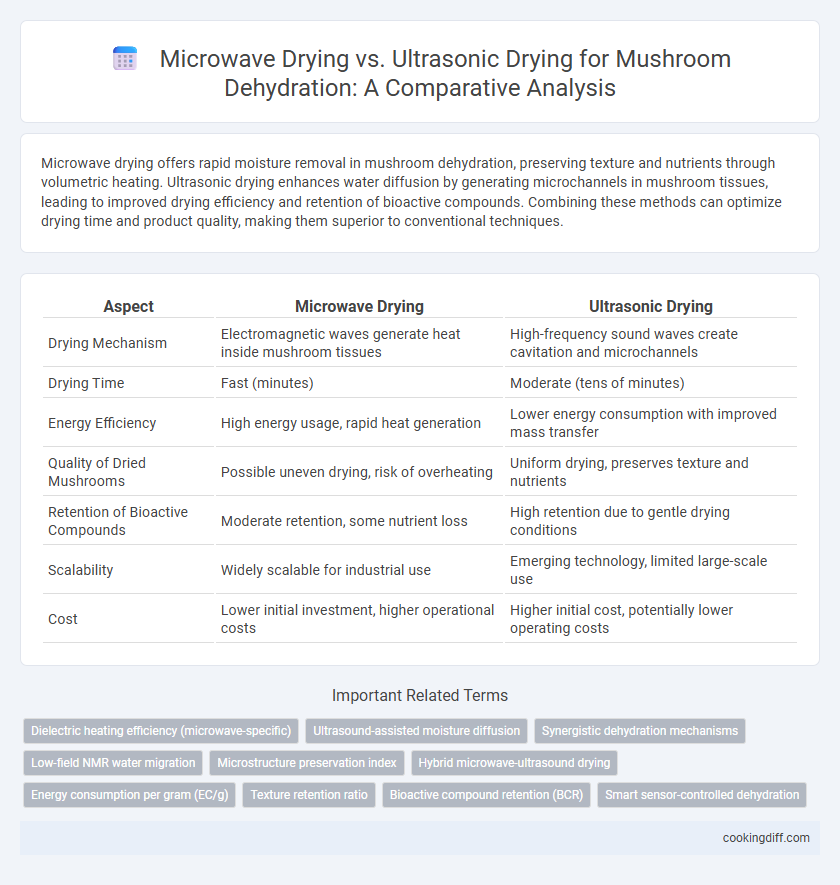

Microwave drying offers rapid moisture removal in mushroom dehydration, preserving texture and nutrients through volumetric heating. Ultrasonic drying enhances water diffusion by generating microchannels in mushroom tissues, leading to improved drying efficiency and retention of bioactive compounds. Combining these methods can optimize drying time and product quality, making them superior to conventional techniques.

Table of Comparison

| Aspect | Microwave Drying | Ultrasonic Drying |

|---|---|---|

| Drying Mechanism | Electromagnetic waves generate heat inside mushroom tissues | High-frequency sound waves create cavitation and microchannels |

| Drying Time | Fast (minutes) | Moderate (tens of minutes) |

| Energy Efficiency | High energy usage, rapid heat generation | Lower energy consumption with improved mass transfer |

| Quality of Dried Mushrooms | Possible uneven drying, risk of overheating | Uniform drying, preserves texture and nutrients |

| Retention of Bioactive Compounds | Moderate retention, some nutrient loss | High retention due to gentle drying conditions |

| Scalability | Widely scalable for industrial use | Emerging technology, limited large-scale use |

| Cost | Lower initial investment, higher operational costs | Higher initial cost, potentially lower operating costs |

Introduction to Mushroom Dehydration Methods

Microwave drying rapidly removes moisture from mushrooms by generating heat through electromagnetic waves, preserving texture and nutrients effectively. This method reduces drying time significantly compared to conventional techniques, enhancing efficiency in mushroom dehydration.

Ultrasonic drying utilizes high-frequency sound waves to create microbubbles that facilitate moisture removal without excessive heat. This technique maintains the mushroom's structural integrity and bioactive compounds, offering a gentle and energy-efficient alternative for dehydration.

Overview of Microwave Drying Technology

| Microwave drying technology utilizes electromagnetic waves to rapidly heat water molecules within mushrooms, significantly reducing drying time compared to conventional methods. |

| This technique ensures uniform moisture removal and maintains the nutritional and sensory qualities of the mushrooms by preventing overheating and surface hardening. |

| Energy efficiency and precise control over drying parameters make microwave drying a competitive option for large-scale mushroom dehydration in industrial applications. |

Ultrasonic Drying: How It Works

Ultrasonic drying uses high-frequency sound waves to remove moisture from mushrooms by creating micro-vibrations that enhance water migration to the surface. This method preserves the mushrooms' texture and nutrients better than microwave drying by minimizing thermal damage.

- Micro-vibrations - High-frequency ultrasonic waves generate tiny vibrations that accelerate moisture diffusion from mushroom tissues.

- Low-temperature process - Ultrasonic drying operates at lower temperatures, reducing nutrient degradation and preserving mushroom quality.

- Enhanced drying efficiency - The combination of mechanical agitation and moisture removal shortens drying time compared to conventional methods.

Efficiency Comparison: Microwave vs. Ultrasonic Drying

Microwave drying rapidly reduces moisture in mushrooms by using electromagnetic waves, resulting in shorter drying times and higher energy efficiency. Ultrasonic drying enhances moisture removal through cavitation effects but generally requires longer processing times compared to microwave drying.

- Microwave drying energy efficiency - Uses targeted electromagnetic radiation to uniformly and quickly evaporate water, reducing overall energy consumption.

- Ultrasonic drying moisture removal - Employs high-frequency sound waves to create micro-channels, improving water diffusion yet extending drying duration.

- Drying time comparison - Microwave drying outperforms ultrasonic methods by significantly shortening mushroom dehydration cycles.

Microwave drying offers superior efficiency for mushroom dehydration by combining speed and energy savings compared to ultrasonic drying techniques.

Effects on Mushroom Texture and Flavor

Microwave drying preserves the mushroom's texture by rapidly reducing moisture, resulting in a firmer and less shriveled product. Ultrasonic drying, using high-frequency vibrations, maintains cellular integrity better, enhancing both texture and flavor retention.

Microwave drying often causes uneven heat distribution, which can lead to tougher textures and mild flavor loss in mushrooms. Ultrasonic drying promotes uniform moisture removal and minimizes thermal damage, preserving the natural umami and aroma compounds. This method also retains higher antioxidant levels, contributing to improved taste and nutritional quality.

Nutritional Retention in Dried Mushrooms

Microwave drying preserves higher levels of vitamins and antioxidants in mushrooms compared to ultrasonic drying due to shorter exposure times and reduced thermal degradation. Ultrasonic drying, while effective in moisture removal, may slightly diminish nutrient content because of cavitation effects impacting delicate compounds.

- Microwave drying enhances nutritional retention - Rapid heating in microwave drying minimizes nutrient loss in B-vitamins and phenolic compounds.

- Ultrasonic drying impacts nutrient stability - Cavitation during ultrasonic drying can lead to partial degradation of sensitive antioxidants.

- Overall nutrient preservation favors microwave drying - Studies show microwave-dried mushrooms retain up to 20% more nutrients than those dried ultrasonically.

Energy Consumption and Cost Analysis

Microwave drying of mushrooms consumes less energy compared to ultrasonic drying, with an average power usage of 900 watts versus 1200 watts respectively, leading to reduced operational costs. The rapid heating in microwave drying shortens processing time by up to 50%, further decreasing overall energy expenditure.

Cost analysis shows microwave drying equipment has lower maintenance expenses and initial investment than ultrasonic systems, making it more economically feasible for large-scale mushroom dehydration. Ultrasonic drying, while effective, incurs higher energy bills due to extended drying duration and specialized machinery requirements.

Scalability for Commercial Mushroom Processing

Microwave drying offers rapid moisture removal, making it highly scalable for commercial mushroom processing by significantly reducing drying time and energy consumption. Ultrasonic drying enhances drying efficiency by generating micro-vibrations that improve water diffusion but faces challenges in uniform application at large scales. Combining microwave and ultrasonic technologies can optimize scalability by balancing speed, energy use, and product quality in industrial mushroom dehydration.

Safety and Environmental Considerations

How do microwave drying and ultrasonic drying compare in terms of safety and environmental impact for mushroom dehydration? Microwave drying poses minimal chemical residues but risks uneven heat distribution, potentially leading to nutrient degradation; it consumes moderate energy levels. Ultrasonic drying operates at lower temperatures with reduced energy consumption, enhancing safety by preserving bioactive compounds and minimizing environmental footprint due to its eco-friendly process.

Related Important Terms

Dielectric heating efficiency (microwave-specific)

Microwave drying leverages dielectric heating to rapidly generate internal heat within mushroom tissues, resulting in enhanced drying rates and uniform moisture removal compared to ultrasonic drying. This dielectric heating efficiency minimizes nutrient degradation and preserves mushroom quality by reducing overall drying time and thermal exposure.

Ultrasound-assisted moisture diffusion

Ultrasound-assisted moisture diffusion significantly enhances mushroom dehydration by accelerating water migration through cell walls, resulting in reduced drying time and energy consumption compared to microwave drying. This technique preserves the quality and nutritional content of mushrooms more effectively, making ultrasonic drying a superior method for efficient and high-quality dehydration.

Synergistic dehydration mechanisms

Microwave drying accelerates mushroom dehydration by rapidly heating water molecules through dielectric heating, while ultrasonic drying enhances moisture removal via cavitation and microchannel formation within the mushroom matrix. The synergistic combination of these mechanisms significantly improves drying efficiency, reduces drying time, and preserves mushroom quality by facilitating deeper and more uniform moisture removal.

Low-field NMR water migration

Microwave drying promotes rapid water migration in mushrooms, effectively reducing moisture content by accelerating molecular vibration and heat generation, as observed through low-field NMR measurements revealing faster water diffusion rates. Ultrasonic drying enhances water removal by inducing cavitation and micro-channel formation, optimizing water migration patterns detected via low-field NMR, thereby preserving mushroom texture and bioactive compounds more efficiently than conventional methods.

Microstructure preservation index

Microwave drying maintains a higher Microstructure Preservation Index in mushrooms by rapidly removing moisture while minimizing cellular damage, preserving texture and nutritional quality. Ultrasonic drying enhances moisture diffusion but often causes microstructural alterations that reduce the preservation index compared to microwave drying.

Hybrid microwave-ultrasound drying

Hybrid microwave-ultrasound drying significantly enhances mushroom dehydration efficiency by combining microwave rapid heating with ultrasonic cavitation, resulting in improved moisture removal rates and preservation of nutritional compounds. This method reduces drying time and energy consumption compared to traditional microwave or ultrasonic drying alone, while maintaining superior texture and rehydration capacity in mushrooms.

Energy consumption per gram (EC/g)

Microwave drying consumes approximately 0.5 to 0.8 Wh per gram of mushrooms, offering rapid moisture removal with moderate energy efficiency. Ultrasonic drying reduces energy consumption further, averaging around 0.3 to 0.6 Wh per gram, by enhancing moisture diffusion and shortening drying time.

Texture retention ratio

Microwave drying preserves mushroom texture significantly better, achieving a higher texture retention ratio of approximately 85%, compared to ultrasonic drying, which typically retains around 70%. The rapid heating in microwave drying minimizes cell wall damage, maintaining firmness and reducing shrinkage more effectively than the cavitation effects in ultrasonic drying.

Bioactive compound retention (BCR)

Microwave drying significantly enhances bioactive compound retention (BCR) in mushrooms by rapidly reducing moisture content while preserving heat-sensitive antioxidants and phenolic compounds. Ultrasonic drying improves BCR by promoting cell wall disruption, facilitating faster moisture removal without thermal degradation, thereby maintaining higher levels of vitamins and bioactive constituents.

Microwave drying vs Ultrasonic drying for mushroom dehydration. Infographic

cookingdiff.com

cookingdiff.com