymes and result in a tender, flavorful product. This method contrasts with traditional jerky making that often employs hotter air for faster drying, potentially sacrificing texture and nutritional value.

Sugar-Free Jerky Seasoning

Sugar-free jerky seasoning enhances the natural flavor of meat without added sugars, offering a healthier alternative to traditional biltong mixes that often include sugar or vinegar for curing. This seasoning method preserves protein content and supports low-carb diets, making sugar-free jerky ideal for fitness enthusiasts and keto followers seeking nutrient-dense, long-lasting snacks.

Snap Test (Texture Standard)

Jerky making emphasizes a tough, leathery texture evaluated by a firm snap test, ensuring durability and chewiness, while biltong targets a softer, more pliable texture with a tender snap breaking easily to signal optimal moisture content. The snap test serves as a critical quality control measure, reflecting differences in dehydration methods and seasoning that influence protein fiber structure and overall mouthfeel.

Nitrite-Free Preservation

Jerky making typically relies on curing agents like nitrites for preservation and flavor, while biltong is often prepared using vinegar and salt, enabling nitrite-free preservation that reduces potential health risks. This natural curing method in biltong offers a safer alternative for dried meat enthusiasts seeking chemical-free options without compromising shelf life.

Fat Cap Retention

Jerky making typically involves thinly sliced meat with minimal fat, resulting in less fat cap retention compared to biltong, which is traditionally prepared using thicker cuts with the fat cap intact to enhance flavor and moisture during dehydration. Retaining the fat cap in biltong preserves essential oils and improves texture, making it distinct from the leaner, dryer profile of jerky.

Humidity-Controlled Dehydration

Jerky making relies on low humidity dehydration, using temperatures between 130degF and 160degF to quickly remove moisture and inhibit bacterial growth, resulting in a denser, chewier texture. In contrast, biltong employs humidity-controlled dehydration at lower temperatures around 90degF to 125degF with higher humidity levels, preserving tenderness and enhancing flavor through a slower drying process that minimizes case hardening.

Marination Time Optimization

Jerky making typically requires a marination time of 6 to 24 hours to enhance flavor penetration and ensure proper curing, while biltong benefits from a shorter marination period of 4 to 12 hours due to its vinegar-based marinade that accelerates tenderizing. Optimizing marination time according to these specific drying techniques maximizes meat texture and taste retention during dehydration.

Jerky Making vs Biltong for dried meat. Infographic

cookingdiff.com

cookingdiff.com