Oven drying removes moisture by applying consistent heat, which can cause some loss of nutrients and texture but is faster and more cost-effective. Freeze drying preserves the structural integrity and nutritional content by freezing the product and sublimating the ice under vacuum, making it ideal for sensitive materials. Choosing between oven drying and freeze drying depends on the desired quality, cost, and application of the dehydrated product.

Table of Comparison

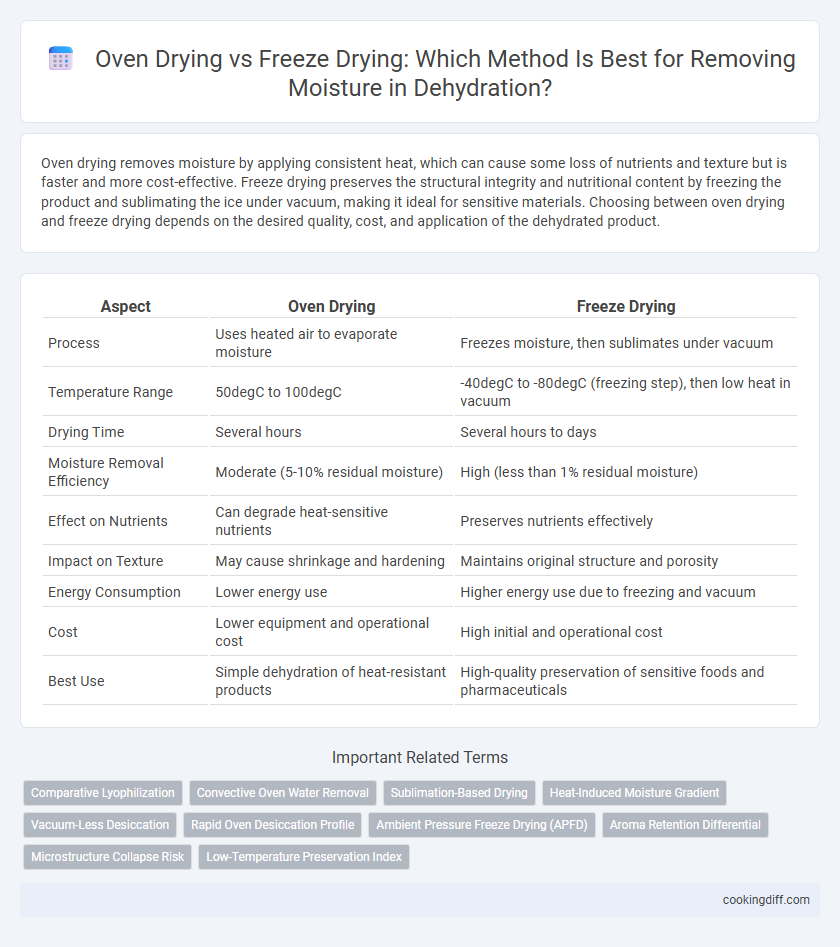

| Aspect | Oven Drying | Freeze Drying |

|---|---|---|

| Process | Uses heated air to evaporate moisture | Freezes moisture, then sublimates under vacuum |

| Temperature Range | 50degC to 100degC | -40degC to -80degC (freezing step), then low heat in vacuum |

| Drying Time | Several hours | Several hours to days |

| Moisture Removal Efficiency | Moderate (5-10% residual moisture) | High (less than 1% residual moisture) |

| Effect on Nutrients | Can degrade heat-sensitive nutrients | Preserves nutrients effectively |

| Impact on Texture | May cause shrinkage and hardening | Maintains original structure and porosity |

| Energy Consumption | Lower energy use | Higher energy use due to freezing and vacuum |

| Cost | Lower equipment and operational cost | High initial and operational cost |

| Best Use | Simple dehydration of heat-resistant products | High-quality preservation of sensitive foods and pharmaceuticals |

Understanding Oven Drying and Freeze Drying Techniques

Oven drying removes moisture by applying consistent heat, causing water to evaporate from the material, which is efficient for many laboratory and industrial applications. Freeze drying extracts moisture through sublimation by freezing the sample and reducing pressure, preserving structural and chemical integrity of sensitive substances.

- Oven drying heats samples typically between 50-105degC - facilitating rapid moisture removal but may degrade heat-sensitive compounds.

- Freeze drying involves freezing and vacuum application - allowing moisture to transition from solid to vapor without passing through liquid phase, maintaining product quality.

- Oven drying is cost-effective and simple - while freeze drying is more complex and expensive but yields superior preservation of texture and bioactivity.

How Moisture Removal Works: Oven vs Freeze Drying

Oven drying removes moisture by applying continuous heat, causing water to evaporate from the material's surface and interior at temperatures typically between 50degC and 100degC. Freeze drying, or lyophilization, involves freezing the material and then reducing surrounding pressure to allow frozen water to sublimate directly from ice to vapor. This sublimation process preserves structural integrity and nutrients better than the thermal evaporation used in oven drying.

Efficiency of Moisture Removal: Oven Drying Compared to Freeze Drying

How does the efficiency of moisture removal compare between oven drying and freeze drying? Oven drying uses heated air to rapidly evaporate water, making it faster but potentially causing nutrient loss and texture changes. Freeze drying removes moisture by sublimation under low temperature and pressure, preserving food quality more effectively but requiring longer processing times and higher energy consumption.

Impact on Food Quality: Texture and Flavor Differences

Oven drying removes moisture through heat, which can cause shrinkage and toughening of food texture, often resulting in a denser final product. The high temperatures may also degrade delicate flavors, leading to a cooked or slightly altered taste profile.

Freeze drying preserves the food's cellular structure by sublimating ice directly to vapor, maintaining original texture and rehydration qualities. It retains flavor compounds better than oven drying, providing a fresher and more natural taste experience.

Nutrient Retention: Which Method Preserves More?

Oven drying often leads to significant nutrient degradation, particularly of heat-sensitive vitamins such as vitamin C and B-complex vitamins, due to prolonged exposure to high temperatures. Freeze drying, by contrast, preserves nutrient content more effectively by sublimating moisture at low temperatures, maintaining the integrity of heat-sensitive compounds.

Studies indicate that freeze drying retains up to 90-95% of vitamins and antioxidants compared to oven drying's 50-70% retention rate. This significant difference makes freeze drying the preferred method when maximizing nutrient preservation is essential for dehydrating fruits and vegetables.

Energy Consumption: Oven Drying vs Freeze Drying

Oven drying consumes significantly more energy due to prolonged exposure to high temperatures ranging from 50degC to 150degC, leading to higher electricity usage. Freeze drying, operating at low temperatures under vacuum, requires substantial energy mainly for freezing and maintaining a vacuum environment.

Energy consumption in oven drying can exceed 2 kWh per kilogram of moisture removed, whereas freeze drying may consume between 4 to 10 kWh per kilogram due to the combined need for refrigeration and vacuum pumps. Despite freeze drying's higher energy requirements, it preserves nutritional quality and texture better than oven drying. The choice between these methods depends on balancing energy costs with desired product quality and shelf life.

Cost Considerations for Home and Commercial Use

Oven drying generally incurs lower initial costs and is more accessible for home use due to common household appliances, making it a cost-effective option for small-scale moisture removal. Freeze drying requires expensive specialized equipment and higher energy consumption, which increases operational costs but provides superior preservation, making it more suitable for commercial applications that demand high-quality results. For large-scale commercial drying, the higher upfront investment in freeze drying can be offset by its efficiency and product value, whereas oven drying remains ideal for budget-conscious home users.

Suitable Foods for Oven Drying and Freeze Drying

Oven drying is best suited for foods with low water content like herbs, nuts, and thinly sliced vegetables, where heat can effectively remove moisture without compromising texture. Freeze drying preserves the structural integrity and nutrients of delicate foods such as berries, meats, and full fruits by freezing them before sublimating the ice content.

- Oven drying suits sturdy, low-moisture foods - herbs and nuts dry evenly with consistent heat application.

- Freeze drying excels for high-moisture, delicate foods - berries and meats retain shape and nutrition.

- Oven drying is less effective for thick or juicy foods - heat can cause shrinkage and nutrient loss.

Choosing the method depends on food type, moisture content, and desired preservation quality.

Storage Life: Shelf Stability After Drying

| Drying Method | Storage Life | Shelf Stability |

|---|---|---|

| Oven Drying | Typically preserves food for 1 to 3 months under proper conditions | Moderate shelf stability due to potential retention of residual moisture and heat exposure |

| Freeze Drying | Extends storage life up to 25 years or more when sealed airtight | High shelf stability as moisture is removed at low temperatures, preventing spoilage and oxidation |

Related Important Terms

Comparative Lyophilization

Oven drying removes moisture by applying consistent heat, which may cause nutrient loss or texture changes, while freeze drying, a form of lyophilization, preserves nutritional content and structural integrity through sublimation under low temperature and vacuum conditions. Comparative analysis shows freeze drying maintains superior product quality but requires higher energy input and longer processing time compared to oven drying's faster, cost-effective approach.

Convective Oven Water Removal

Convective oven drying removes moisture by circulating hot air around the material, accelerating evaporation through heat transfer and air movement, typically operating at temperatures between 50degC and 100degC. This method is energy-efficient for heat-stable products but may cause quality degradation in heat-sensitive materials compared to freeze drying, which uses sublimation under low temperature and pressure.

Sublimation-Based Drying

Sublimation-based drying, primarily utilized in freeze drying, involves the direct transition of water from solid ice to vapor without passing through the liquid phase, preserving the structural integrity and nutrients of sensitive materials. Oven drying relies on evaporation, which heats the product and can cause nutrient degradation and textural changes due to prolonged exposure to elevated temperatures.

Heat-Induced Moisture Gradient

Oven drying removes moisture through sustained heat, creating a heat-induced moisture gradient that accelerates water evaporation but can cause nutrient degradation and texture changes. Freeze drying, by contrast, removes moisture via sublimation at low temperatures, preserving structural integrity and nutritional content by minimizing heat exposure and moisture gradients.

Vacuum-Less Desiccation

Oven drying removes moisture through heated air circulation, accelerating water evaporation but often causing nutrient loss and texture changes; freeze drying, by sublimating ice under vacuum, preserves food quality and nutrients but requires expensive vacuum equipment. Vacuum-less desiccation methods focus on maximizing moisture removal without vacuum systems, offering a cost-effective alternative to freeze drying while maintaining better nutrient retention and texture compared to traditional oven drying.

Rapid Oven Desiccation Profile

Oven drying offers a rapid oven desiccation profile by using controlled heat to quickly evaporate moisture, achieving faster drying times compared to the slower sublimation process of freeze drying. This method is particularly effective for heat-stable materials requiring swift moisture removal without the need for low-temperature preservation.

Ambient Pressure Freeze Drying (APFD)

Oven drying removes moisture by applying heat at atmospheric pressure, which can degrade heat-sensitive nutrients and alter texture, while Ambient Pressure Freeze Drying (APFD) extracts moisture through sublimation under atmospheric pressure, preserving nutritional content and structural integrity more effectively. APFD offers energy-efficient dehydration with minimal thermal damage, making it ideal for sensitive food products and pharmaceuticals requiring retention of bioactive compounds.

Aroma Retention Differential

Oven drying typically causes significant aroma loss due to prolonged exposure to high temperatures, which can degrade volatile compounds responsible for fragrance. Freeze drying preserves aroma more effectively by sublimating moisture under low temperatures and vacuum, maintaining the integrity of heat-sensitive aromatic molecules.

Microstructure Collapse Risk

Oven drying exposes materials to high temperatures that can cause microstructure collapse, leading to shrinkage and texture degradation. Freeze drying removes moisture by sublimation at low temperatures, preserving the microstructure and maintaining product integrity.

Oven Drying vs Freeze Drying for removing moisture. Infographic

cookingdiff.com

cookingdiff.com